When it comes to refrigeration systems, size matters. But just how small can a refrigeration system be? To answer this question, we need to understand the key determining factors that influence the overall dimensions of such a system. As technology advances, the demand for compact and portable refrigeration solutions1 is increasing, particularly in applications like medical cooling2, personal air conditioning, and mobile refrigeration units3. However, extreme miniaturization comes with its own set of challenges and trade-offs.

Key Factors That Determine the Size of a Refrigeration System

- Compressor Size

The compressor is the most crucial component affecting the size of a refrigeration system. Currently, the smallest compressor available on the market is manufactured by ASPEN in the United States. This ultra-compact compressor sets a benchmark for miniaturized refrigeration solutions. Compressors are responsible for compressing and circulating the refrigerant, and their efficiency directly impacts the overall performance of the system. While micro-compressors4 enable significant size reduction, they often require advanced engineering and precise control systems to function efficiently without overheating or losing performance.

- Condenser and Evaporator

Apart from the compressor, the condenser and evaporator play significant roles in determining the overall footprint of a refrigeration system. These components are responsible for heat exchange, a process that requires sufficient surface area to function effectively. Miniaturizing them means achieving high thermal efficiency in a reduced space, which often necessitates the use of specialized materials, microchannel designs, or even phase-change technologies.

- Pipeline and System Layout

The arrangement of pipelines and overall system layout significantly impact the size and efficiency of a refrigeration system. Optimizing the refrigerant flow path can reduce unnecessary pipeline length, minimizing pressure drops and improving overall efficiency. Additionally, the use of microchannel heat exchangers (MCHE)5 allows for more compact and efficient heat transfer, further reducing the size of the refrigeration unit without compromising performance.

- Insulation and Structural Materials

The choice of insulation and structural materials plays a crucial role in determining the system’s final dimensions. Traditional foam-based insulation can be bulky, whereas advanced materials such as aerogels6 offer superior thermal resistance with a significantly thinner profile. Furthermore, using lightweight yet durable structural materials, such as high-strength alloys or engineered plastics, can reduce weight while maintaining system integrity, allowing for further miniaturization.

The Challenges of Miniaturization

The MOQ (Minimum Order Quantity) for small-size refrigeration components is typically low, leading to high production costs per unit. Manufacturing miniaturized components often involves advanced machining, tighter tolerances, and more precise assembly, all of which contribute to increased costs.

Due to the precision required in manufacturing small-scale refrigeration parts, the yield rate is lower than that of larger components. This contributes to an increase in final product costs, as manufacturers must account for potential defects and inefficiencies in production.

- Performance Limitations

Smaller refrigeration components often have to balance between efficiency and power. Heat dissipation becomes a critical challenge, and without proper design, a miniaturized system may suffer from overheating, reduced lifespan, or insufficient cooling capacity.

In China, many companies are attempting to develop small compressors, but they often struggle to optimize their performance effectively. Simply reducing the size of a compressor does not guarantee efficiency—precise control over speed, power consumption, and cooling capacity is necessary. Without proper optimization, these mini compressors10 may suffer from inefficiency, overheating, or poor temperature stability.

At Coolingstyle, we have tackled this challenge by optimizing the drive control11 and pairing our mini compressor with specially designed refrigeration components. Our advanced control system enables the compressor to reach a maximum speed of 6000 rpm, ensuring high-performance cooling in a compact form factor. Additionally, we have integrated a PID control algorithm12 to regulate the compressor’s variable frequency operation, allowing for precise temperature control that remains stable at the user’s desired setting.

- Cost vs. Size Trade-off

Users must carefully weigh the trade-off between cost and size13. While miniaturization14 offers space-saving advantages, it often comes at a significantly higher price. For applications where extreme compactness is not a necessity, slightly larger but more cost-effective solutions15 may be preferable.

