Many industries today are limited by space, yet require precise thermal management1. Traditional chillers are often too bulky or inefficient.

High-precision miniature chillers2 offer reliable cooling in compact spaces, ensuring high performance without sacrificing energy efficiency3 or design flexibility.

With the demand for lightweight, compact, and high-accuracy thermal control on the rise, miniature chillers are becoming the ideal solution for modern applications. In this article, I’ll explore the growing market need, the technologies that make these systems possible, and how our Coolingstyle products stand out.

The Growing Need for High-Precision Miniature Chillers?

Space constraints are everywhere—from laser engraving machines to medical therapy devices.

Miniature chillers4 are crucial in industries that require tight temperature control5 within compact environments6.

Where space meets precision

Modern equipment is smaller, smarter, and more powerful. These trends create a need for cooling systems that can deliver exact temperature control7 without taking up valuable real estate.

| Application | Size Constraint | Temperature Control Needed |

|---|---|---|

| UV Laser Systems8 | High | ±0.1℃ |

| Medical Devices | Medium | ±0.1℃ ~ ±0.01℃ |

| Outdoor Electronics | Very High | Stable range in extreme conditions |

| Scientific Equipment | Variable | Precise ramping and stability |

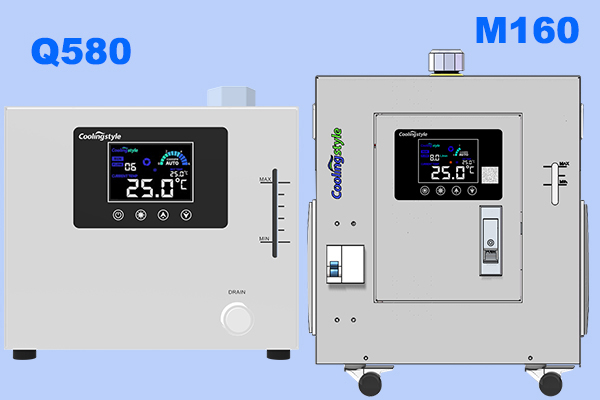

In all of these, traditional cooling units fall short—too bulky, too inefficient, or simply not accurate enough. This is where high-precision miniature chillers2 prove their value. For example, our Q580 series offers ±0.1℃ precision in a 10kg compact body—ideal for laser and lab integration.

Key Technologies Behind Precision Temperature Control?

High precision requires more than just small size—it needs smart engineering.

These chillers integrate micro DC inverter compressors9 and PID control10 for accurate, efficient temperature regulation.

Breaking it down: what makes the difference?

Micro DC Inverter Compressors9

-

Small and lightweight (less than 1kg)

-

High cooling density

-

Variable-speed control

-

Low noise and vibration

Advanced Temperature Algorithms11

We use a combination of:

-

PID control10 (proportional-integral-derivative)

-

Fuzzy logic

-

Custom I/O logic

These allow for dynamic control, matching heat loads in real time. For instance, the Q420 series can adjust cooling output automatically, maintaining temperature within ±0.1℃.

| Control Type | Response Time | Energy Efficiency | Accuracy |

|---|---|---|---|

| On/Off Control | Slow | Low | ±1.0℃ |

| PID Control | Fast | High | ±0.1℃ |

| AI/Adaptive PID | Fastest | Very High | ±0.01℃ |

Our in-house R&D ensures all systems, from firmware to algorithm tuning, meet the demanding needs of OEMs and integrators.

Innovations in Miniaturized Cooling System Design?

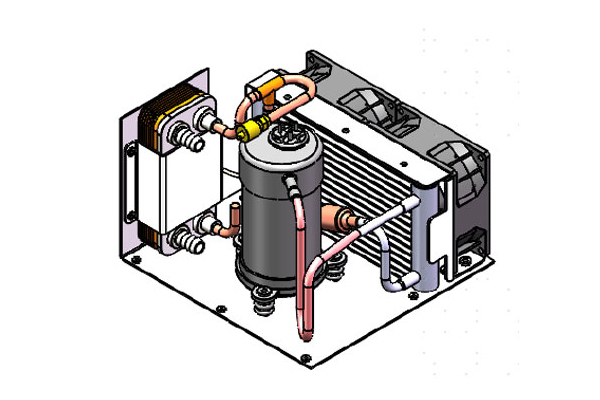

Miniaturization is not just shrinking components. It’s about smart integration12.

