Avec l'adoption rapide de la technologie laser dans la fabrication industrielle, publicité, et traitement électronique de précision, la demande d'un fonctionnement stable et de performances de haute précision dans équipement de découpe et de gravure laser1 continue d'augmenter. Un système de refroidissement efficace et fiable2 est devenu indispensable pour garantir à la fois performance et longévité.

Parmi les différentes méthodes de refroidissement, refroidisseurs industriels3 se démarquer comme la solution la plus efficace. En fournissant un contrôle précis de la température et une dissipation efficace de la chaleur, les refroidisseurs sont désormais indispensables dans les systèmes laser. En tant qu'entreprise de haute technologie leader spécialisée dans le contrôle de température de précision, Style de refroidissement4 propose des refroidisseurs avancés à micro-onduleur CC conçus spécifiquement pour répondre aux exigences de refroidissement des applications laser.

Exigences de refroidissement des équipements laser5

Comment fonctionnent la découpe et la gravure au laser

Les machines laser génèrent poutres à haute densité énergétique6 qui sont focalisés via des systèmes optiques pour couper, graver, ou marquer des matériaux. Ce processus, tout en étant précis et efficace, produit des quantités importantes de chaleur.

Pourquoi les systèmes laser génèrent de la chaleur

Des composants clés tels que le source laser7, alimentation, et les lentilles optiques fonctionnent sous des charges élevées et produisent de la chaleur en continu. Lasers à fibre et lasers CO₂, malgré leur grande efficacité, génèrent encore des pertes thermiques importantes. Si la chaleur n'est pas dissipée efficacement, cela peut conduire à l'instabilité, rendement réduit, ou même des dommages permanents à l'équipement.

Importance du refroidissement

Écurie refroidissement8 assure une sortie laser constante, prolonge la durée de vie de l'équipement, et améliore la précision du traitement. Pour charge élevée, applications de longue durée, les refroidisseurs jouent un rôle essentiel dans la prévention de la dérive thermique, distorsion du faisceau, et autres problèmes de performances.

Le rôle et le principe d'un refroidisseur

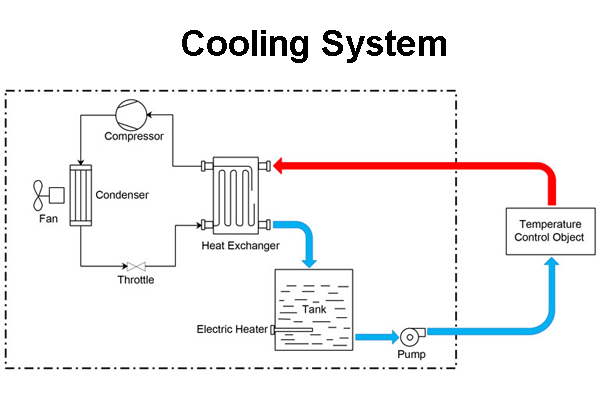

Comment un refroidisseur réduit la température du laser

Les refroidisseurs abaissent la température du liquide de refroidissement en circulation via un cycle de réfrigération, puis livrez-le au circuit de refroidissement du laser. Le liquide de refroidissement absorbe la chaleur des composants et retourne au refroidisseur pour être refroidi., formant un système en boucle fermée9.

Principe de fonctionnement

Un refroidisseur est composé d'un Nous offrons à nos clients une expérience unique et des services couvrant l'ensemble du cycle de vie du produit, du concept à la conception, condenseur, Soupape de détente, évaporateur, Système de refroidissement du corps, et réservoir10 Pendant le fonctionnement, le compresseur comprime le réfrigérant, qui dégage de la chaleur dans le condenseur. Après étranglement et évaporation, le réfrigérant absorbe la chaleur de l'eau de refroidissement, abaisser sa température.

Les refroidisseurs de refroidissement fonctionnalité compresseurs à inverseur CC à haut rendement11 et systèmes intelligents de contrôle de la température, garantissant ± 0,1 ° C12, idéal pour les systèmes laser nécessitant des performances ultra-stables.

Composants et fonctions clés

- Compresseur13: Le cœur du refroidisseur, piloter la circulation du réfrigérant.

- Évaporateur: Absorbe la chaleur de l'eau pour obtenir un refroidissement.

- Condenseur: Libère de la chaleur dans le milieu extérieur.

- Pompe: Fait circuler le liquide de refroidissement à travers le système et le dispositif laser.

- Système de contrôle14: Surveille la température, couler, et pression pour un fonctionnement stable.

Choisir et configurer le bon refroidisseur

Adaptation de la capacité du refroidisseur à la puissance du laser

La capacité de refroidissement doit être 1.2–1,5 fois la puissance laser nominale15 pour garantir une marge de sécurité. Chaque refroidisseur a une courbe de puissance frigorifique, un laser de 1 500 W nécessite au moins un refroidisseur de 1 800 W.

Considérations sur la capacité de refroidissement

Outre le pouvoir, la capacité du refroidisseur à maintenir un refroidissement stable à des températures ambiantes élevées est essentielle. Style de refroidissement Chiller industriel de la série M16016 livre 1600W puissance frigorifique et comprend des fonctions de chauffage, assurer un fonctionnement stable quelles que soient les conditions saisonnières et environnementales.

Sélection de marque et de modèle

Avec de nombreuses options sur le marché, Il est essentiel de sélectionner un fabricant doté d'une technologie et d'un service éprouvés.. Style de refroidissement, avec plus d'une décennie d'expertise dans micro-réfrigération17, s'est bâti une solide réputation dans le domaine du laser, médical, et les industries scientifiques en proposant produits fiables et support après-vente complet18.

