Lazer sistemleri daha yüksek güce ve daha hassas hassasiyete doğru geliştikçe, a reliable high-precision mini laser chiller has become an essential component to ensure consistent performance and system stability. Lazer kaynağınızı korumak ve ömrünü uzatmak için etkili bir soğutma çözümü arıyorsanız, bu kılavuz temel ilkeleri anlamanıza yardımcı olacaktır, key parameters, and best practices for selecting the right laser chiller.

What Is a High-Precision Mini Laser Chiller?

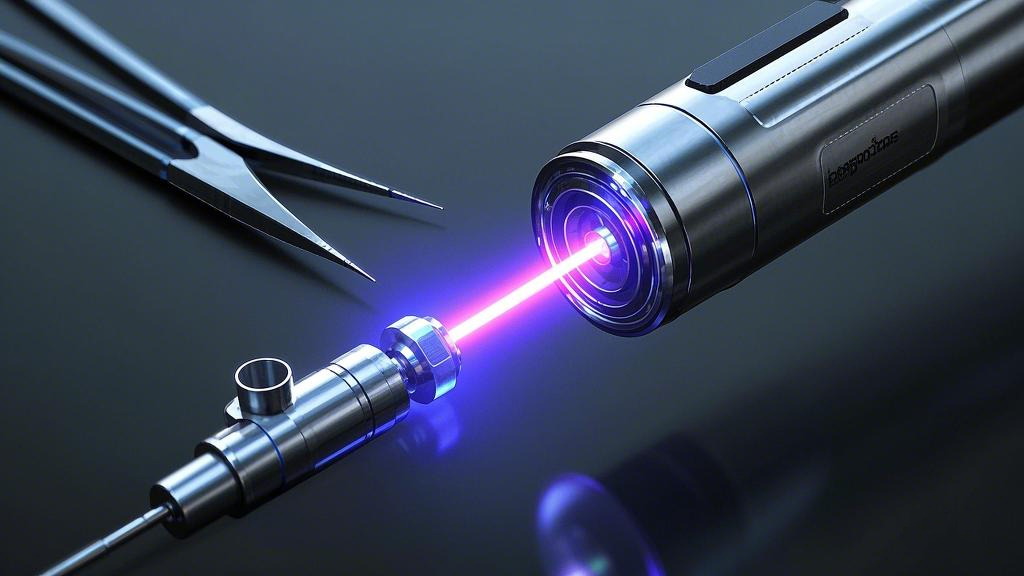

A high-precision mini laser chiller is a compact water cooling system designed specifically for stabilizing the temperature of laser equipment. Compared with traditional large chillers, mini chillers offer smaller size, faster response, and higher temperature control accuracy — often within ±0.1 °C. These systems are ideal for laser engraving, micromachining, işaret, and laboratory environments where space and precision are equally critical.

Key Parameters When Choosing a High-Precision Mini Laser Chiller

1. Sıcaklık Kontrol Doğruluğu

Temperature precision directly affects laser beam quality and operational stability. Leading models provide ±0.1 °C precision to maintain a constant cooling temperature for ultrafast or UV laser systems. A reliable chiller ensures consistent output and prevents thermal drift that can impact fine processing results.

2. Cooling Capacity and Flow Rate

The cooling power and water flow must match the heat output of your laser system. If the capacity is too low, the laser temperature will rise, leading to output instability and optical misalignment. Always check the rated cooling capacity (Watts'ta) and flow rate before purchasing.

3. Compact Size and Space Efficiency

“Mini” chillers are particularly suitable for small laboratories or workshops with limited installation space. Compact models often feature vertical layouts, built-in handles, or wheels for flexible mobility without sacrificing cooling performance.

4. Maintenance and Safety Features

A good mini laser chiller should include water-level monitoring, flow sensors, over-temperature alarms, and easily replaceable filters. These features ensure safe operation and minimize downtime during maintenance.

Typical Applications of High-Precision Mini Laser Chillers

High-precision mini laser chillers are widely used in the following applications:

- Laser Engraving and Marking Machines – Frequent operation with moderate laser power but high stability requirements.

- Micromachining Systems – Compact setups that demand highly stable temperature control.

- Scientific Research and Laboratory Use – Sensitive optical experiments that require minimal temperature fluctuation.

In these scenarios, temperature stability within ±0.1 °C can dramatically improve laser performance, ensuring accuracy, güvenilirlik, and long-term consistency.

Buying Tips and Recommended Brands

Before purchasing a high-precision mini laser chiller, aşağıdakileri göz önünde bulundurun:

- Confirm your laser’s required cooling capacity, sıcaklık aralığı, and flow rate with the manufacturer.

- Prioritize chillers with a temperature accuracy of ±0.5 °C or better.

- Choose units that are easy to maintain and equipped with alarm systems and water filters.

- Check the availability of after-sales service and spare parts to ensure long-term reliability.

Reputable brands such as Coolingstyle, S&A, and MSE Supplies provide compact laser chillers specifically designed for industrial and scientific laser systems. These models emphasize precision, kompaktlık, ve enerji verimliliği.

Maintenance Tips for Long-Term Stability

To keep your high-precision mini laser chiller operating efficiently, follow these maintenance tips:

- Use deionized or filtered water to prevent scale buildup and ensure optimal heat transfer.

- Clean filters and check water flow and levels regularly.

- Keep the cooling environment well-ventilated to avoid overheating.

- Address system alarms (temperature, water level, or flow rate) immediately to prevent damage.

Çözüm: Why Invest in a High-Precision Mini Laser Chiller?

In summary, a high-precision mini laser chiller offers a perfect balance between performance and compactness — providing stable cooling, hassas sıcaklık kontrolü, and enhanced laser system longevity. Whether for industrial marking, microfabrication, or laboratory applications, investing in a quality mini chiller ensures reliable, high-accuracy operation.

Take these two actions today:

- Evaluate your current laser cooling system: is it maintaining stable temperature without fluctuation?

- Compare available mini chiller models — focusing on precision, boyut, and reliability — to find the best match for your laser application.

Sıkça Sorulan Sorular (SSS)

1. Çeyrek: Why choose a mini laser chiller instead of a conventional large unit?

Mini chillers are optimized for smaller systems or spaces where precision and flexibility matter most. They provide equal or even higher control accuracy in a more compact design, ideal for high-precision laser equipment.

2. Çeyrek: Is ±0.1 °C temperature accuracy really necessary?

For high-end laser engraving or ultrafast systems, even slight temperature changes can alter beam stability or processing accuracy. Ocak ayı, ±0.1 °C precision is essential to ensure consistent laser output and repeatable results.