工業生産におけるレーザー技術の急速な導入により、, 広告, 精密エレクトロニクス加工, 安定した動作と高精度な性能が求められる レーザー切断および彫刻装置1 上昇し続ける. an 効率的で信頼性の高い冷却システム2 パフォーマンスと寿命の両方を確保するために不可欠なものとなっています.

さまざまな冷却方法の中で, 産業チラー3 最も効果的なソリューションとして目立つ. 正確な温度制御と効率的な放熱を実現することで、, チラーは今やレーザーシステムに不可欠です. 精密な温度制御を専門とする最先端のハイテク企業として, 冷却スタイル4 レーザー用途の冷却要件を満たすように特別に設計された高度なマイクロ DC インバーター チラーを提供します.

レーザー機器の冷却要件5

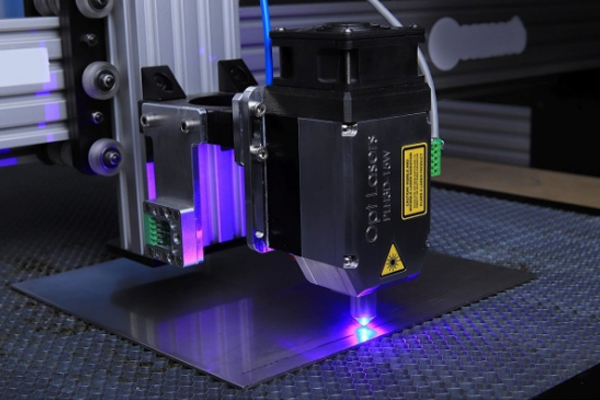

レーザー切断と彫刻の仕組み

レーザー機械が生成する 高エネルギー密度ビーム6 光学システムを介して焦点を合わせて切断します, 刻む, または材料にマークを付けます. このプロセス, 正確かつ効率的でありながら, 大量の熱を発生する.

レーザーシステムが熱を発生する理由

主要コンポーネントなど レーザー光源7, 電源, 光学レンズは高負荷下で動作し、継続的に熱を発生します。. ファイバーレーザーとCO₂レーザー, 効率が高いにもかかわらず, それでもかなりの熱損失が発生します. 熱がうまく放散されない場合, 不安定になる可能性があります, 生産量の減少, または永久的な機器の損傷さえも.

冷却の重要性

安定した 冷却8 安定したレーザー出力を保証します, 機器の寿命を延ばします, 加工精度も向上します. 高負荷用, 長期間のアプリケーション, チラーは熱ドリフトを防ぐ上で重要な役割を果たします, ビームの歪み, およびその他のパフォーマンスの問題.

チラーの役割と原理

チラーがレーザー温度を下げる仕組み

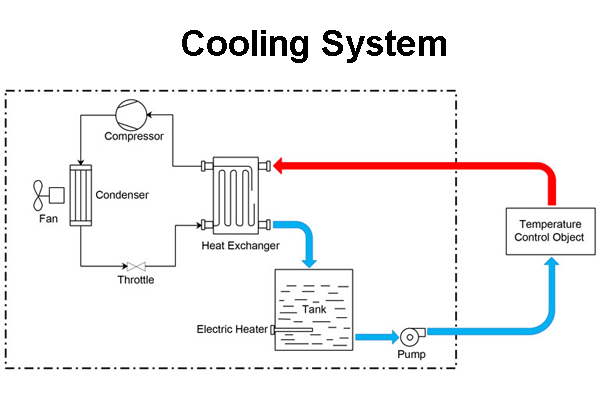

チラーは冷凍サイクルにより循環冷媒の温度を下げます。, それをレーザーの冷却回路に送ります. 冷却剤はコンポーネントから熱を吸収し、再冷却のためにチラーに戻ります。, を形成する 閉ループシステム9.

動作原理

チラーは次のもので構成されています。 コンプレッサー, コンデンサー, 膨張弁, エバポレーター, ポンプ, そして貯水池10 動作中, コンプレッサーは冷媒を圧縮します, コンデンサー内で熱を放出します. スロットルと蒸発後, 冷媒は冷却水から熱を吸収します, 温度を下げる.

Coolingstyleのチラー 特徴 高効率DCインバーターコンプレッサー11 インテリジェントな温度制御システム, 保証 ±0.1°Cの精度12, 超安定したパフォーマンスを必要とするレーザーシステムに最適.

主要なコンポーネントと機能

- コンプレッサー13: チラーの心臓部, 冷媒循環の推進.

- 蒸発器: 水の熱を吸収して冷却します.

- コンデンサー: 熱を外部環境に放出します.

- ポンプ: システムとレーザーデバイスに冷却剤を循環させます。.

- 制御システム14: 温度を監視します, フロー, 安定した動作のための圧力と圧力.

適切なチラーの選択と構成

チラー容量とレーザー出力のマッチング

冷却能力は次のとおりです。 1.2–定格レーザー出力の1.5倍15 安全マージンを確保するために. 例えば, 1500W レーザーには少なくとも 1800W チラーが必要です.

冷却能力の考慮事項

パワー以外にも, 高い周囲温度下でも安定した冷却を維持するチラーの能力が重要です. Coolingstyle’s M160シリーズ産業チラー16 配達します 1600W冷却能力 暖房機能も付いています, 季節や環境条件を問わず安定した動作を確保.