Utilisation et entretien d'un refroidisseur laser

Directives d'utilisation quotidienne

- Assurez-vous que le réservoir d'eau est rempli avant le démarrage.

- Placez l'appareil dans un environnement bien ventilé, à l'abri de la lumière directe du soleil.

- Utilisez de l'eau purifiée ou de l'antigel pour éviter le tartre.

- Ne jamais fonctionner sans eau.

Entretien régulier

Effectuer des inspections mensuelles des performances du compresseur, paramètres électriques, et propreté du condenseur. Corrigez immédiatement les anomalies pour éviter les temps d’arrêt.

Dépannage courant

- Aucun effet rafraîchissant: Peut indiquer un condenseur sale ou un manque de réfrigérant.

- Fuite d'eau: Vérifier les connexions des tuyaux.

- Alarmes: Reportez-vous aux codes d'erreur pour le diagnostic.

Les refroidisseurs Coolingstyle sont équipés de fonctionnalités de protection à plusieurs niveaux19 il effectue d'autres tâches supplémentaires dans le système alarmes de débit d'eau20, avertissements de température élevée, et protection contre les surcharges du compresseur pour un fonctionnement sûr.

Nettoyage et entretien

- Nettoyer régulièrement les filtres et les condenseurs.

- Vérifiez les impuretés dans les réservoirs d’eau et les tuyaux.

- Pour un stockage à long terme, vidanger et sécher le réservoir d'eau.

Les refroidisseurs avec ce compresseur miniature ont les avantages ci-dessous

Les refroidisseurs laser sont essentiels pour le écurie, efficace, et un fonctionnement précis21 d'équipements de découpe et de gravure laser. En maintenant la stabilité de la température, ils garantissent la fiabilité des équipements et améliorent la qualité du traitement.

Avec un fort accent sur technologie de contrôle de la température du micro-environnement, Coolingstyle a accumulé une vaste expérience dans le soutien à l'industrie du laser. Notre développement indépendant Refroidisseurs à onduleurs DC22 sont largement reconnus pour leur Efficacité, intelligence, et fiabilité.

Coolingstyle continuera à stimuler l'innovation pour offrir des services plus intelligents, plus économe en énergie, et solutions de refroidissement personnalisées pour l'industrie laser.

Pour toute demande de sélection ou de solutions personnalisées, veuillez contacter Coolingstyle. Nous sommes prêts à vous fournir un solution de refroidissement unique.

- Explorez ce lien pour découvrir des conseils de maintenance essentiels qui améliorent les performances et la durée de vie de votre équipement laser.. ↩︎

- Découvrez comment un système de refroidissement approprié peut augmenter considérablement l'efficacité et la longévité de vos opérations de découpe laser.. ↩︎

- Explorez ce lien pour comprendre comment les refroidisseurs industriels améliorent l'efficacité et la précision des applications laser.. ↩︎

- Découvrez les refroidisseurs innovants de Coolingstyle adaptés aux systèmes laser, garantissant des performances et une fiabilité optimales. ↩︎

- Comprendre les exigences de refroidissement est crucial pour maintenir l’efficacité et la longévité des équipements laser. ↩︎

- L'exploration de faisceaux à haute densité d'énergie peut améliorer vos connaissances des processus de découpe et de gravure au laser. ↩︎

- Comprendre la source laser est crucial pour comprendre l'impact de la génération de chaleur sur les performances du laser. ↩︎

- Explorer l'importance du refroidissement peut vous aider à apprendre comment maintenir des performances et une longévité optimales du laser.. ↩︎

- L'exploration de ce concept vous aidera à comprendre l'efficience et l'efficacité des refroidisseurs dans diverses applications.. ↩︎

- Comprendre ces composants est crucial pour optimiser les performances et l'efficacité du refroidisseur.. ↩︎

- L'exploration de cette technologie peut révéler comment elle améliore les économies d'énergie et les performances des systèmes de refroidissement.. ↩︎

- Comprendre cette précision est crucial pour des applications telles que les systèmes laser, Assurer des performances optimales. ↩︎

- Comprendre le fonctionnement du compresseur est crucial pour optimiser les performances et l'efficacité du refroidisseur.. ↩︎

- L'exploration des systèmes de contrôle peut améliorer vos connaissances sur la régulation de la température et la stabilité du système dans les refroidisseurs.. ↩︎

- Comprendre la capacité de refroidissement nécessaire aux lasers est crucial pour des performances et une sécurité optimales. ↩︎

- L'exploration de la série M160 peut fournir un aperçu des solutions de refroidissement fiables pour les applications industrielles. ↩︎

- L'exploration de la micro-réfrigération fournira un aperçu de ses applications et de ses innovations, crucial pour des industries comme la médecine et la science. ↩︎

- Comprendre l'importance de produits fiables et d'un service après-vente peut améliorer vos décisions d'achat et garantir une satisfaction à long terme.. ↩︎

- Comprendre ces fonctionnalités peut améliorer vos connaissances en matière de sécurité et d'efficacité dans les opérations des refroidisseurs laser.. ↩︎

- L'exploration de ce sujet vous aidera à garantir des performances optimales et à prévenir les problèmes potentiels avec votre refroidisseur.. ↩︎

- Comprendre ces avantages peut vous aider à optimiser vos processus de découpe laser et à améliorer votre productivité globale.. ↩︎

- Explorer les avantages des refroidisseurs à onduleur CC peut conduire à une meilleure efficacité énergétique et à de meilleures performances dans vos solutions de refroidissement. ↩︎