Liquid chiller cooling systems are transforming industrial operations by efficiently managing heat dissipation for machinery and environments. Whether for manufacturing facilities, hotels, restaurants, or industrial plants, liquid chillers offer a compact and reliable solution to control temperature and optimize performance.

This article dives into how liquid chillers work, their key factors for selection, and highlights Coolingstyle’s micro water chillers and rack-mounted chillers as top-notch options.

What is a Liquid Chiller?

A liquid chiller is a cooling system designed to reduce heat by circulating a cooled fluid, typically water, through equipment or processes. Rather than directly cooling objects, liquid chillers absorb and transfer heat, making them indispensable in various applications.

Key Features:

- Removes heat efficiently through fluid circulation

- Ideal for machinery, lasers, and electronic devices

- Operates using a vapor compression refrigeration system

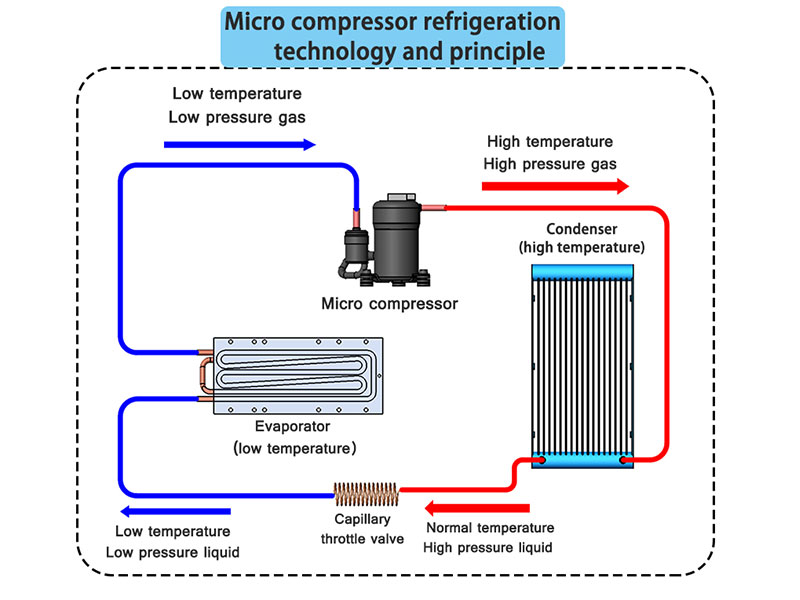

How Does a Liquid Chiller Work?

Liquid chillers function by transferring heat from a cooling fluid to a refrigerant in the system, which then disperses the heat into the environment.

Core Components:

- Compressor: Compresses the refrigerant and increases its temperature.

- Condenser: Transfers heat from the refrigerant to the environment.

- Expansion Valve: Lowers the refrigerant pressure and temperature.

- Evaporator: Absorbs heat from the coolant, cooling the circulating fluid.

This closed-loop system ensures efficient heat dissipation and precise temperature control.

Key Considerations for Choosing a Liquid Chiller

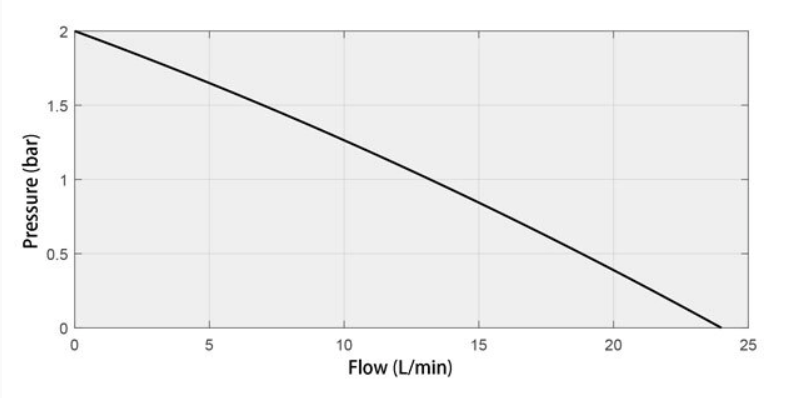

- Coolant Temperature and Flow Rate

- Ensure the coolant temperature aligns with your operational needs.

- The flow rate and pressure should allow efficient heat transfer without damaging the chiller’s components.

- Heat Load

- Calculate the heat load (in kW) to ensure the chiller has sufficient capacity to handle the system’s requirements.

- Installation Environment

- For indoor systems, consider heat and air quality conditions.

- Outdoor systems may require features like sump heaters or filters to manage extreme temperatures.