Our systems combine heat exchange13, pumps, controls, and displays into tightly packaged modules.

How do we do it?

Compact Mechanical Design

-

High-flow micro pumps

-

Modular enclosure with flame-retardant housing

Smart Interface15

-

LCD with real-time flow/temp display

-

RS485/RS232 communication for system integration

-

Plug-and-play architecture

| Feature | Q420 Series | Q580 Series |

|---|---|---|

| Size | 345×248×215 mm | 345×248×215 mm |

| Weight | ~10 kg | ~10 kg |

| Cooling Capacity | 420W | 580W |

| Control Accuracy | ±0.1℃ | ±0.1℃ |

| Communication | Optional RS485/232 | Optional RS485/232 |

We follow a design-for-manufacturing (DFM) process16 to ensure each module is easy to assemble, reliable to operate, and flexible for customization.

Industry Applications and Integration Scenarios?

High-precision miniature chillers are used in lasers, medical, scientific, and more.

From laser engraving17 to medical therapy pads18, these chillers meet the toughest demands in the smallest spaces.

Application Areas

Laser Equipment

-

Applications: Marking, cutting, engraving

-

Our solution: Q580 paired with 20–300W laser diodes19

-

Benefit: Stability, even in ±0.1℃ conditions

Medical Therapy Systems

-

Example: Cold therapy water pad20

-

Benefit: Silent operation, compact footprint, precise treatment temperature

Scientific and Lab Devices

-

Need: Stable operation across experiments

-

Our role: Provide units like M160 for rack-mounted precision cooling21

| Sector | Coolingstyle Solution | Benefit |

|---|---|---|

| Laser Machinery | Q420/Q580 | High accuracy, low noise |

| Medical Therapy | Custom micro chiller pad | Silent, mobile, FDA-ready |

| Lab Equipment | M160/Q4U3 rack series | Tight control, small footprint |

Energy Efficiency and Environmental Benefits?

Precision doesn’t mean waste. Our systems are built with efficiency in mind.

Coolingstyle chillers use R290 or R410a refrigerants22, inverter control23, and energy-saving logic24 for green operation.

Sustainability by design

-

R290: Environmentally friendly, no ozone depletion

-

Inverter compressors25: Run only when needed

-

Materials: Fire-retardant plastics, insulated casings

Our goal is to minimize total power consumption and GHG emissions26—without compromising cooling power. For instance, our M160 series offers 1600W cooling using just ~1000W input, with add-on auto-fill and heat modules.

| Model | Cooling Power | Power Draw | COP (Efficiency) | Refrigerant |

|---|---|---|---|---|

| Q420 | 420W | ~250W | 1.68 | R290 |

| Q580 | 580W | ~300W | 1.93 | R290 |

| M160 | 1600W | ~1000W | 1.60 | R410a |

Our future models are testing R290 and other natural refrigerants to push this even further.

Case Study: Coolingstyle’s Compact Precision Chillers27?

Let’s look at real-world success.

Our Q580 and M160 systems28 have been used in over 20 industries, from high-end laser29 to field medical devices.

Real customers, real solutions

Q580 in UV Laser Engraving

-

Installed in: Germany-based laser integrator

-

Challenge: High temperature accuracy30 within compact space

-

Result: 3-year stable operation, zero failure

M160 in Medical Device Cooling

-

Installed in: Taiwan rehabilitation device

-

Result: Passed all certification, now entering FDA audit

Custom Case: Tent Air Conditioner

-

6kg micro unit for camping

-

Uses: DC24V, R29032

-

Target: Military + outdoor leisure

Our R&D center in Shenzhen handles prototyping, testing, and scaling up all in one place.

Future Trends in Compact Precision Cooling?

We’re just getting started. Demand is evolving fast.

Compact precision chillers27 are moving toward smarter control33, cloud integration, and natural refrigerants34.

What’s next?

