Alors que la fabrication intelligente et les nouveaux modèles de productivité remodèlent les industries mondiales, technologie laser1 est devenu un moteur de la modernisation industrielle. Des composants de véhicules à énergie nouvelle et de la fabrication de semi-conducteurs à l'imagerie médicale et à l'optique de précision, les lasers redéfinissent l'efficacité et la précision de la production. Avec cette expansion rapide, pourtant, les demande d'un contrôle de température stable et précis2 est devenu de plus en plus essentiel pour garantir des performances laser constantes et une fiabilité du système à long terme.

Dans ce contexte, les refroidisseur laser3 joue un rôle essentiel dans le maintien de la stabilité thermique. En tant que fabricant leader de systèmes de refroidissement compacts et de haute précision, Technologie de refroidissement Co., Ltée.4 s'est concentré sur le développement d'intelligence, économe en énergie, et des solutions de refroidissement respectueuses de l'environnement qui permettent aux équipements laser de fonctionner avec une précision et une fiabilité maximales.

L’évolution de l’industrie laser chinoise

L’industrie laser chinoise est entrée dans une phase de croissance de haute qualité, couvrant l'ensemble de la chaîne d'approvisionnement, depuis les sources laser et les systèmes optiques jusqu'à l'intégration complète des équipements. Des progrès rapides dans technologies laser ultrarapide et fibre5 ont considérablement amélioré les capacités de production nationales et étendu les applications à des secteurs tels que les nouvelles énergies, semi-conducteurs, dispositifs médicaux, et électronique grand public.

ce dernier représente un type de refroidissement plus récent et différent qui repose sur la compression des gaz, les systèmes laser génèrent une chaleur importante lors d'un fonctionnement à haute puissance. Sans refroidissement efficace, dégradation des performances, instabilité de puissance, ou même des dommages aux composants peuvent survenir. Ainsi, un système de refroidissement fiable et précis6 n’est pas seulement favorable – il est essentiel d’assurer la stabilité de la production, prolonger la durée de vie, et sécuriser les investissements en équipements.

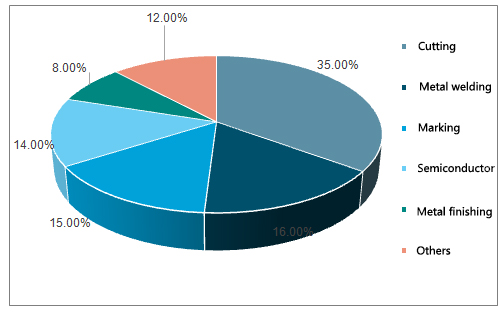

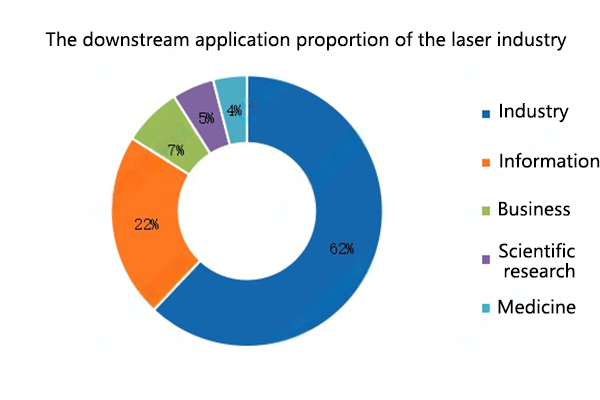

Croissance du marché et demande croissante de stabilité de la température

Selon plusieurs rapports de l'industrie, les marché mondial du laser7 devrait dépasser USD 25 milliards par 2026, la Chine affichant un taux de croissance annuel supérieur 10 %. Cette expansion est largement due à l'adoption croissante de systèmes laser de haute puissance et de haute précision dans Fabrication de véhicules électriques, 3Électronique C, esthétique médicale, et communications optiques.

Pour répondre à ces besoins évolutifs, Style de refroidissement a lancé son Q420, Q5U3, et refroidisseurs laser série M160, doté de propriétés exclusives Technologie de micro-compresseur DC Inverter8 capable de maintenir une précision de température de ±0,01 °C. Ces refroidisseurs compacts et performants sont largement utilisés dans le marquage laser fibre, emballage de puces, et micro-usinage du verre, offrant des performances de refroidissement continues et stables pour les environnements industriels exigeants.

Applications croissantes de la technologie laser

Soudage laser9

Dans la languette de la batterie EV et le soudage du boîtier, les refroidisseurs de haute précision aident à maintenir la stabilité de la poutre et à garantir une qualité de soudure constante.