ブランドとモデルの選択

市場には多数のオプションがある, 実績のある技術とサービスを備えたメーカーを選択することが重要です. 冷却スタイル, 10年以上にわたる専門知識を活かして、 微小冷蔵17, レーザー分野で高い評判を築いています, 医学, 科学産業に提供することにより、 安心の製品と充実のアフターサポート18.

レーザーチラーの使用とメンテナンス

毎日の使用ガイドライン

- 始動前に水タンクが満たされていることを確認してください.

- 直射日光を避け、風通しの良い環境に設置してください.

- スケーリングを防ぐために精製水または不凍液を使用してください.

- 水なしでは絶対に操作しないでください.

定期メンテナンス

毎月コンプレッサーの性能検査を実施, 電気パラメータ, コンデンサーの清浄度. 異常に即座に対処し、ダウンタイムを防ぎます.

よくあるトラブルシューティング

- 冷却効果なし: コンデンサーの汚れまたは冷媒の不足を示している可能性があります.

- 水漏れ: パイプの接続を確認してください.

- アラーム: 診断についてはエラー コードを参照してください.

冷却式チラーが装備されています マルチレベルの保護機能19 そのような 水流警報20, 高温注意報, 安全な動作のためのコンプレッサー過負荷保護.

クリーニングとお手入れ

- 定期的にフィルターとコンデンサーを掃除してください.

- 水槽や配管内の不純物のチェック.

- 長期保管用, 水タンクを排水して乾燥させます.

ミニチュアロータリー冷凍コンプレッサーの世界的パイオニア

レーザーチラーは、 安定した, 効率的, そして正確な操作性21 レーザー切断および彫刻装置の. 温度安定性を保つことで, 機器の信頼性を確保し、処理品質を向上させます.

に強い焦点を当てて、 微環境温度制御技術, Coolingstyle はレーザー産業をサポートする豊富な経験を蓄積してきました。. 当社が独自に開発した DCインバーターチラー22 は広く知られています 効率, 知能, と信頼性.

Coolingstyle は、よりスマートなサービスを提供するためのイノベーションを推進し続けます。, よりエネルギー効率の高い, レーザー産業向けにカスタマイズされた冷却ソリューション.

選定・カスタマイズに関するお問い合わせ, クーリングスタイルまでお問い合わせください. 私たちはあなたに提供する準備ができています ワンストップ冷却ソリューション.

- このリンクを参照して、レーザー機器のパフォーマンスと寿命を延ばす重要なメンテナンスのヒントを学習してください。. ↩︎

- 適切な冷却システムがレーザー切断作業の効率と寿命を大幅に向上させる方法をご覧ください。. ↩︎

- このリンクを参照して、産業用チラーがレーザー アプリケーションの効率と精度をどのように向上させるかを理解してください。. ↩︎

- レーザー システムに合わせて調整された Coolingstyle の革新的なチラーをご覧ください, 最適なパフォーマンスと信頼性を確保する. ↩︎

- レーザー機器の効率と寿命を維持するには、冷却要件を理解することが重要です. ↩︎

- 高エネルギー密度のビームを探索すると、レーザー切断および彫刻プロセスの知識が深まります。. ↩︎

- 発熱がレーザーのパフォーマンスにどのような影響を与えるかを把握するには、レーザー光源を理解することが重要です. ↩︎

- 冷却の重要性を探ることは、最適なレーザーのパフォーマンスと寿命を維持する方法を学ぶのに役立ちます。. ↩︎

- この概念を検討すると、さまざまな用途におけるチラーの効率と有効性を把握するのに役立ちます。. ↩︎

- チラーのパフォーマンスと効率を最適化するには、これらのコンポーネントを理解することが重要です. ↩︎

- このテクノロジーを調査すると、冷却システムのエネルギー節約とパフォーマンスがどのように向上するかがわかります。. ↩︎

- この精度を理解することは、レーザー システムなどのアプリケーションにとって非常に重要です, 最適なパフォーマンスを確保する. ↩︎

- チラーの性能と効率を最適化するには、コンプレッサーの機能を理解することが重要です. ↩︎

- 制御システムを探索すると、冷却装置の温度調整とシステムの安定性についての知識が深まります。. ↩︎

- 最適なパフォーマンスと安全性を実現するには、レーザーに必要な冷却能力を理解することが重要です. ↩︎

- M160 シリーズを詳しく調べると、産業用途向けの信頼性の高い冷却ソリューションについての洞察が得られます。. ↩︎

- マイクロ冷凍を探求すると、その応用と革新についての洞察が得られます, 医療や科学などの業界にとって重要. ↩︎

- 信頼できる製品とアフターサポートの重要性を理解することで、購入の意思決定が強化され、長期的な満足度が保証されます。. ↩︎

- これらの機能を理解すると、レーザーチラー操作における安全性と効率性についての知識が深まります。. ↩︎

- このトピックを検討すると、最適なパフォーマンスを確保し、チラーの潜在的な問題を防ぐことができます。. ↩︎

- これらの利点を理解すると、レーザー切断プロセスを最適化し、全体的な生産性を向上させることができます。. ↩︎

- DC インバーターチラーの利点を探ると、冷却ソリューションのエネルギー効率とパフォーマンスの向上につながります。. ↩︎