I’ve faced challenges with laser overheating in my work. It disrupts efficiency. Selecting the proper cooling system1 is critical. Let’s explore this decision.

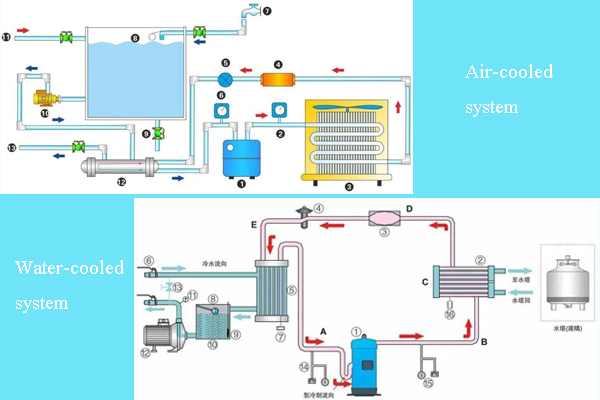

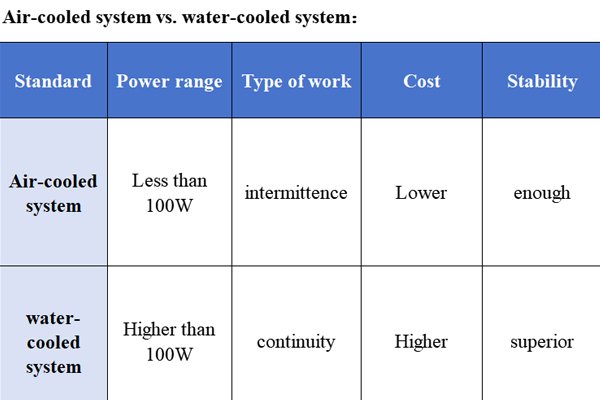

Air-cooled systems2 suit low-power lasers with simple, cost-effective designs. Water-cooled systems3 excel for higher power and stability. For low-power lasers, I prefer air-cooling.

I’ve evaluated both options extensively. Interested in the details? I’ll guide you through each aspect below.

What is the Air-Cooled Cooling System?

I’ve dealt with complex equipment setups. Air-cooled systems2 stand out for their simplicity. Are they effective for lasers?

Air-cooled systems2 use fans to dissipate heat. They work well for solid-state lasers4 between 10W and 100W with modest cooling needs.

I’ve implemented air-cooling in my designs. It’s practical. Let’s examine its strengths and limitations.

Dive Deeper: Air-Cooling for Laser Applications

I’ve applied air-cooling to various laser projects. It’s efficient for specific uses. I want to explain its role in low-power solid-state lasers4.

Mechanism of Air-Cooling

Fans circulate air over the laser components. Heat transfers out effectively. I’ve observed stable performance in lasers up to 100W.

Advantages and Trade-Offs

The design is straightforward. I appreciate the low cost and easy maintenance. However, its cooling capacity5 limits its use to lower power ranges.

Practical Application

I equipped a 20W laser with air-cooling. It performed reliably for short runs. Beyond that, heat buildup became an issue.

Here’s a structured overview:

| Feature | Details |

|---|---|

| Cooling Method | Airflow via fans |

| Power Range | 10W–100W |

| Cost | Low |

| Limitation | Reduced capacity at high loads |

I value air-cooling for its simplicity. It aligns with my focus on compact, cost-effective solutions at Coolingstyle. For lasers under 100W, it meets most needs. I’ve noticed it struggles with prolonged high-output tasks. Temperature spikes can affect performance. This makes it ideal for smaller, intermittent operations rather than heavy-duty use.

What is the Water-Cooled Cooling System?

I’ve encountered situations requiring robust cooling. Water-cooled systems promise efficiency. Do they justify the complexity?

Water-cooled systems circulate liquid to remove heat. They’re optimal for solid-state lasers4 exceeding 100W, ensuring consistent operation.

I’ve integrated water-cooling into several setups. It’s powerful. Let’s analyze its capabilities.

Dive Deeper: Water-Cooling’s Effectiveness

I’ve utilized water-cooling for demanding projects. It delivers results. I’ll detail its suitability for solid-state lasers4.