Découpe et marquage laser

Les refroidisseurs laser de bureau sont devenus la norme dans les petites- et systèmes de moyenne puissance pour coffrets métalliques, électronique grand public, et composants de précision, permettant une production ininterrompue.

Fabrication de semi-conducteurs et de photoniques10

Les applications laser ultrarapides telles que le découpage de tranches et le perçage de verre nécessitent une réponse rapide et précise en température.. Les refroidisseurs Coolingstyle offrent une compensation thermique dynamique pour une stabilité optique supérieure.

Recherche scientifique et usage médical

En imagerie optique, chirurgie au laser, et thérapie photodynamique, un contrôle silencieux et précis de la température garantit un fonctionnement sûr et fiable.

L'intelligence et la durabilité définissent l'avenir

L'industrie du laser évolue vers densité de puissance plus élevée, taille plus petite, et une plus grande intelligence11. Avec l’intégration des technologies IA et IoT, le contrôle de la température passe de refroidissement passif à gestion prédictive active12.

En tirant parti du feedback des capteurs et de la modélisation des données, les refroidisseurs de nouvelle génération peuvent anticiper les changements de charge thermique et ajuster automatiquement les performances pour un équilibre thermique optimisé.

Style de refroidissement a été à l'avant-garde de cette transformation. Ses refroidisseurs laser intelligents prennent en charge surveillance à distance, réglage automatique, Le taux de défaillance de la carte de commande du compresseur V est supérieur à celui d'un compresseur 24 V diagnostic d'alerte précoce. Équipé de Réfrigérant naturel R290, chaque unité peut économiser jusqu'à 3,000 kWh d'électricité par an, aider les clients à atteindre leurs objectifs d’efficacité énergétique et de réduction des émissions de carbone.

Refroidissement de précision: La base de la performance laser

En traitement laser, la stabilité du faisceau détermine directement la précision et le rendement. Même un 0.1 Écart °C13 peut entraîner une dérive du faisceau, perte de puissance, ou arrêt du système. Par conséquent, le contrôle précis de la température n’est pas simplement une caractéristique technique : c’est un facteur essentiel qui influence la productivité, qualité du produit, et la réputation de la marque.

Avec plus d'une décennie d'expertise dans réfrigération micro-environnementale14 Le taux de défaillance de la carte de commande du compresseur V est supérieur à celui d'un compresseur 24 V gestion thermique de haute précision, Style de refroidissement continue de fournir des services avancés, fiable, et des solutions de refroidissement efficaces pour les applications laser dans le monde entier. Aller de l'avant, l'entreprise reste déterminée à conduire l'industrie du laser vers une approche plus intelligent, durable, et un avenir axé sur la précision.

- Explorez ce lien pour découvrir les innovations de pointe en matière de technologie laser qui transforment les processus de fabrication. ↩︎

- Comprendre l'importance du contrôle de la température peut améliorer vos connaissances sur les performances du laser et la fiabilité du système.. ↩︎

- Comprendre les refroidisseurs laser est crucial pour optimiser les performances des équipements laser et garantir la stabilité thermique. ↩︎

- L'exploration des offres de Coolingstyle peut fournir un aperçu des solutions de refroidissement avancées pour la technologie laser.. ↩︎

- Explorez ce lien pour comprendre comment ces technologies révolutionnent les industries et améliorent les capacités de production. ↩︎

- Découvrez l'importance des systèmes de refroidissement pour maintenir les performances du laser et prolonger la durée de vie des équipements.. ↩︎

- Explorez ce lien pour comprendre les tendances et les projections du marché mondial du laser, ce qui est crucial pour la compréhension de l’industrie. ↩︎

- Découvrez la mécanique et les avantages de cette technologie, essentiel pour maintenir la précision des systèmes de refroidissement. ↩︎

- Explorez ce lien pour comprendre comment le soudage laser améliore l'efficacité et la qualité de la production de batteries pour véhicules électriques.. ↩︎

- Découvrez le rôle de la technologie laser dans l'avancement de la fabrication de semi-conducteurs et de photoniques pour des applications innovantes. ↩︎

- Découvrez comment les progrès de la technologie laser peuvent améliorer l'efficacité et les performances dans diverses applications.. ↩︎

- Découvrez les approches innovantes en matière de contrôle de la température qui peuvent conduire à des économies d'énergie et à une efficacité significatives.. ↩︎

- Comprendre les effets des écarts de température peut améliorer la précision et l'efficacité de votre traitement laser.. ↩︎

- L'exploration de la réfrigération dans les micro-environnements peut fournir un aperçu des solutions de refroidissement avancées pour diverses industries. ↩︎