مع الاعتماد السريع لتقنية الليزر في التصنيع الصناعي, دعاية, ومعالجة الالكترونيات الدقيقة, الطلب على التشغيل المستقر والأداء عالي الدقة في معدات القطع والنقش بالليزر1 يستمر في الارتفاع. و نظام تبريد فعال وموثوق2 أصبح ضروريًا لضمان الأداء وطول العمر.

من بين طرق التبريد المختلفة, المبردات الصناعية3 تبرز باعتبارها الحل الأكثر فعالية. من خلال توفير التحكم الدقيق في درجة الحرارة وتبديد الحرارة بكفاءة, أصبحت المبردات الآن لا غنى عنها في أنظمة الليزر. كمؤسسة رائدة في مجال التكنولوجيا الفائقة متخصصة في التحكم الدقيق في درجة الحرارة, أسلوب التبريد4 توفر مبردات عاكسة DC صغيرة متقدمة مصممة خصيصًا لتلبية متطلبات التبريد لتطبيقات الليزر.

متطلبات التبريد لمعدات الليزر5

كيفية عمل القطع والنقش بالليزر

آلات الليزر تولد عوارض ذات كثافة عالية من الطاقة6 التي يتم تركيزها من خلال الأنظمة البصرية للقطع, نقش, أو وضع علامة على المواد. هذه العملية, في حين دقيقة وفعالة, تنتج كميات كبيرة من الحرارة.

لماذا تولد أنظمة الليزر الحرارة؟

المكونات الرئيسية مثل مصدر الليزر7, مزود الطاقة, وتعمل العدسات البصرية تحت أحمال عالية وتنتج الحرارة بشكل مستمر. ليزر الألياف وليزر ثاني أكسيد الكربون, على الرغم من كفاءتها العالية, لا تزال تولد خسائر حرارية كبيرة. إذا لم يتم تبديد الحرارة بشكل فعال, يمكن أن يؤدي إلى عدم الاستقرار, انخفاض الانتاج, أو حتى تلف المعدات الدائم.

أهمية التبريد

مستقر تبريد8 يضمن إخراج ليزر ثابت, يمتد عمر المعدات, ويحسن دقة المعالجة. للحمل العالي, تطبيقات طويلة الأمد, تلعب المبردات دورًا حاسمًا في منع الانجراف الحراري, تشويه الشعاع, ومشاكل الأداء الأخرى.

دور ومبدأ المبرد

كيف يقلل المبرد من درجة حرارة الليزر

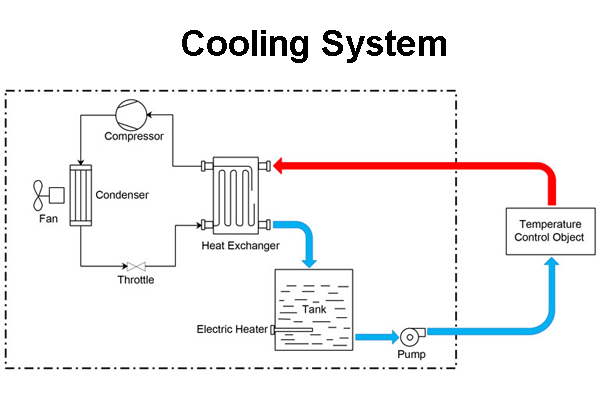

تعمل المبردات على خفض درجة حرارة سائل التبريد المتداول عبر دورة التبريد, ثم قم بتوصيله إلى دائرة تبريد الليزر. يمتص المبرد الحرارة من المكونات ويعود إلى المبرد لإعادة تبريده, تشكيل أ نظام الحلقة المغلقة9.

مبدأ العمل

يتكون المبرد من أ ضاغط, مكثف, صمام توسع, المبخر, مضخة, والخزان10 أثناء العملية, يقوم الضاغط بضغط مادة التبريد, الذي يطلق الحرارة في المكثف. بعد الاختناق والتبخر, يمتص المبرد الحرارة من ماء التبريد, خفض درجة حرارته.

