In today’s rapidly advancing laser industry, achieving high stability and operational precision requires effective thermal management. A dedicated laser cooling unit ensures consistent temperature control, prevents overheating, and preserves the performance of critical laser components. As a professional provider of micro-precision cooling solutions, Coolingstyle delivers compact and efficient cooling units designed specifically for advanced laser applications.

Why Laser Systems Need a Professional Laser Cooling Unit

Laser systems are extremely sensitive to heat. Even minor temperature fluctuations can cause:

- Power instability

- Wavelength drift

- Lower beam quality

- Reduced operational efficiency

- Damage to optical components

A high-performance laser cooling unit is essential for maintaining thermal balance in:

- Laser diodes

- CO₂ lasers

- Fiber lasers

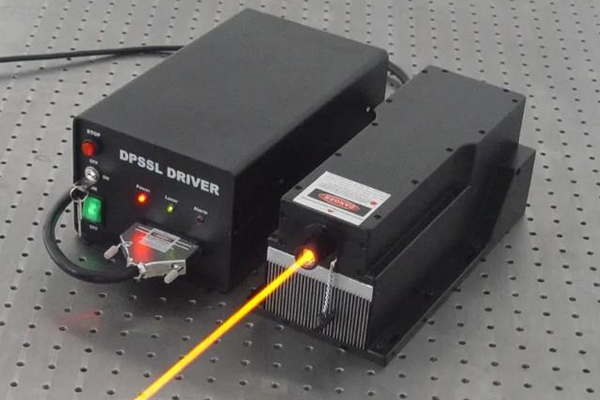

- DPSS lasers

- Nd:YAG laser sources

- Scanning galvo systems

By stabilizing these systems, Coolingstyle helps improve precision, extend equipment lifespan, and ensure consistent output quality.

Key Features of Coolingstyle Laser Cooling Units

1. Ultra-Precise Temperature Control

Coolingstyle’s advanced PID temperature control system achieves accuracy up to ±0.05°C, ensuring stable laser output in high-demand environments.

2. Compact Micro Cooling Design

Our cooling units are engineered for modern compact laser systems, offering high cooling efficiency with minimal footprint—ideal for small and mid-size OEM devices.

3. Low Noise and Low Vibration

Designed for laboratories, medical facilities, and research centers where quiet operation is essential.

4. Intelligent Monitoring and Protection

All Coolingstyle laser cooling units feature:

- Digital monitoring panels

- Coolant flow and temperature alerts

- Automatic fault protection

- Remote communication options for OEM integration

5. Broad Compatibility Across Laser Categories

Coolingstyle units support applications in:

- Laser engraving and cutting

- Laser marking & coding

- Medical and aesthetic laser devices

- Semiconductor inspection systems

- Scientific and laboratory research

6. OEM/ODM Customization

We offer full customization for equipment manufacturers, including cooling power, communication interfaces, pump types, and mechanical structure.

Applications of Laser Cooling Units in Various Industries

Industrial Manufacturing

Continuous operation lasers generate significant heat. A reliable laser cooling unit ensures smooth operation, reduced downtime, and superior processing quality.

Medical & Aesthetic Lasers

Medical laser devices rely on extremely stable temperatures to ensure patient safety, treatment accuracy, and equipment protection.

Semiconductor & Photonics

Laser-based inspection and precision microfabrication require ultra-high thermal stability to achieve reliable measurement performance.

Scientific Research

Universities and research centers depend on precise laser temperature control for spectroscopy, optics experiments, and advanced measurement applications.

Benefits of Coolingstyle Laser Cooling Units

- Stable laser performance during long operation

- Improved engraving, marking, and cutting accuracy

- Reduced maintenance and downtime

- Energy-efficient cooling technology

- Compact design ideal for OEM laser equipment

- Extended component lifespan

Conclusion

A reliable laser cooling unit is an indispensable component in modern laser systems. Coolingstyle continues to lead the industry in micro-precision cooling, providing solutions that ensure stable performance and long-term reliability for industrial, medical, scientific, and semiconductor laser applications.

Contact Coolingstyle

Looking for a customized laser cooling unit to enhance your system performance? Coolingstyle provides professional solutions tailored to your exact needs. Contact us today to learn more.