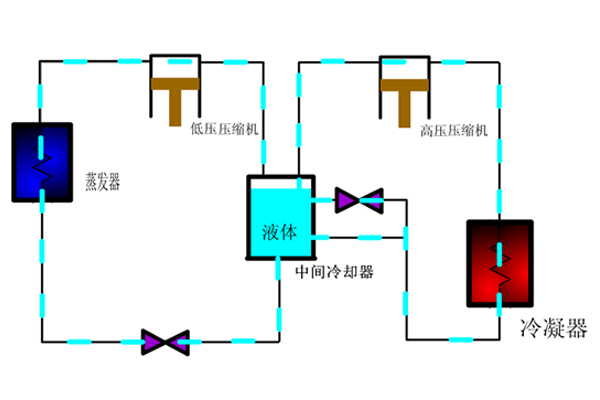

How Water-Cooling Functions

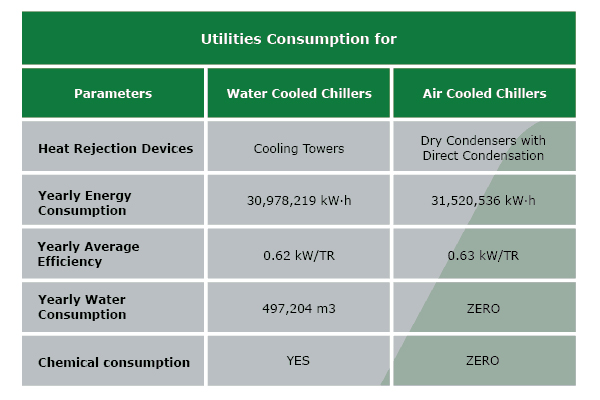

Water flows through channels near the laser. It absorbs heat efficiently. I’ve seen it maintain precise temperatures under load.

Benefits and Challenges

It prevents overheating effectively. I rely on it for stability. The downside? Higher costs and complex setups with chillers and pumps.

Field Experience

I cooled a 150W laser with water. It ran continuously without issues. Air-cooling couldn’t have managed that.

Here’s the breakdown:

| Feature | Details |

|---|---|

| Cooling Method | Liquid circulation |

| Power Range | Above 100W |

| Cost | Higher |

| Maintenance | Requires equipment |

I recognize water-cooling’s strength. It’s essential for lasers over 100W. At Coolingstyle, I use it for high-performance needs. The added complexity and cost make sense when stability is critical. For lower power, I find it excessive. My designs prioritize efficiency, and water-cooling shines in intensive applications.

What is the Low-Power Solid-State Laser?

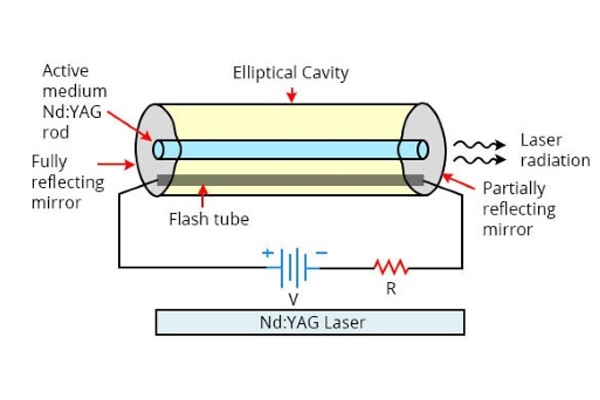

I’ve worked with many laser types. Low-power solid-state lasers6 are unique. What defines them?

Low-power solid-state lasers6 use crystals and operate below 100W. They’re efficient for precision tasks like marking and cutting.

I’ve designed these at Coolingstyle. They’re versatile. Let’s explore their characteristics.

Dive Deeper: Low-Power Laser Specifications

I’ve engineered these lasers for diverse clients. They’re compact yet effective. I’ll share what makes them distinct.

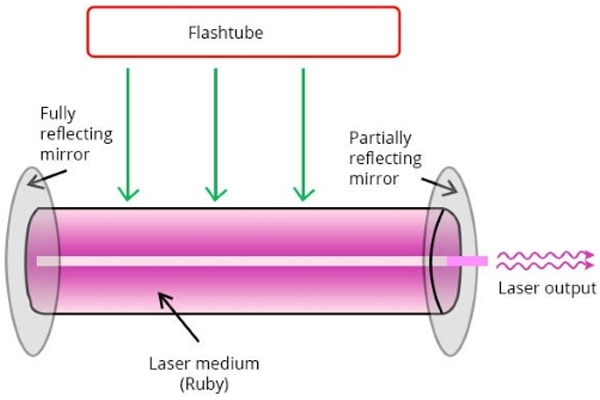

Operational Principles

Crystals like Nd:YAG7 generate the beam. I power them with diodes. They deliver consistent output for small-scale work.

Key Features

They consume less energy. I value their portability. Clients benefit from their adaptability in tight spaces.

Design Example

I built a 30W laser for engraving. It performed flawlessly with air-cooling. Power stayed within limits.

Here’s a summary:

| Feature | Details |

|---|---|

| Power Range | Below 100W |

| Core Material | Crystals (e.g., Nd:YAG) |

| Applications | Marking, cutting |

| Efficiency | High |

I depend on these lasers for precision. They suit my lightweight product focus. At Coolingstyle, we customize them for efficiency. Most stay under 100W, making air-cooling viable. I’ve deployed them in labs and factories. Their small footprint and reliability drive demand.

Why Does Solid-State Laser Need Cooling?

I’ve seen heat ruin laser performance. It’s a constant concern. Why is cooling essential?

