Precisione controllo della temperatura1non è più solo per i laboratori. Dai sistemi laser all'ingranaggio di raffreddamento portatile, Micro refrigeratore2S stanno ridefinendo l'efficienza in spazi limitati.

UN Micro refrigeratore2 è un dispositivo di raffreddamento compatto che integra la refrigerazione basata sul compressore per fornire accurata ed efficiente controllo della temperatura1 in ambienti vincolati nello spazio.

Man mano che l'attrezzatura sensibile alla temperatura diventa più compatta, Micro refrigeratore2s si sono evoluti in componenti critici in molti settori. Ma cosa li fa esattamente tick? Ci immerciamo nella struttura, funzione, e valore di Micro refrigeratore2s nel raffreddamento di precisione.

Cos'è un Micro refrigeratore2

L'attrezzatura moderna si sta riducendo di dimensioni, Ma i loro carichi termici rimangono intensi.

UN Micro refrigeratore2 è un Sistema di refrigerazione in miniatura3 Progettato per applicazioni in cui dimensioni, peso, E la precisione conta di più.

Come funziona?

UN Micro refrigeratore2 funziona utilizzando un compressore inverter in miniatura, Un ciclo di refrigerante a circuito chiuso, e un sistema di circolazione dell'acqua per estrarre e dissipare il calore in modo efficiente. Nonostante le sue dimensioni, Funziona proprio come un refrigeratore industriale su vasta scala, solo più intelligente e più piccolo.

| Funzione| Descrizione del micro refrigeratore|

|—————-|———————————————|

| Metodo di raffreddamento | Ciclo di refrigerazione a base di compressore4 |

| Medio| Soluzione di acqua o glicole|

| Bersaglio| Attrezzatura compatta o zone localizzate|

Quali sono i componenti principali all'interno di un micro refrigeratore?

Anche nella sua piccola forma, Un micro refrigeratore è costruito con un sistema completo.

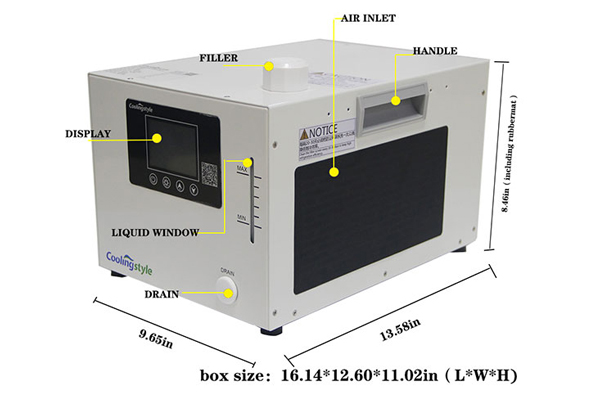

Un micro refrigeratore in genere include un file Compressore inverter CC5, scambiatori di calore, pompa dell'acqua, serbatoio dell'acqua, e a Unità di controllo della temperatura6.

Scomposizione dei componenti chiave

Compressore

Il cuore del sistema, in genere a Micro DC Inverter7 tipo, che regola la velocità per abbinare la domanda di raffreddamento.

Condensatore & Evaporatore

Responsabile di Scambio di calore8—Strasferimento del calore dall'acqua al refrigerante e fuori in aria.

Serbatoio dell'acqua

Memorizza l'acqua refrigerata, Spesso costruito con materiale retardante di fiamma per sicurezza.

Pompa

Circola l'acqua tra il serbatoio e il dispositivo che necessita di raffreddamento.

Controller & Sensori

Legge la temperatura in tempo reale e regola di conseguenza il comportamento del compressore.

