先進的な製造業において, 科学研究, および医療用途, 機器の性能と信頼性は安定性に大きく依存します, 正確な温度制御. 半導体製造であろうと, 高出力レーザー加工, または継続的な医療画像処理, わずかな温度変動でも精度が損なわれる可能性があります, 機器の寿命を縮める, 運用上のリスクが増大する.

Coolingstyle は次のことに取り組んできました。 精密な熱管理1 10年以上にわたって, 信頼できるものを提供する, エネルギー効率の高い, 世界中のハイテク産業の厳しい要求を満たす完全にカスタマイズされた冷却ソリューション.

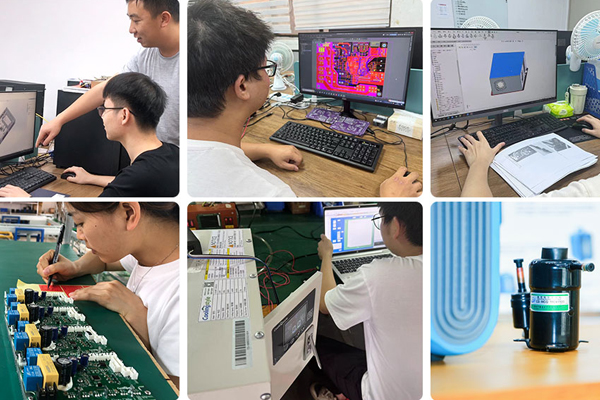

R&コアコンピタンスとしてのD

ハイエンドアプリケーション向け, 冷却システムは基本的な温度低下を超えたものでなければなりません. 彼らは優れている必要があります 正確さ, 応答性, 動作の安定性2. Coolingstyle の長期的な競争力は、研究開発への継続的な投資によってもたらされます。:

学際的なイノベーション

マイクロコンプレッサー冷却の統合, DCインバータ制御, PCM蓄熱, IoTベースの監視, Coolingstyle は、完全に社内で設計されたエンドツーエンドのソリューションを提供します.

独自の制御アルゴリズムと高応答可変速コンプレッサーにより±0.01℃以内の安定性を実現, 複雑な負荷条件下でも.

極限状態のテスト

すべての製品は熱の厳密なシミュレーションを受けています, 湿度, ほこり, 世界的な動作環境での耐久性を保証するため、専用の環境ラボで電磁干渉を防止します。.

複数の高精度セクターにサービスを提供

Coolingstyle のソリューションは、温度管理がミッションクリティカルである業界で信頼されています:

1. 半導体 & マイクロエレクトロニクス

エッチングおよびリソグラフィーのプロセスでは絶対的な安定性が求められます。0.1°C の偏差でも回路パターンの精度に影響を与える可能性があります。. 当社の低脈動, 高速応答冷却システムにより、中断のない高負荷動作が保証されます。.

レーザー切断, 溶接, 彫刻すると激しい熱が発生し、ビームの品質が低下する可能性があります. Coolingstyle のレーザーチラーは、インテリジェント DC インバーター技術を使用して、急速冷却と最適化されたエネルギー効率の両方を実現します。.

MRI, CT, 放射線治療装置は、振動や騒音を最小限に抑えた安定した冷却を必要とします。. 当社の医療グレードのチラーは、患者の快適性を向上させながら機器のパフォーマンスを保証します.

4. 科学的 & 実験室での応用

質量分析計や電子顕微鏡などの機器は、一貫した温度安定性に依存します。. Coolingstyle のラボグレードのシステムが稼働 24/7 遠隔監視あり, データの再現性と信頼性を確保する.

独自の要件に合わせたカスタマイズされたソリューション

Coolingstyle は、設計およびプロトタイプの検証から量産に至るまで、完全にカスタマイズされた開発プロセスを提供し、各システムが正確な運用要件および環境要件を満たしていることを保証します。:

- コンパクトまたは埋め込み構造 スペースに制約のある環境向け

- パフォーマンスマッチング 特定の熱負荷プロファイルに基づく

- OEM/ODMのカスタマイズ7 ブランディングのための, インタフェース, および業界標準

当社のカスタマイズ機能により、クライアントは高い技術パフォーマンスを維持しながら市場投入までの時間を短縮できます。.

持続可能性とエネルギー効率

Coolingstyle は製品開発のあらゆる段階に持続可能性を組み込んでいます:

- オンデマンド冷却 DCインバーターコンプレッサーと電子膨張弁を搭載し、エネルギーの無駄を最小限に抑えます。

グローバルサービスネットワーク

ものづくりとRとは&深センのD施設, 紹興, そして東莞, と一緒に 国際的な販売およびサービスネットワーク10, Coolingstyle は世界中の顧客に確実なサービスを提供します 迅速な技術サポート11, リモート診断, 機器のライフサイクル全体にわたるスペアパーツの供給.

ミニチュアロータリー冷凍コンプレッサーの世界的パイオニア

の 精密冷却12, R&D はパフォーマンスの上限を決定します. 独自のイノベーションを組み合わせることで, 業界を超えた専門知識, 高度なカスタマイズ機能, Coolingstyle で安定した性能を実現, 効率的, そして環境に配慮した 熱管理ソリューション13 世界で最も要求の厳しい業界向け. 今後, 私たちは精度の限界を押し広げ続けます, 効率, 冷却技術のインテリジェンスとインテリジェンスにより、お客様が製造業でより優れたパフォーマンスを達成できるようにします。, 研究, とヘルスケア.

- このリンクを参照して、高精度の熱管理がハイテク産業の機器のパフォーマンスと信頼性をどのように向上させるかを理解してください。. ↩︎

- これらの利点を理解すると、ハイエンドの冷却ソリューションとさまざまなアプリケーションにおけるその重要性についての知識が深まります。. ↩︎

- このトピックを検討すると、高度な冷却技術とその効率と信頼性への影響についての洞察が得られます。. ↩︎

- このリンクを参照して、レーザー加工の効率と品質を向上させる高度な冷却技術を発見してください。. ↩︎

- 革新的な冷却ソリューションがどのように医用画像装置の性能と信頼性を向上させるかを学びましょう. ↩︎

- 運用における接続性とパフォーマンスを向上させるための制御システム統合の利点について学びます. ↩︎

- このリンクを参照して、OEM/ODM カスタマイズがどのようにブランドを強化し、効果的に業界標準を満たすことができるかを理解してください。. ↩︎

- R290 のような環境に優しい冷媒が環境への影響をどのように大幅に削減できるかを理解するには、このリンクを参照してください。. ↩︎

- IoT の予知保全がどのように製品のライフサイクルとエネルギー効率を向上させることができるかをご覧ください, 持続可能な実践につながる. ↩︎

- この概念を理解すると、グローバル ロジスティクスと顧客サポート戦略についての知識が深まります。. ↩︎

- このトピックを検討すると、タイムリーなサポートがいかに顧客ロイヤルティと業務効率を大幅に向上させることができるかがわかります。. ↩︎

- このリンクを参照して、効率とパフォーマンスを向上させる精密冷却の最先端のイノベーションを発見してください。. ↩︎

- このリソースは、高性能産業向けにカスタマイズされた効果的な熱管理ソリューションに関する洞察を提供します。. ↩︎