Coolingstyle’s Solution

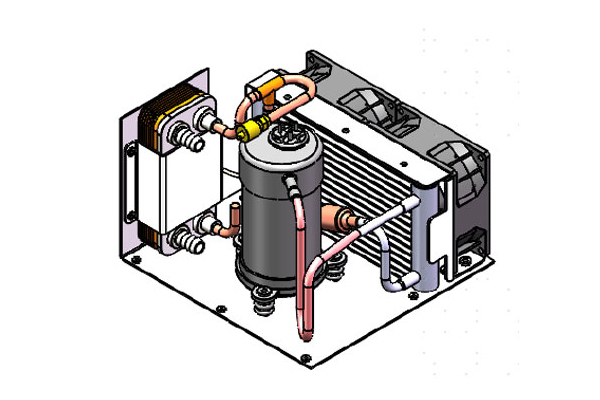

At Coolingstyle, we offer a self-developed and self-manufactured refrigeration module16 that provides an excellent balance between size, weight, and performance. Our module achieves a compact form factor with a weight of just 2.7 kg, making it one of the most lightweight and efficient solutions17 available. Unlike off-the-shelf mini compressors that may require complex integrations, our module is designed for seamless use in various applications, from portable air conditioning to specialized industrial cooling.

Compared to ASPEN’s offerings, our solution presents a compelling alternative, delivering efficient cooling performance18 in a highly compact design. Moreover, our in-house research and development allow us to continuously optimize the system for reliability, efficiency, and affordability.

The Future of Miniaturized Refrigeration

Looking ahead, miniaturized refrigeration will continue to evolve as materials and engineering techniques improve. Advances in solid-state cooling19, thermoelectric technology20, and AI-driven thermal management21 may further push the boundaries of what is possible in small-scale refrigeration. However, manufacturers and users alike must consider whether extreme miniaturization is necessary for their specific needs or if a balance between size, performance, and cost remains the smarter choice.

In conclusion, while the pursuit of miniaturization in refrigeration systems is exciting, it must be approached with careful consideration of cost, efficiency, and practicality. Coolingstyle’s innovative technology ensures a great balance, making our solution a smart choice for those looking for compact yet powerful refrigeration solutions.

-

Explore this link to discover innovative refrigeration technologies that meet the growing demand for smaller systems in various applications. ↩

-

Understanding medical cooling is crucial for ensuring the safety and efficacy of temperature-sensitive medical supplies and equipment. ↩

-

Learn about mobile refrigeration units to see how they are revolutionizing transport and storage of perishable goods in various industries. ↩

-

Explore how micro-compressors can enhance efficiency and reduce the size of refrigeration systems, making them a game-changer in the industry. ↩

-

Learn about the advantages of MCHE in optimizing heat transfer and reducing the footprint of refrigeration units. ↩

-

Discover how aerogels can revolutionize insulation, providing superior thermal resistance while minimizing space requirements. ↩

-

Understanding the factors behind high production costs can help manufacturers strategize and optimize their processes for better efficiency. ↩

-

Exploring the impact of lower yield rates can provide insights into production challenges and potential solutions for manufacturers. ↩

-

Learning about the optimization challenges can guide companies in improving their designs and achieving better performance in mini compressors. ↩

-

Explore this link to discover effective strategies for enhancing the performance and efficiency of mini compressors. ↩

-

Understanding drive control can help you grasp its critical role in maximizing compressor efficiency and performance. ↩

-

Learn how PID control algorithms can significantly enhance the stability and efficiency of compressor operations. ↩

-

Understanding the cost and size trade-off can help you make informed decisions in product design and selection. ↩

-

Exploring miniaturization can reveal its impact on technology and design, helping you assess its relevance to your needs. ↩

-

Discovering cost-effective solutions can enhance your design strategy and budget management, leading to better outcomes. ↩

-

Explore this link to understand how refrigeration modules enhance cooling efficiency and performance in various applications. ↩

-

Discover why lightweight cooling solutions are crucial for portability and energy efficiency in modern applications. ↩

-

Learn about the significance of efficient cooling performance in industrial settings and its benefits for operational efficiency. ↩

-

Explore the advantages of solid-state cooling, which could revolutionize miniaturized refrigeration with efficiency and reliability. ↩

-

Learn about thermoelectric technology and its role in enhancing the performance of miniaturized refrigeration systems. ↩

-

Discover how AI-driven thermal management can optimize refrigeration systems for better efficiency and performance. ↩