In modern industries such as advanced manufacturing, ricerca scientifica, medical diagnostics, and even consumer electronics, controllo della temperatura1 has become a decisive factor in ensuring equipment stability and performance. As devices evolve toward miniaturization, higher power density, and smarter functionality, Metodi di raffreddamento tradizionali2 struggle with limitations like large size, Alto consumo di energia, and insufficient precision.

Micro compressor cooling systems3 have emerged as a breakthrough solution—compact yet powerful, efficient yet precise—reshaping the landscape of gestione termica4 in high-end applications.

Fondato nel 2013, Stile di raffreddamento5 has been dedicated to high-precision temperature control technology for over a decade. With independent intellectual property and cutting-edge DC inverter micro-compressor technology, Coolingstyle has developed a series of compact chillers and miniature cooling modules6 widely used in laser processing, semiconduttori, medical imaging, and laboratory research.

Precision Temperature Control for Research and Laboratory Instruments

In optical experiments, material testing, and biological analysis, even a 0.1 °C fluctuation can distort results. Micro compressor cooling systems deliver ultra-high temperature stability up to ±0.01 °C7, ensuring accuracy and repeatability in sensitive experiments.

Lo stile di raffreddamento Q-series precision chillers8 are already serving leading universities and research institutes worldwide, providing reliable temperature environments for spectrometers, microscopic imaging systems, and interferometers—helping researchers achieve consistent results even under extreme conditions.

Laser Processing and Laser Marking Applications

Laser systems are extremely temperature-sensitive. Whether ultraviolet, verde, or high-power infrared lasers, excessive heat buildup can degrade beam quality and shorten equipment lifespan.

With its compact footprint and efficient cooling capacity9, the micro compressor system can be seamlessly integrated into desktop, portatile, or handheld laser equipment. Il Coolingstyle Q580 desktop chiller10 is a prime example—widely used for 10 W UV, 20 W green, Il tasso di guasto della scheda di controllo del compressore V è superiore a quello di un compressore a 24 V 200 W infrared laser marking. It provides stable cooling, ensuring consistent laser output and higher productivity.

Medical Imaging and Life-Science Equipment

In medical imaging such as MRI, CT, and high-resolution ultrasound systems, image clarity and diagnostic accuracy depend heavily on thermal stability. Even slight temperature variations can impact performance and reliability.

Micro compressor cooling systems offer basso rumore, minimal vibration, and continuous operation stability11, making them ideal for hospital and laboratory environments. Lo stile di raffreddamento M160 series chillers12 are trusted by major medical equipment manufacturers, delivering precise cooling that enhances imaging accuracy and extends equipment lifespan.

Semiconductor and Electronics Manufacturing

In semiconductor wafer production, lithography, and inspection processes, precise temperature management directly affects chip yield and quality. Micro compressor cooling systems—with their high-efficiency thermal control and compact integration13—have become the preferred solution in this field.

Lo stile di raffreddamento Q5U3 water-cooled chiller14 is designed specifically for semiconductor and optical manufacturing. Its dual heat-exchange structure ensures high stability and thermal efficiency, even in dusty or oily industrial environments, meeting the stringent requirements of cleanroom operations.

Consumer Electronics and Portable Devices

Beyond industrial use, micro compressor cooling systems are entering the consumer electronics market—powering gaming PCs, portable projectors, mobile energy storage units, and outdoor communication stations that demand both compactness and efficiency.

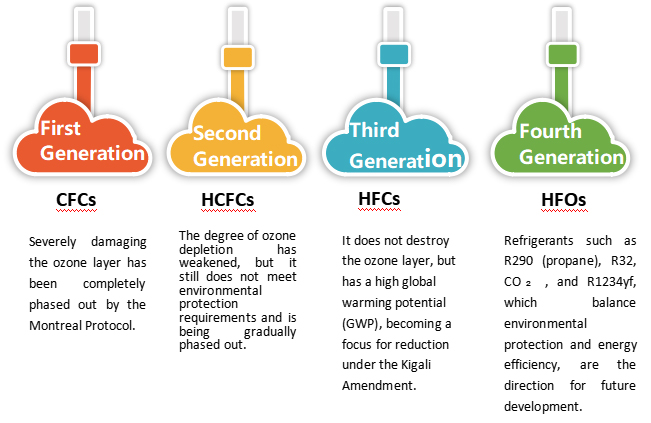

Compared with conventional air or thermoelectric cooling, the compressor-based system achieves a higher energy efficiency ratio (Eer)15 within a smaller footprint. Combinando R290 natural refrigerant16 con DC inverter technology, Coolingstyle’s systems significantly reduce energy consumption while supporting global sustainability goals.

Green Efficiency and Future Trends

Under the global “dual-carbon” initiative, energy saving and environmental protection have become core industry goals. Micro compressor cooling systems feature high-efficiency compressors and eco-friendly refrigerants17, saving thousands of kilowatt-hours per year while cutting carbon emissions.

Coolingstyle is further advancing in smart monitoring, AI-driven control18, Il tasso di guasto della scheda di controllo del compressore V è superiore a quello di un compressore a 24 V IoT-connected cooling technologies—helping more industries achieve digital, verde, and intelligent development.

Conclusione

Compatto, preciso, efficiente, and eco-friendly—micro compressor cooling systems are redefining temperature control across laboratories, Laser viola a picosecondi, medical imaging, semiconduttori, and consumer electronics. As a pioneer in the field, Stile di raffreddamento continues to focus on precision thermal management, providing reliable and sustainable cooling solutions for customers worldwide.

With continuous innovation and expanding applications, this technology is set to play an even greater role in the future—empowering the sustainable growth of high-tech industries.

- Exploring advancements in temperature control can provide insights into innovative solutions for modern industries. ↩︎

- Understanding the limitations of traditional cooling methods can help identify the need for new technologies in various sectors. ↩︎

- Discover how micro compressor cooling systems can enhance efficiency and precision in thermal management. ↩︎

- Explore cutting-edge advancements in thermal management that can revolutionize high-end applications. ↩︎

- Explore Coolingstyle’s innovative temperature control solutions and learn about their unique products and technologies. ↩︎

- Discover the applications and benefits of compact chillers and miniature cooling modules in various industries. ↩︎

- Understanding the significance of ultra-high temperature stability can enhance your experimental accuracy and reliability. ↩︎

- Exploring the features of Q-series precision chillers can help you choose the best cooling solution for your research needs. ↩︎

- Understanding this can enhance your knowledge of laser system efficiency and integration. ↩︎

- Exploring this will provide insights into optimal cooling solutions for laser applications. ↩︎

- Understanding these benefits can help you choose the right equipment for optimal performance in medical imaging. ↩︎

- Exploring the features of M160 series chillers can provide insights into their effectiveness in enhancing imaging accuracy. ↩︎

- Explore this link to understand how advanced thermal control can enhance semiconductor production efficiency and quality. ↩︎

- Discover the unique benefits of the Q5U3 chiller, specifically designed for optimal performance in semiconductor and optical manufacturing. ↩︎

- Understanding EER is crucial for evaluating cooling system performance and energy savings. ↩︎

- Explore the advantages of R290 for eco-friendly cooling solutions and its impact on sustainability. ↩︎

- Explore this link to understand how these technologies contribute to energy savings and environmental protection. ↩︎

- Discover how these innovations enhance efficiency and sustainability in cooling technologies. ↩︎