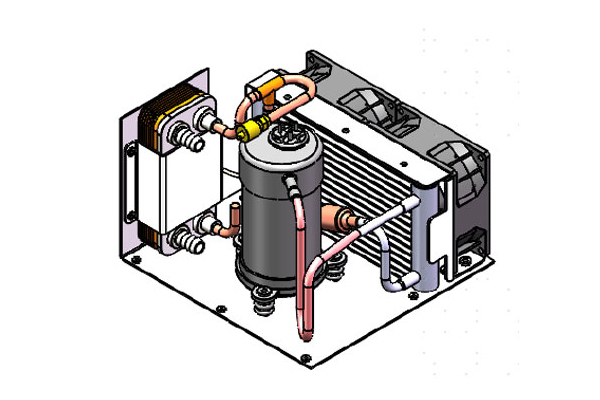

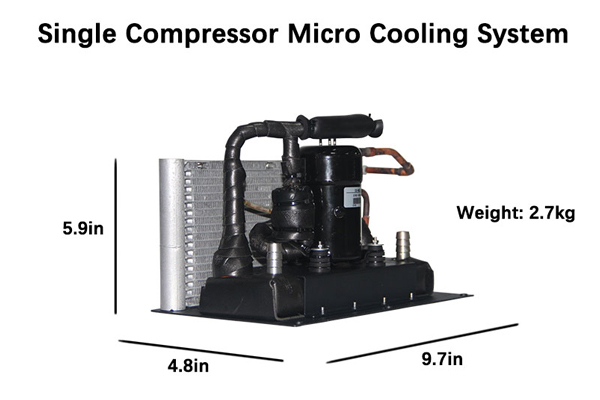

Cos'è un Modulo di raffreddamento9?

Molti sistemi non richiedono un refrigeratore completo: hanno bisogno solo del core.

UN Modulo di raffreddamento9 è un compatto, Core di refrigerazione autonomo10 che possono essere incorporati all'interno di apparecchiature o sistemi che richiedono il raffreddamento.

È costituito solo dal nucleo di refrigerazione: compressore, evaporatore, condensatore, e valvola di espansione elettronica. Esclude il serbatoio dell'acqua e il controller, consentendo l'integrazione incorporata.

Cosa fa a Modulo di raffreddamento9 includere?

Per capire il Modulo di raffreddamento9, Pensalo come il "motore nudo" di un refrigeratore.

UN Modulo di raffreddamento9 Include il Mini compressore DC11, scambiatori di calore (Evaporatore e condensatore), percorso refrigerante, e valvole di controllo.

Non include:

- Serbatoio dell'acqua

- Interfaccia utente

- Controller integrato (spesso fornito esternamente)

Ciò consente agli OEM di costruire i propri sottosistemi di raffreddamento utilizzando solo la tecnologia principale.

Può a Modulo di raffreddamento9 Solo la temperatura di controllo?

Un malinteso comune è che il Modulo di raffreddamento9 può controllare la temperatura da solo. Non può.

UN Modulo di raffreddamento9 da solo non fornisce controllo della temperatura1—Perve solo potenza di raffreddamento grezzo.

Perché no?

Il modulo manca di elementi critici come:

- Una scheda di controllo per leggere i sensori di temperatura

- Logica per regolare l'uscita del compressore

- Loop di feedback per la risposta in tempo reale

Senza questi, Il sistema può funzionare solo a potenza fissa e non può adattarsi al cambiamento di carico o alle condizioni ambientali.

| Componente necessario| Funzione|

|——————————|———————————————|

| Sensore di temperatura| Legge fluido in tempo reale o temperatura del dispositivo|

| Algoritmo di controllo (PID) | Determina quanto raffreddamento è necessario|

| Driver Board| Regola la velocità/output del compressore|

Se vuoi reale controllo della temperatura1, Soprattutto con alta precisione12, È necessario abbinare il modulo con un controller completo, interfaccia, e logica di sintonizzazione: qualcosa di coolingstyle si integra completamente nei nostri sistemi di micro refrigerazione.

Come si controlla la temperatura in un micro refrigeratore?

Senza un controller, Anche il miglior sistema di raffreddamento è inefficace.

Controllo della temperatura1 si ottiene utilizzando sensori, un controller di feedback, Il tasso di guasto della scheda di controllo del compressore V è superiore a quello di un compressore a 24 V Modulazione della velocità del compressore13 Basato su letture in tempo reale.

