يعد التبريد الفعال أمرًا ضروريًا للحفاظ على أداء وأشعة ليزر CO2 RF. كما أوضح فيليب بريستون, رئيس العلم, التحكم في درجة الحرارة يلعب دورًا رئيسيًا في تثبيت إخراج الليزر. هذا مهم بشكل خاص مع تحويل الليزر فقط 10-20% من الطاقة في الضوء, مع تحول الطاقة المتبقية إلى حرارة النفايات. دون تبديد حرارة فعال, يمكن أن تؤثر ارتفاع درجات الحرارة في منطقة تصريف الليزر على الأداء سلبًا, استقرار الإخراج, وعمر.

لماذا التبريد ضروري لليزر CO2 RF

تأثير الحرارة على استقرار الليزر

- الآثار الحرارية: ارتفاع درجات الحرارة في منطقة تصريف الليزر النشاط الجزيئي, استنفاد مستويات الطاقة العلوية وتوسيع الطيف الجزيئي CO2. هذا ينتج عنه:

- انخفاض طاقة الإخراج

- أداء ليزر غير مستقر

- نطاق درجة الحرارة المثالي: تشير الأبحاث إلى أن الليزر RF CO2 يحقق كفاءة التحويل الكهروضوئية المثلى عند الحفاظ على درجة حرارة غاز الليزر بين 400ك و 500 كيلو.

طرق التبريد الشائعة

- تبديد الحرارة المبرد بالهواء

- تستخدم في المقام الأول ل الليزر منخفض الطاقة (≤100W).

- يعتمد على المشجعين لتبديد الحرارة ولكنه أقل فعالية لمخرجات الطاقة الأعلى.

- تبديد الحرارة المبرد بالماء

- مناسب ل جميع نطاقات الطاقة, خاصة الليزر عالية الطاقة.

- ينقل نفايات الحرارة إلى المبرد عن طريق التوصيل, ضمان تبريد أكثر كفاءة.

إطالة عمر أنبوب ليزر ثاني أكسيد الكربون مع مبردات الماء

CoalingStyle 4يو رف مبرد يقدم حلاً قويًا للتبريد بالليزر. تبريد الماء المناسب:

- يطيل عمر أنابيب الليزر.

- يعزز الكفاءة من خلال الحفاظ على درجات حرارة مستقرة.

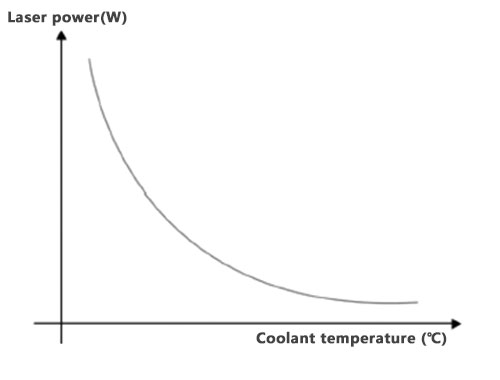

تأثير درجة حرارة التبريد على طاقة الليزر

وفق قانون التبريد في نيوتن (ф = A * * ΔT):

- كلما زاد اختلاف درجة الحرارة (ΔT) بين المبرد ومنطقة التفريغ, كلما كان التبريد أكثر كفاءة.

- أ 1زيادة درجة مئوية في درجة حرارة المبرد يمكن أن تقلل من طاقة الليزر 0.5-1%.

اعتبارات رئيسية:

- المخاطر المفرطة: قد تسبب درجات حرارة سائل التبريد المنخفضة جدًا تكثيفًا على سطح الليزر, تؤثر على الوظيفة وربما تقلل من عمر الليزر.

- درجة حرارة سائل التبريد المثلى: يوصي CollingStyle 25± 2 درجة مئوية, مع تعديلات للتغيرات الموسمية:

- صيف: تجنب التكثيف عن طريق الإعداد إلى 28± 2 درجة مئوية.

- شتاء: الحفاظ على الحد الأدنى لدرجة حرارة سائل التبريد 5-10درجة مئوية لمنع التجمد.

اختيار مبرد الماء المناسب

لموازنة قوة الليزر والاستقرار, يوفر CollingStyle مجموعة من مبردات المياه المصممة خصيصًا لصناعة الليزر:

ميزات المبردات:

- قدرة التبريد: من 200ث إلى 1200W.

- استقرار درجة الحرارة: ± 0.1 درجة مئوية للتحكم الدقيق.

- مدمجة وخفيفة الوزن: سهولة التكامل في أنظمة الليزر.

- كفاءة الطاقة: انخفاض استهلاك القوة الكهربائية يقلل من التكاليف التشغيلية.

- سهولة الصيانة: تصميم سهل الاستخدام للتشغيل الخالي من المتاعب.

خيارات مبرد CoolingStyle

- 420W و 580W سعة تبريد

- 400W و 500W سعة تبريد

- 4يو رف مبرد

- مدمجة وفعالة للتطبيقات المتوسطة.

- 1000W و 1200W سعة تبريد

- 5يو رف مبرد

- مصممة لأنظمة الليزر الصناعية عالية الطاقة.

توصيات تحديد درجة الحرارة

- الظروف القياسية: اضبط درجة حرارة المبرد على 25± 2 درجة مئوية لاستقرار الليزر الأمثل.

- التعديلات الموسمية:

- صيف: 28± 2 درجة مئوية لمنع التكثيف.

- شتاء: الحفاظ على أ درجة حرارة الدوران من 5-10 درجة مئوية لتوفير الطاقة وتجنب التجميد.

- استخدام التجمد: استخدم التجمد من الدرجة المهنية إذا لزم الأمر; تجنب الإيثانول لأنه قد يلحق الضرر بالنظام.

خاتمة

التبريد المناسب ضروري للحفاظ أداء الليزر والاستقرار. مبردات المياه المتقدمة في ColdingStyle, مع التحكم الدقيق في درجة الحرارة وكفاءة الطاقة, مصممة لتلبية المطالب الفريدة لليزر CO2 RF. عن طريق اختيار المبرد الأيمن والحفاظ على درجات حرارة سائل التبريد المثلى, يمكن للمستخدمين تمديد عمر أنابيب الليزر, تحسين طاقة الإخراج, وتحقيق نتائج متسقة في التطبيقات التحويلية والصناعية.

لمزيد من المعلومات حول اختيار المبرد, يمكنك زيارة هذه المدونة للرجوع إليها: