スマート製造と新しい生産性モデルが世界の産業を再構築するにつれて, レーザー技術1 産業高度化の原動力となっている. 新エネルギー自動車部品や半導体製造から医療用画像や精密光学まで, レーザーは生産効率と精度を再定義します. この急速な拡大に伴い、, D印刷冷却産業, NS 安定した正確な温度制御が求められる2 一貫したレーザーパフォーマンスと長期的なシステム信頼性を確保するために、ますます重要になっています.

このような背景に対して, NS レーザーチラー3 熱安定性の維持に重要な役割を果たします. 小型・高精度冷却システムのトップメーカーとして, クーリングスタイルテクノロジー株式会社, 株式会社.4 インテリジェントな開発に重点を置いています, エネルギー効率の高い, レーザー機器が最高の精度と信頼性で動作できるようにする環境に優しい冷却ソリューション.

中国のレーザー産業の進化

中国のレーザー産業は質の高い成長段階に入った, レーザー光源や光学システムから完全な機器の統合まで、サプライチェーン全体をカバー. 急速な進歩 超高速およびファイバーレーザー技術5 国内の生産能力を大幅に強化し、新エネルギーなどの分野への用途を拡大しました。, 半導体, 医療機器, および家庭用電化製品.

しかし, レーザーシステムは高出力動作中にかなりの熱を発生します. 効果的な冷却ができないと, パフォーマンスの低下, 電力の不安定性, あるいはコンポーネントが損傷する可能性もあります. したがって、, a 信頼性の高い正確な冷却システム6 単にサポートするだけではなく、出力の安定性を確保することが不可欠です, 寿命を延ばす, 設備投資を保護する.

市場の成長と温度安定性に対する需要の高まり

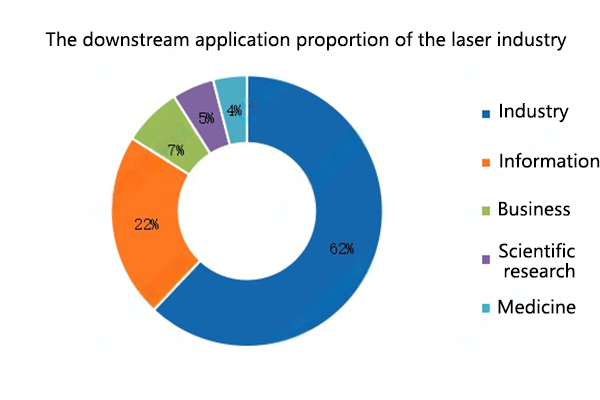

複数の業界レポートによると, NS 世界のレーザー市場7 を超えると予想される 米ドル 25 10億まで 2026, 中国は年間成長率を上回っている 10 %. この拡大は主に、高出力かつ高精度のレーザー システムの導入が急増していることによって推進されています。 EV製造, 3Cエレクトロニクス, 医療美学, および光通信.

こうした進化するニーズに応えるために, 冷却スタイル を立ち上げました Q420, Q5U3, および M160 シリーズ レーザー チラー, 独自の機能を備えた DCインバーターマイクロコンプレッサー技術8 ±0.01℃の温度精度を維持可能. これらのコンパクトで高性能なチラーはファイバーレーザーマーキングに広く使用されています, チップのパッケージング, ガラス微細加工, 要求の厳しい産業環境に継続的かつ安定した冷却性能を提供します。.

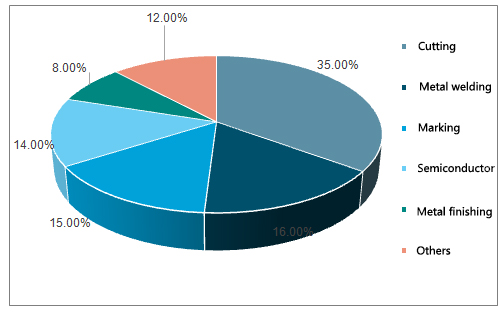

レーザー技術の応用分野の拡大

レーザー溶接9

EVのバッテリータブとケースの溶接, 高精度チラーはビームの安定性を維持し、一貫した溶接品質を確保します。.

レーザー切断とマーキング

デスクトップレーザーチラーは小型機器では標準となっています- 金属エンクロージャ用の中電力システム, 家電, および精密部品, 中断のない生産を可能にする.

半導体およびフォトニクス製造10

ウェーハダイシングやガラス穴あけなどの超高速レーザーアプリケーションには、迅速かつ正確な温度応答が必要です. 冷却スタイルのチラーは動的熱補償を提供し、優れた光学的安定性を実現します。.

科学研究と医療利用

光学イメージングにおいて, レーザー手術, そして光線力学療法, 低騒音と正確な温度制御により、安全で信頼性の高い動作が保証されます。.

インテリジェンスと持続可能性が未来を定義する

レーザー産業は次のような方向に進化しています。 より高い電力密度, 小さいサイズ, そしてより優れた知性11. AIとIoT技術の融合により, 温度管理は パッシブ冷却 に アクティブな予測管理12.

センサーフィードバックとデータモデリングを活用することで, 次世代チラーは熱負荷の変化を予測し、熱バランスを最適化するためにパフォーマンスを自動的に調整できます。.

冷却スタイル この変革の最前線に立ってきた. インテリジェントなレーザーチラーによるサポート 遠隔監視, 自動調整, と 早期警告診断. 装備 R290自然冷媒, 各ユニットは最大まで保存できます 3,000 年間の電力量 kWh, お客様がエネルギー効率と炭素削減の両方の目標を達成できるよう支援します.

精密冷却: レーザーパフォーマンスの基礎

レーザー加工では, ビームの安定性は精度と収量に直接影響します. たとえ 0.1 ℃偏差13 ビームドリフトを引き起こす可能性があります, 電力損失, またはシステムのシャットダウン. したがって, 精密な温度制御は単なる技術的な機能ではなく、生産性に影響を与える中心的な要素です, 製品の品質, そしてブランドの評判.

10年以上にわたる専門知識を活かして、 微環境冷凍14 と 高精度の熱管理, 冷却スタイル 先進的なサービスを提供し続ける, 信頼性のある, 世界中のレーザー用途向けの効率的な冷却ソリューション. 前進します, 同社は、レーザー業界をさらなる発展に向けて推進することに引き続き取り組んでいます。 知的, 持続可能な, 精度主導の未来.

- このリンクを参照して、製造プロセスを変革するレーザー技術の最先端のイノベーションを発見してください。. ↩︎

- 温度制御の重要性を理解すると、レーザーのパフォーマンスとシステムの信頼性についての知識が深まります。. ↩︎

- レーザー装置のパフォーマンスを最適化し、熱安定性を確保するには、レーザーチラーを理解することが重要です. ↩︎

- Coolingstyle の製品を調査すると、レーザー技術向けの高度な冷却ソリューションについての洞察が得られます。. ↩︎

- このリンクを参照して、これらのテクノロジーがどのように業界に革命を起こし、生産能力を向上させているかを理解してください。. ↩︎

- レーザーのパフォーマンスを維持し、機器の寿命を延ばす上での冷却システムの重要性を理解します。. ↩︎

- このリンクを参照して、世界のレーザー市場の傾向と予測を理解してください。, これは業界の洞察にとって非常に重要です. ↩︎

- このテクノロジーの仕組みと利点を理解する, 冷却システムの精度を維持するために不可欠. ↩︎

- このリンクを参照して、レーザー溶接がどのように EV バッテリー生産の効率と品質を向上させるかを理解してください。. ↩︎

- 革新的なアプリケーションのための半導体およびフォトニクス製造の進歩におけるレーザー技術の役割を発見します。. ↩︎

- レーザー技術の進歩により、さまざまなアプリケーションの効率とパフォーマンスがどのように向上するかを探ります。. ↩︎

- 大幅なエネルギー節約と効率化につながる、温度制御の革新的なアプローチについて学びます。. ↩︎

- 温度偏差の影響を理解すると、レーザー加工の精度と効率が向上します。. ↩︎

- 微環境冷凍を調査すると、さまざまな業界向けの高度な冷却ソリューションについての洞察が得られます. ↩︎