مبردات Coolingstyle ميزة ضواغط عاكسة ذات كفاءة عالية تعمل بالتيار المستمر11 وأنظمة ذكية للتحكم في درجة الحرارة, ضمان ± 0.1 درجة مئوية دقة12, مثالي لأنظمة الليزر التي تتطلب أداءً فائق الاستقرار.

المكونات والوظائف الرئيسية

- ضاغط13: قلب المبرد, قيادة تداول المبردات.

- المبخر: يمتص الحرارة من الماء لتحقيق التبريد.

- مكثف: يطلق الحرارة في البيئة الخارجية.

- مضخة: يقوم بتدوير سائل التبريد من خلال النظام وجهاز الليزر.

- نظام التحكم14: يراقب درجة الحرارة, تدفق, والضغط من أجل التشغيل المستقر.

اختيار وتكوين المبرد المناسب

مطابقة سعة المبرد مع طاقة الليزر

يجب أن تكون قدرة التبريد 1.2-1.5 مرة من قوة الليزر المقدرة15 لضمان هامش الأمان. الحمل الحراري هو الحد الأدنى من سعة المبرد لتبريد الليزر, يتطلب الليزر بقوة 1500 واط مبردًا بقوة 1800 واط على الأقل.

اعتبارات قدرة التبريد

الى جانب السلطة, تعد قدرة المبرد على الحفاظ على تبريد مستقر في ظل درجات الحرارة المحيطة المرتفعة أمرًا بالغ الأهمية. CoalingStyle M160 سلسلة المبرد الصناعي16 يسلم 1600قدرة التبريد W ويتضمن وظائف التدفئة, ضمان التشغيل المستقر عبر الظروف الموسمية والبيئية.

اختيار العلامة التجارية والنموذج

مع العديد من الخيارات في السوق, يعد اختيار الشركة المصنعة التي تتمتع بالتكنولوجيا والخدمة المثبتة أمرًا حيويًا. أسلوب التبريد, مع أكثر من عقد من الخبرة في التبريد الصغير17, لقد بنى سمعة قوية في مجال الليزر, طبي, والصناعات العلمية من خلال العرض منتجات موثوقة ودعم شامل لما بعد البيع18.

استخدام وصيانة مبرد الليزر

إرشادات الاستخدام اليومي

- تأكد من امتلاء خزان المياه قبل بدء التشغيل.

- ضع الوحدة في بيئة جيدة التهوية بعيدًا عن أشعة الشمس المباشرة.

- استخدم الماء النقي أو مضاد التجمد لمنع القشور.

- لا تعمل أبدًا بدون ماء.

الصيانة الدورية

إجراء عمليات تفتيش شهرية لأداء الضاغط, المعلمات الكهربائية, ونظافة المكثف. قم بمعالجة العيوب على الفور لمنع التوقف عن العمل.

استكشاف الأخطاء وإصلاحها الشائعة

- لا يوجد تأثير التبريد: قد يشير إلى مكثف متسخ أو سائل تبريد غير كافي.

- تسرب المياه: تحقق من توصيلات الأنابيب.

- إنذار: الرجوع إلى رموز الخطأ للتشخيص.

تم تجهيز المبردات Coolingstyle مع ميزات الحماية متعددة المستويات19 مثل إنذار تدفق المياه20, تحذيرات من ارتفاع درجة الحرارة, وحماية الضاغط الزائد للتشغيل الآمن.

التنظيف والعناية

- تنظيف المرشحات والمكثفات بانتظام.

- التحقق من وجود شوائب في خزانات المياه والأنابيب.

- للتخزين على المدى الطويل, استنزاف وتجفيف خزان المياه.

خاتمة

مبردات الليزر ضرورية ل مستقر, فعال, والتشغيل الدقيق21 من معدات القطع والنقش بالليزر. من خلال الحفاظ على ثبات درجة الحرارة, فهي تحمي موثوقية المعدات وتعزز جودة المعالجة.

مع التركيز القوي على تكنولوجيا التحكم في درجة حرارة البيئة الدقيقة, لقد اكتسبت شركة Coolingstyle خبرة واسعة في دعم صناعة الليزر. لدينا وضعت بشكل مستقل دي سي العاكس مبردات22 معترف بها على نطاق واسع ل كفاءة, ذكاء, والموثوقية.