Smarter Control & IoT

-

Real-time cloud monitoring

-

Remote OTA firmware updates

Greener Tech

-

Shift to R290 and CO₂-based refrigerants36

-

Push toward zero-emission targets37

-

Solar-compatible off-grid solutions

Integration Ready

-

Rack-mount systems

-

Modular plug-in cooling elements

-

Pre-certified CE/FCC/UL packages for global distribution

At Coolingstyle, we aim to lead this evolution. With nearly 100 patents, we are committed to staying at the cutting edge of precise microenvironment thermal control.

Conclusion

Miniature chillers1 offer big performance in small packages—ideal for today’s compact, smart, and high-precision systems2.

-

Learn about the critical role of thermal management in enhancing performance and efficiency across various industries. ↩ ↩

-

Discover the advantages of high-precision miniature chillers for efficient thermal management in limited spaces. ↩ ↩ ↩

-

Explore effective strategies to boost energy efficiency in cooling systems, crucial for sustainability and cost savings. ↩

-

Explore how miniature chillers enhance efficiency and precision in various industries, making them essential for tight temperature control. ↩

-

Understanding the significance of tight temperature control can help you appreciate its impact on product quality and operational efficiency. ↩

-

Learn about the unique challenges faced in compact environments and how to effectively address them for optimal performance. ↩

-

Discover the critical role of temperature control in optimizing equipment performance and reliability across industries. ↩

-

Learn about the specific cooling needs of UV Laser Systems to ensure optimal performance and longevity. ↩

-

Understanding micro DC inverter compressors can enhance your knowledge of efficient temperature control technologies. ↩ ↩

-

Exploring PID control will provide insights into its critical role in achieving precise temperature management. ↩ ↩

-

Learn how Advanced Temperature Algorithms enhance HVAC performance and energy efficiency, ensuring optimal climate control. ↩

-

Discover how smart integration is revolutionizing technology and improving system performance across industries. ↩

-

Understanding heat exchange is crucial for optimizing cooling systems; this resource will deepen your knowledge. ↩

-

Explore this link to understand how integrated heat exchangers enhance efficiency and performance in mechanical designs. ↩

-

Discover how smart interfaces improve user experience and system integration in modern mechanical designs. ↩

-

Learn about the DFM process and how it optimizes product assembly and reliability in manufacturing. ↩

-

Discover the innovative uses of laser engraving technology and how it benefits different sectors. ↩

-

Learn about the advantages of medical therapy pads and their impact on patient care and recovery. ↩

-

Explore how laser diodes enhance precision and efficiency in various industrial applications, making them a valuable resource for your needs. ↩

-

Learn about the effectiveness and technology behind cold therapy water pads, which can improve patient care and comfort. ↩

-

Discover the importance of precision cooling in lab environments and how it ensures accurate experimental results. ↩

-

Exploring the differences between these refrigerants can inform your choices for environmentally friendly cooling solutions. ↩

-

Learning about inverter control can enhance your knowledge of energy-efficient technologies in cooling systems. ↩

-

Understanding energy-saving logic can help you optimize your HVAC systems for better efficiency and lower costs. ↩

-

Learn how inverter compressors optimize energy use, reducing power consumption and enhancing cooling efficiency in HVAC systems. ↩

-

Discover effective strategies to minimize GHG emissions in cooling technologies, contributing to a more sustainable future. ↩

-

Explore this link to understand how Compact Precision Chillers work and their diverse applications across various industries. ↩ ↩

-

Discover the unique features and benefits of Q580 and M160 systems that make them suitable for various industries. ↩

-

Learn about the industries that utilize high-end laser technology and how it impacts their operations. ↩

-

Explore this link to learn effective strategies for maintaining high temperature accuracy in limited spaces, crucial for various applications. ↩

-

Discover techniques and technologies that ensure precise temperature control, essential for medical device compliance and performance. ↩

-

Find out why DC24V and R290 are preferred choices for energy-efficient and eco-friendly air conditioning solutions in various applications. ↩

-

Discover how smarter control can enhance efficiency and performance in cooling systems, making them more reliable and cost-effective. ↩

-

Learn about the environmental advantages and efficiency of natural refrigerants, which are crucial for sustainable cooling solutions. ↩

-

Explore how predictive maintenance with AI can enhance efficiency and reduce costs in various industries. ↩

-

Learn about the environmental benefits and efficiency of using R290 and CO₂-based refrigerants in cooling systems. ↩

-

Discover strategies and technologies that can help businesses meet their zero-emission goals effectively. ↩