Solid-state lasers produce heat in their crystals. Cooling prevents damage and maintains efficiency, especially under continuous use.

I’ve studied this issue closely. Let’s uncover the reasons.

Dive Deeper: Cooling’s Impact on Lasers

I’ve analyzed heat effects in my lab. Cooling is non-negotiable. I’ll explain why it’s vital for solid-state lasers4.

Heat Generation

Energy excites the crystal. Heat builds up quickly. I’ve measured temperature rises that distort beams without cooling.

Potential Risks

Excess heat damages components. I’ve replaced cracked crystals. It also reduces output quality over time.

Operational Insight

I ran a 50W laser uncooled briefly. Efficiency dropped fast. Cooling restored its performance.

Here’s the analysis:

| Aspect | Impact |

|---|---|

| Heat Source | Crystal activation |

| Without Cooling | Damage, efficiency loss |

| With Cooling | Stability, longevity |

| Solution | Air or water systems |

I never overlook cooling. Even low-power lasers generate heat. At Coolingstyle, we address this with tailored solutions. Air handles most cases below 100W. Water steps in for higher demands. Heat management ensures reliability—my clients expect nothing less.

How to Choose the Right Cooling System?

I’ve made cooling decisions for years. It’s a balance. How do I pick the best option?

For lasers under 100W, air-cooling8 is sufficient and cost-effective. Above 100W or for continuous use, water-cooling9 ensures stability.

I’ve refined my approach. Want to know how? Let’s break it down.

Dive Deeper: Cooling Selection Criteria10

I’ve matched systems to lasers repeatedly. Decisions hinge on clear factors. I’ll outline my process.

Power Considerations

Lasers below 100W run fine with air. I’ve tested this limit. Beyond that, water-cooling9 takes over.

Environmental Needs

Short runs favor air. I use water for long, stable operations. Duty cycle guides my choice.

Cost and Complexity

Air saves money and space. I opt for it when possible. Water’s expense pays off for precision.

Here’s my framework:

| Criterion | Air-Cooled | Water-Cooled |

|---|---|---|

| Power Range | Below 100W | Above 100W |

| Operation Type | Intermittent | Continuous |

| Cost | Lower | Higher |

| Stability | Adequate | Superior |

I choose air for most low-power lasers. It’s efficient and aligns with Coolingstyle’s compact ethos. Water-cooling fits higher power or critical tasks. I assess power, runtime, and budget. My clients need dependable systems—I deliver based on these principles.

My Insights!

I’ve spent years optimizing laser cooling. My perspective is clear. I’ve formed a strong opinion.

Air-cooling8 meets most low-power laser needs11—simple and effective. Water-cooling9 is reserved for power over 100W or high stability demands.

I recall a 30W laser project. Air worked perfectly. Water would’ve complicated it unnecessarily.

Conclusion

I’ve compared air and water cooling. Air suits low-power lasers under 100W. Water excels for higher power and stability.

About My Business

I’m Heidi Liu from Coolingstyle, China. Contact me at heidi@coolingstyle.com or visit www.coolingstyle.com. We provide water chillers12, micro cooling systems13, and custom solutions14 for B2B wholesale. Our precise, lightweight products serve lasers, medical, and more. We export to South Asia, North America, Europe, South Korea, and Japan. Clients include laser factories, OEMs, and medical systems. We offer top quality and R&D-driven customization. Find us on Alibaba or at trade shows!

-

Explore expert insights on selecting the best cooling system for solid-state lasers to enhance efficiency and performance. ↩

-

Discover the benefits of air-cooled systems for low-power lasers, including cost-effectiveness and simplicity. ↩ ↩ ↩

-

Learn why water-cooled systems provide superior performance and stability for high-power laser applications. ↩

-

Learn how solid-state lasers utilize air-cooling for optimal performance and efficiency in various applications. ↩ ↩ ↩ ↩ ↩

-

Discover the factors influencing cooling capacity to make informed decisions about cooling solutions for your projects. ↩

-

Discover the benefits and applications of low-power solid-state lasers, which are essential for precision tasks in various industries. ↩ ↩

-

Learn about Nd:YAG, a key crystal used in lasers, and its significance in generating high-quality laser beams. ↩

-

Learn about air-cooling mechanisms and their effectiveness for low-power lasers, which can save costs and space. ↩ ↩

-

Explore the advantages of water-cooling systems to understand why they are essential for high-power lasers and continuous operations. ↩ ↩ ↩

-

Discover the key factors in choosing the right cooling system for lasers to ensure optimal performance and reliability. ↩

-

Discover the specific cooling requirements for low-power lasers to optimize your projects effectively. ↩

-

Explore this link to understand how water chillers can enhance cooling efficiency and stability in various applications. ↩

-

Learn about micro cooling systems and their innovative uses in technology and medical fields. ↩

-

Discover how tailored cooling solutions can meet specific needs and improve performance in your industry. ↩