سوف تستمر شركة Coolingstyle في قيادة الابتكار لتقديم خدمات أكثر ذكاءً, أكثر كفاءة في استخدام الطاقة, وحلول تبريد مخصصة لصناعة الليزر.

للاستفسارات حول الاختيار أو الحلول المخصصة, يرجى الاتصال بـ Coolingstyle. نحن على استعداد لتزويدك ب حل التبريد وقفة واحدة.

- استكشف هذا الرابط للتعرف على نصائح الصيانة الأساسية التي تعمل على تحسين أداء وعمر معدات الليزر لديك. ↩︎

- اكتشف كيف يمكن لنظام التبريد المناسب أن يعزز بشكل كبير كفاءة عمليات القطع بالليزر وطول عمرها. ↩︎

- استكشف هذا الرابط لفهم كيفية تعزيز المبردات الصناعية للكفاءة والدقة في تطبيقات الليزر. ↩︎

- اكتشف المبردات المبتكرة من Coolingstyle والمصممة خصيصًا لأنظمة الليزر, ضمان الأداء الأمثل والموثوقية. ↩︎

- يعد فهم متطلبات التبريد أمرًا بالغ الأهمية للحفاظ على كفاءة معدات الليزر وطول عمرها الافتراضي. ↩︎

- يمكن أن يؤدي استكشاف الحزم ذات الكثافة العالية من الطاقة إلى تعزيز معرفتك بعمليات القطع والنقش بالليزر. ↩︎

- يعد فهم مصدر الليزر أمرًا بالغ الأهمية لفهم كيفية تأثير توليد الحرارة على أداء الليزر. ↩︎

- يمكن أن يساعدك استكشاف أهمية التبريد على تعلم كيفية الحفاظ على أداء الليزر الأمثل وطول العمر. ↩︎

- سيساعدك استكشاف هذا المفهوم على فهم كفاءة وفعالية المبردات في التطبيقات المختلفة. ↩︎

- يعد فهم هذه المكونات أمرًا ضروريًا لتحسين أداء وكفاءة المبرد. ↩︎

- يمكن أن يكشف استكشاف هذه التقنية عن كيفية تحسين توفير الطاقة والأداء في أنظمة التبريد. ↩︎

- يعد فهم هذه الدقة أمرًا بالغ الأهمية لتطبيقات مثل أنظمة الليزر, ضمان الأداء الأمثل. ↩︎

- يعد فهم وظيفة الضاغط أمرًا بالغ الأهمية لتحسين أداء وكفاءة المبرد. ↩︎

- يمكن أن يؤدي استكشاف أنظمة التحكم إلى تعزيز معرفتك بتنظيم درجة الحرارة واستقرار النظام في المبردات. ↩︎

- يعد فهم قدرة التبريد اللازمة لأشعة الليزر أمرًا بالغ الأهمية لتحقيق الأداء الأمثل والسلامة. ↩︎

- يمكن أن يوفر استكشاف سلسلة M160 رؤى حول حلول التبريد الموثوقة للتطبيقات الصناعية. ↩︎

- إن استكشاف التبريد الصغير سيوفر نظرة ثاقبة لتطبيقاته وابتكاراته, حاسمة بالنسبة للصناعات مثل الطبية والعلمية. ↩︎

- إن فهم أهمية المنتجات الموثوقة ودعم ما بعد البيع يمكن أن يعزز قرارات الشراء الخاصة بك ويضمن الرضا على المدى الطويل. ↩︎

- إن فهم هذه الميزات يمكن أن يعزز معرفتك بالسلامة والكفاءة في عمليات التبريد بالليزر. ↩︎

- سيساعدك استكشاف هذا الموضوع على ضمان الأداء الأمثل ومنع المشكلات المحتملة مع المبرد الخاص بك. ↩︎

- يمكن أن يساعدك فهم هذه الفوائد على تحسين عمليات القطع بالليزر وتحسين الإنتاجية الإجمالية. ↩︎

- يمكن أن يؤدي استكشاف مزايا المبردات ذات العاكس DC إلى تحسين كفاءة الطاقة والأداء في حلول التبريد الخاصة بك. ↩︎