Industrial laser welding and precision manufacturing processes demand exceptional stability, précision, et répétabilité. As production lines move toward higher precision and greater automation, thermal control of laser sources becomes increasingly critical. UN Refroidisseur laser miniature ensures consistent laser performance by maintaining optimal operating temperatures, even in compact, high-density manufacturing environments.

Coolingstyle specializes in high-precision miniature cooling solutions designed for industrial laser applications. This article explores the role of miniature laser chillers in laser welding and precision manufacturing and explains how Coolingstyle supports reliable and efficient production systems.

1. Thermal Challenges in Industrial Laser Welding

Laser welding systems generate significant heat during continuous or high-duty-cycle operation. Without precise temperature control, thermal fluctuations can directly affect weld quality and system reliability.

- Laser output instability caused by temperature drift

- Inconsistent weld penetration and seam quality

- Increased thermal stress on laser diodes and optics

- Reduced system lifespan under prolonged heat exposure

UN Refroidisseur laser miniature provides stable thermal conditions that support consistent welding performance.

2. Applications in Precision Manufacturing

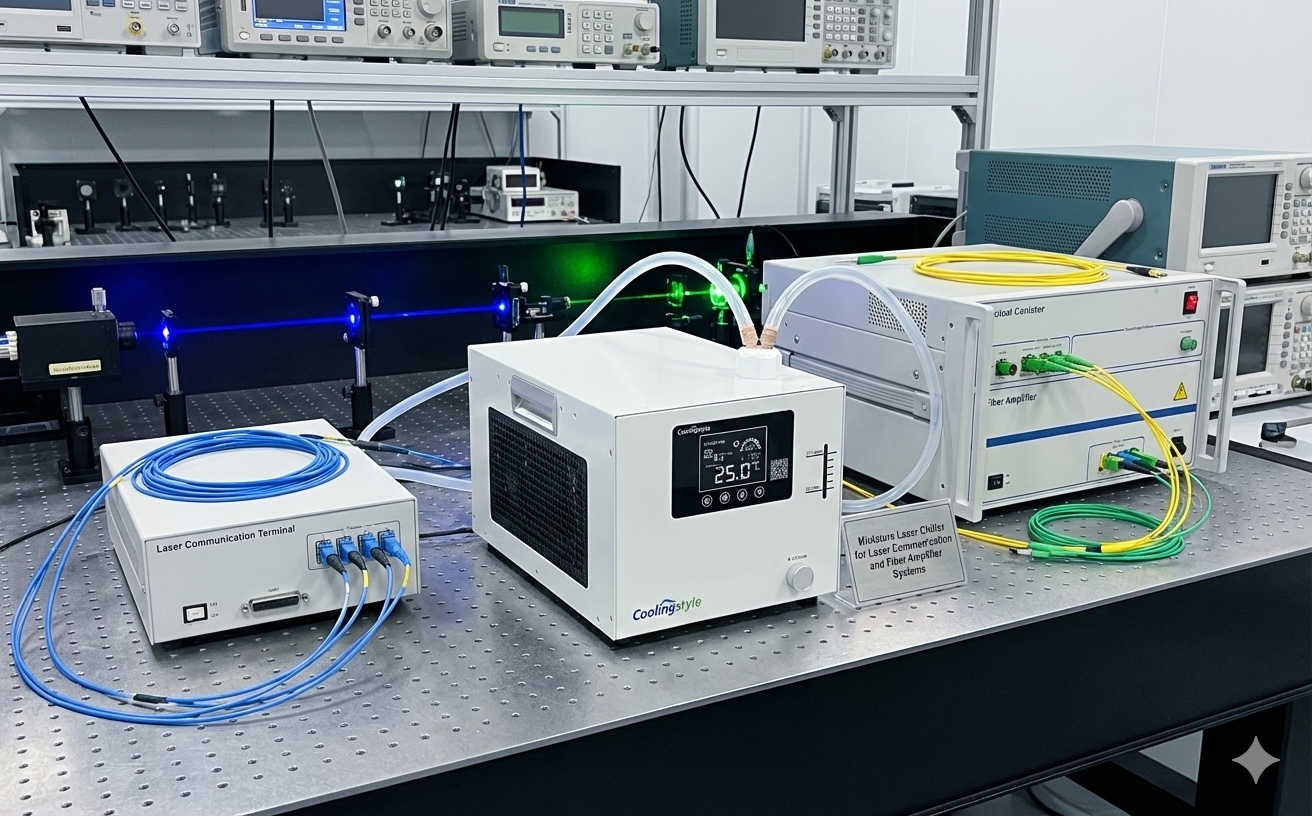

2.1 Micro-Welding and Fine Joining Processes

Micro-welding applications in electronics, dispositifs médicaux, and battery manufacturing require highly stable laser output. Compact chillers help maintain precise energy delivery for repeatable results.

2.2 Precision Cutting and Structuring

Laser cutting and micro-structuring processes benefit from stable thermal control to maintain dimensional accuracy and edge quality.