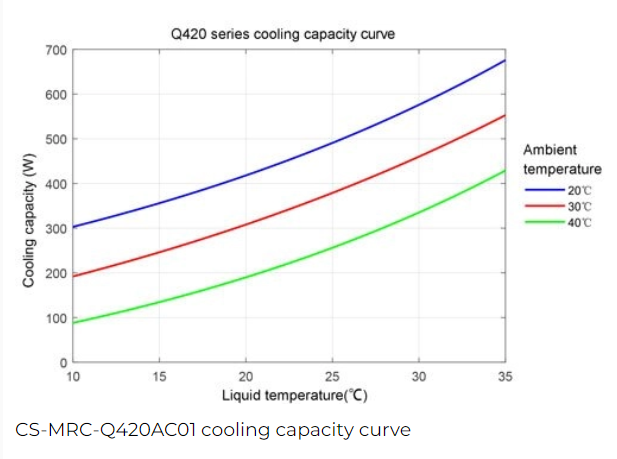

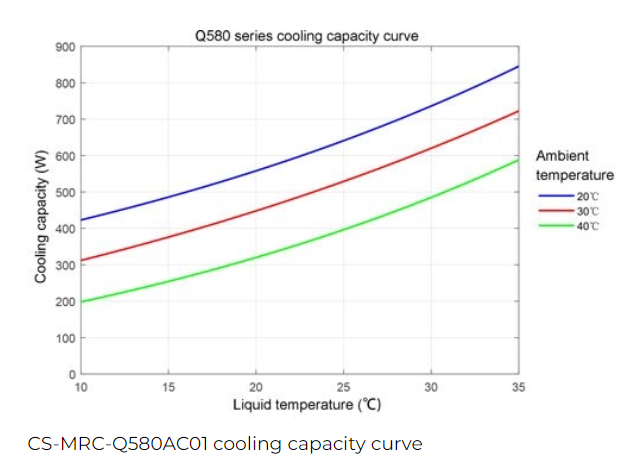

- Performance Curves

- Review cooling capacity and pump performance curves to verify the system meets operational demands.

- Heat Exchanger Efficiency

- Choose a system with efficient heat exchangers for better heat dissipation and energy efficiency.

Coolingstyle Liquid Chiller Systems: Compact and Powerful Solutions

Coolingstyle, a leader in liquid cooling technology, offers innovative solutions tailored for industrial and commercial needs. Their micro water chillers and rack-mounted chillers combine advanced technology, compact design, and energy efficiency.

Coolingstyle Micro Water Chiller

Designed for compact applications, this chiller is ideal for UV laser printers, 3D printing cooling, and other high-precision machinery.

Features:

- Compact Design: Dimensions of 345 x 248 x 215 mm

- Temperature Stability: ±0.1°C with PID control

- Cooling Capacity: 420W–580W

- Energy Efficient: Low power consumption with frequency conversion

- Lightweight: Weighs only 11kg

- Additional Features:

- Flow rate detector

- High-definition LCD monitor

- RS485 communication compatibility

Benefits:

- Space-saving and portable

- High-performance cooling with minimal noise and vibration

- Customizable pump options and power configurations

- Precise temperature control for optimized machinery performance

Cooling Capacity Curve

Pump Curve

Rack-Mounted Chiller

Coolingstyle’s rack-mounted chillers are ideal for industrial applications requiring robust cooling solutions.

Features:

- Available in 4U, 5U, and 6U sizes

- Cooling capacity: 400W–1200W

- Weight: 18kg–50kg

- High-definition LCD screen

- Custom power supply options (100–240V AC or 24V DC)

Benefits:

- Space-efficient, rack-mounted design

- Precise temperature control (±0.1°C) with PID system

- Multiple pump options for varied needs

- RS485 communication for integration with higher systems

Coolingstyle’s Innovation in Liquid Cooling

Coolingstyle’s chillers excel in:

- Temperature Precision: Maintain ±0.1°C for stable performance.

- Energy Efficiency: Optimized for low power consumption.

- Compact Design: Space-saving for diverse applications.

- Durability: Built for reliability and easy maintenance.

Conclusion

Liquid chillers are essential for maintaining equipment performance and efficiency in industrial and commercial settings. With options like Coolingstyle’s micro water chillers and rack-mounted chillers, businesses can achieve precise temperature control, enhanced reliability, and reduced energy costs.

Invest in Coolingstyle for a reliable, efficient, and compact cooling solution tailored to your needs!

1 thought on “Revolutionizing Cooling Efficiency: A Guide to Liquid Chiller Systems”

How does Coolingstyle’s liquid cooling technology enhance efficiency in industrial and commercial applications?

Regard IT Telkom