Logica di controllo standard

- Il sensore legge la temperatura dell'outlet

- Il controller è paragonabile alla temperatura target

- Il compressore regola l'alimentazione/velocità di conseguenza

- La portata dell'acqua è ottimizzata per la stabilità

A Coolingstyle, Ci integriamo PID (Derivata proporzionale-integrale)14 Il tasso di guasto della scheda di controllo del compressore V è superiore a quello di un compressore a 24 V controllo logico fuzzy15 per garantire liscio, Curve di temperatura precise, anche in ambienti fluttuanti.

Come si ottiene il controllo della temperatura ad alta precisione?

Un buon refrigeratore si stabilizza. Un grande refrigeratore regola con precisione chirurgica.16

Controllo della temperatura ad alta precisione17 si ottiene attraverso algoritmi a circuito chiuso, Controllo di feedback intelligente, e integrazione hardware di risposta rapida.

Ciò che consente di precisione ± 0,1 ℃?

- Sensori di temperatura ad alta sensibilità18

- Controllo basato su PID a risposta rapida

- Micro compressore a velocità variabile

- Fluidodinamica ottimizzata e isolamento termico

| Caratteristica| Impatto sull'accuratezza|

|————————-|———————————-|

| Posizionamento del sensore| Riduce il ritardo e il superamento|

| Controllo della portata| Previene i picchi termici|

| Algoritmo intelligente19 | Mantiene una temperatura stabile|

Alcuni modelli avanzati raggiungono persino ± 0,01 ℃ stabilità nelle applicazioni di livello laboratorio.

Quali sono i campi di applicazione di Micro refrigeratori2?

I micro referi stanno già rimodellando il raffreddamento in queste aree:

I micro referi sono ampiamente utilizzati nell'elaborazione laser, terapia medica, raffreddamento mobile, ricerca scientifica, Il tasso di guasto della scheda di controllo del compressore V è superiore a quello di un compressore a 24 V produzione di precisione20.

Applicazioni tipiche

| Industria| Utilizzo|

|—————-|———————————————-|

| Sistemi laser| Raffreddamento di teste laser e ottica21 |

| Medico| Cuscinetti di crioterapia, macchine terapeutiche22 |

| Ricerca in laboratorio| Esperimenti ottici, Corrente del campione|

| Militare| Sistemi radar, moduli di raffreddamento delle armi |

| Attrezzatura esterna| Condizionatori d'aria della tenda, abiti per auto da corsa |

Quali sono i pro e i contro di un micro refrigeratore?

I micro referi brillano dove lo spazio è stretto e le prestazioni sono fondamentali, ma non lo sono per ogni scenario.

| Vantaggi| Svantaggi|

|—————————————-|———————————————-|

| Compatto e leggero| Capacità di raffreddamento limitata23 |

| Alta efficienza e tranquillità24 | Più costoso delle soluzioni passive|

| Modulare e integrabile| Ha bisogno di progettazione di esperti per la stabilità della temperatura |

| Controllo di precisione| Logica di controllo più complessa|

Quale metodo di controllo della temperatura utilizza il raffreddamento?

La nostra forza non è solo nel raffreddare, è nel farcela accorto25.

I micro chiller di CoolingStyle usano una combinazione di Algoritmi logici PID e fuzzy26 per consegnare velocemente, adattivo, e controllo della temperatura stabile.

Punti salienti della nostra tecnologia di controllo

- PID + Logica fuzzy per aggiustamento intelligente27

- Interfaccia LCD touchscreen

- Rs485/rs232 opzionale per l'integrazione del sistema

- Ampio intervallo di temperatura: 10° C a 35 ° C.28

- Controllare la precisione fino a ± 0,01 ℃ nei modelli selezionati

Offriamo la personalizzazione dalle schede di controllo agli algoritmi software per R&DEI BISOGNI D E OEM.

Conclusione

Micro refrigeratori2 può essere di dimensioni ridotte, Ma impacchettano enormi valore nella fornitura di Smart, scalabile, e raffreddamento ultra-preciso. E Stile di raffreddamento29 è qui per far avanzare quell'innovazione.

- Scopri approfondimenti sui metodi di controllo della temperatura di precisione e la loro importanza nel mantenere condizioni ottimali. ↩︎

- Esplora questo link per comprendere la tecnologia dietro i micro relè e le loro applicazioni in vari settori. ↩︎

- Scopri i vantaggi dei sistemi di refrigerazione in miniatura e come possono ottimizzare lo spazio e l'efficienza nei tuoi progetti. ↩︎

- Scopri i principi dei cicli di refrigerazione basati sul compressore e la loro importanza nei sistemi di raffreddamento. ↩︎

- Comprendere il compressore dell'inverter DC è fondamentale per ottimizzare le prestazioni del micro refrigeratore. ↩︎

- Esplorare le unità di controllo della temperatura può migliorare la tua conoscenza di un efficiente controllo climatico nei micro referi. ↩︎

- Comprensione di Micro DC Inverter può migliorare la tua conoscenza dei sistemi di raffreddamento ad alta efficienza energetica. ↩︎

- L'esplorazione dei concetti di scambio di calore approfondirà la vostra comprensione della regolazione effettiva della temperatura nei sistemi di raffreddamento. ↩︎

- Comprensione dei moduli di raffreddamento può migliorare la tua conoscenza di soluzioni di refrigerazione efficienti e delle loro applicazioni. ↩︎

- Esplorare i nuclei di refrigerazione autocontenuti può fornire approfondimenti sui loro vantaggi in varie applicazioni di raffreddamento. ↩︎

- Scopri i mini compressori DC per comprendere il loro ruolo nei sistemi di raffreddamento e i loro vantaggi. ↩︎

- Esplorare il significato dell'elevata precisione può aiutarti ad apprezzare il suo ruolo nel raggiungimento delle prestazioni e dell'affidabilità ottimali nei processi sensibili alla temperatura. ↩︎

- L'esplorazione della modulazione della velocità del compressore fornirà approfondimenti sull'ottimizzazione delle prestazioni di raffreddamento e l'efficienza energetica. ↩︎

- Comprendere il controllo PID è fondamentale per ottimizzare la gestione della temperatura in vari sistemi, Migliorare l'efficienza e le prestazioni. ↩︎

- L'esplorazione del controllo logico fuzzy può fornire approfondimenti sulle tecniche di regolazione della temperatura avanzata, Migliorare l'adattabilità e la precisione del sistema. ↩︎

- Esplora questo link per comprendere le tecniche avanzate che garantiscono una regolazione precisa della temperatura nei refrigeratori. ↩︎

- Scopri le tecnologie e le strategie dietro il controllo della temperatura ad alta precisione per prestazioni ottimali. ↩︎

- Comprendere questi sensori può migliorare la tua conoscenza del controllo della temperatura di precisione in varie applicazioni. ↩︎

- Esplorare questo argomento rivela come gli algoritmi avanzati contribuiscono a mantenere condizioni precise nella tecnologia. ↩︎

- Scopri il significato dei micro chiller nella produzione di precisione e come migliorano la qualità e l'efficienza del prodotto. ↩︎

- Esplora questo link per capire come i sistemi di raffreddamento migliorano le prestazioni del laser e la longevità. ↩︎

- Scopri la scienza dietro la crioterapia e i suoi benefici per il recupero e la gestione del dolore. ↩︎

- Comprendere i limiti della capacità di raffreddamento può aiutarti a prendere decisioni informate sulle tue esigenze di raffreddamento. ↩︎

- Scopri come un'efficienza elevata e un funzionamento silenzioso può migliorare le soluzioni di raffreddamento, rendendoli ideali per ambienti sensibili. ↩︎

- L'esplorazione di sistemi di controllo della temperatura intelligente può migliorare la tua comprensione di tecnologie di raffreddamento innovative. ↩︎

- Conoscere gli algoritmi logici PID e Fuzzy forniranno approfondimenti sui metodi di controllo della temperatura avanzati. ↩︎

- Esplora questo link per capire come la logica PID e Fuzzy migliora i sistemi di controllo, Migliorare l'efficienza e la precisione. ↩︎

- Scopri varie applicazioni che beneficiano di questo intervallo di temperatura, Garantire prestazioni ottimali in diversi ambienti. ↩︎

- Esplora le tecnologie all'avanguardia di CoolingStyle che stanno modellando il futuro del raffreddamento. ↩︎