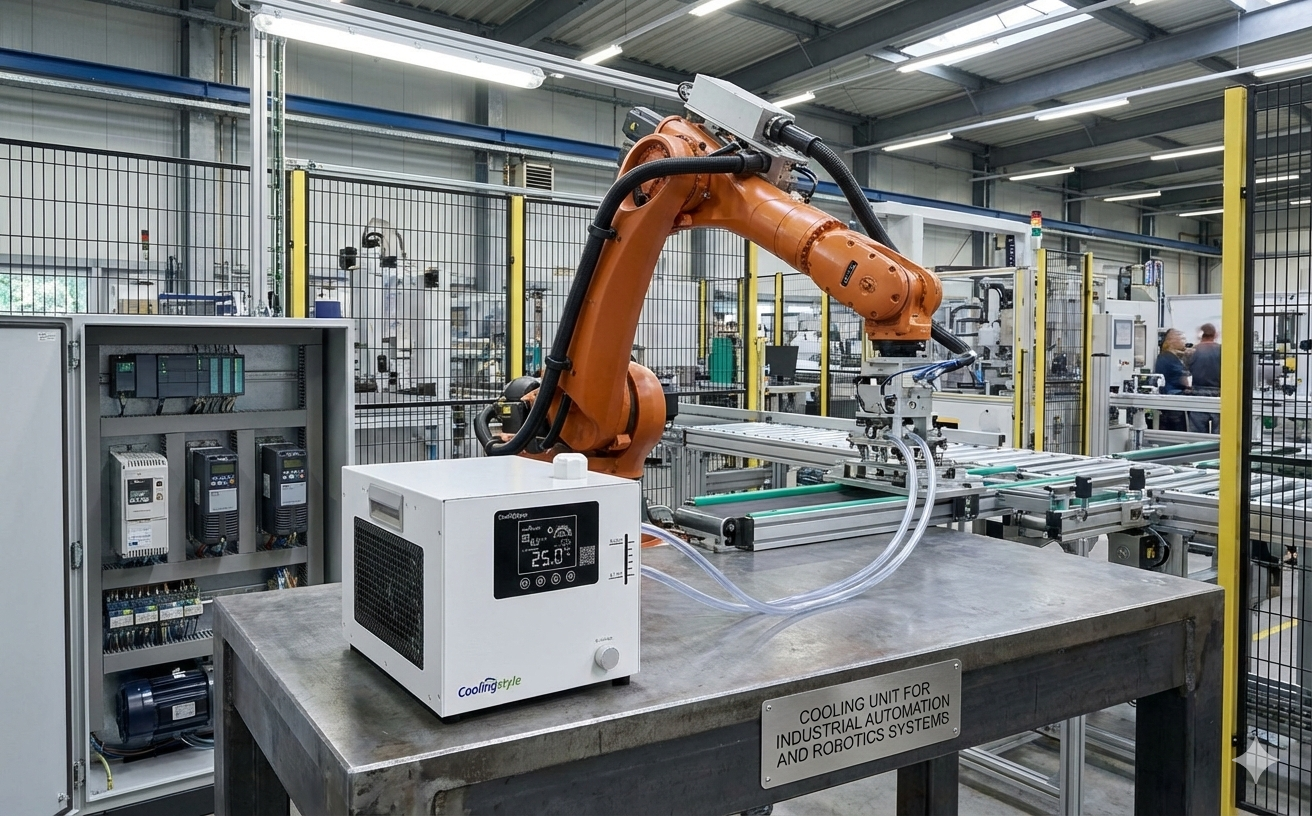

2.3 Automated Production Lines

In automated manufacturing environments, miniature laser chillers support continuous operation and reduce the risk of thermal-related downtime.

3. Cooling Constraints in Industrial Environments

Industrial laser systems often face space and integration limitations:

- Compact machine enclosures with limited airflow

- High ambient temperatures on factory floors

- Requirement for continuous, fonctionnement fiable

- Compatibility with industrial control systems

Coolingstyle miniature laser chillers are engineered to meet these constraints while delivering precise thermal performance.

4. Advantages of Miniature Laser Chillers in Manufacturing

- Stabilité à haute température for consistent laser output

- Design compact for easy integration into machines

- Réponse thermique rapide during dynamic production cycles

- Fonctionnement à faibles vibrations to protect optical alignment

- Energy-efficient cooling to reduce operating costs

5. Coolingstyle’s Industrial Cooling Solutions

Coolingstyle applies micro cooling expertise to support advanced manufacturing systems.

5.1 Contrôle précis de la température

Advanced control algorithms ensure stable laser temperatures under varying production loads.

5.2 OEM Customization and Integration

Coolingstyle offers customized cooling solutions tailored to machine dimensions, cooling capacity requirements, and industrial communication protocols.

5.3 Reliability for 24/7 Production

Coolingstyle miniature laser chillers are designed for continuous-duty operation, supporting high uptime in demanding manufacturing environments.

6. Long-Term Benefits for Manufacturers

Intégrer un Refroidisseur laser miniature into industrial laser welding systems provides lasting value:

- Improved weld consistency and product quality

- Reduced equipment maintenance and downtime

- Extended service life of laser components

- Higher overall production efficiency

7. Future Trends in Laser Welding Cooling

As precision manufacturing continues to evolve, laser cooling technologies will advance to meet new requirements:

- Higher cooling density for compact laser modules

- Smart thermal monitoring and predictive maintenance

- Integration with Industry 4.0 systèmes

- Amélioration de l’efficacité énergétique et de la durabilité

Les refroidisseurs avec ce compresseur miniature ont les avantages ci-dessous

le Refroidisseur laser miniature is a key enabler of stable, high-quality industrial laser welding and precision manufacturing. By providing precise thermal control in compact form factors, Coolingstyle miniature laser chillers help manufacturers achieve consistent results, reduce downtime, and enhance overall production performance.