If you’re looking for a chiller to keep your UV laser printer running cool, you’ve come to the right place! In this blog post, we will discuss the different types of chillers available on the market and help you choose the best one for your needs. We’ll also provide information on how to install and use your new chiller. So, whether you’re a business owner or an individual looking to purchase a personal chiller, read on for more information!

What is a chiller system and what are its uses in UV laser printer cooling systems?

A chiller is a cooling unit that helps regulate the temperature of UV laser printers. By keeping the printer’s internal components cool, the chiller prevents overheating and damage to sensitive electronic parts. In addition, a properly cooled UV laser printer will produce higher-quality prints and have a longer lifespan.

How does a chiller system work?

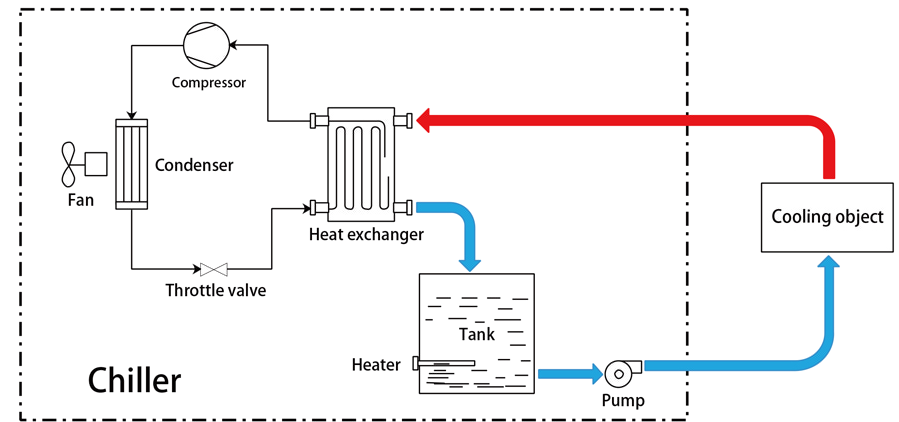

The water chiller can be best described as a device that is used to cool liquids by using the refrigeration cycle. The water chiller is able to remove the heat from the water and dissipate it into the surrounding atmosphere. This process allows for the cooling of the water to a temperature that is suitable for various applications.

What are the benefits of using water chilller?

The main reason why a UV printer needs a water chiller is to ensure that the printer’s ink stays at the correct temperature. If the ink is too hot, it can cause smudging or other printing problems. A water chiller helps to keep the ink at the correct temperature so that it can be properly printed onto the surface of the object.

If you’re looking for a water chiller for your UV printer, be sure to choose one that is specifically designed for printers. There are many different models of water chillers on the market, so you should be able to find one that meets your needs. Make sure to read reviews online before you make a purchase, so that you know you’re getting a quality product.

The different types of chillers on the market and how to choose the right one for your needs

When it comes to choosing a chiller for your UV laser printer, there are a few things you need to take into consideration.

First, you need to decide what type of cooling you need. There are two main types of chillers: air-cooled and water-cooled.

The air-cooled chiller uses air to make the heat exchanger function or cool. Most air-cooled chillers have propeller fans or undergo mechanical refrigeration cycles. They absorb rotating airs and condense the refrigerant and then remove and transmit the heat to the atmosphere. This type of chiller is ideal for smaller applications where space is limited. They’re also relatively affordable and easy to install. However, they can be noisy and can’t handle high heat loads.

A water-cooled chiller is a type of cooling system that uses water to transfer heat away from a building or structure. Water-cooled chillers are typically more giant than air-cooled chillers, making them a good choice for buildings or structures that require large amounts of cooling.

So, usually, when it comes to UV printer cooling solutions, we prefer using air-cooled water chillers.

What are the major advantage of the micro chillers for laser cooling?

For some confined space, it’s essential that the chiller has compact design. The basic working principal of the micro chiller is based on the air-cooled type chiller.

The micro cooling system is a kind of microclimate cooling system which consists of the compact liquid chiller module and electronic control system.

The liquid chiller module includes mini compressor, capillary throttle, heat exchangers(condenser and plate evaporator), pump and reservoir to contain liquid inside. With the tubing connects all the parts together, the water pump conveys refrigeration chilled water and circulate it to process cooling.

Micro chillers have many advantages as listed below:

- Compact design. The compact chillers saves your room. Most factory has limited room because the rent is so expensive. With compact design, this small device can be embedded easily to your laser equipment.

- High efficiency. The compressor inside is the inverter compressor, which is intelligent frequency conversion compressor. Usually the chiller needs less power to maintain temperature than cool down water temperature. So power consumption is changing when the heat load is different, which makes it very efficient. They can save your money on your energy bill so to improve the efficiency.

- High performance. The great performance includes accurate temperature control and excellent cooling performance. We use a heating rob inside to make the temperature more stable. The cooling capacity ranges from 400W to 1200W.

- Ultimate flexibility with power source. The mini dc compressor is only 860g weight. The defaut power is 220V or 110V. But if neccessary, we can offer custom design to make it output 24V, it assures end users to use the system with solar power or dc battery power.

- More choices for pump option. We have different pump specifications for choice. Sometimes customers may need small flow volume while some need big flow volume. Different pump choice enable customers more flexible.

- Lightest weight. The whole chiller device is only 11kg.

- RS485 function is available. It enables the chiller contact with the upper computer.

- Good reliability. We offer lifelong technical support to our customers. You can contact us 7*24 hours anytime!

Installation tips and advice for setting up your new micro chiller system

Now that you know the basics of micro chillers, let’s move on to facilitates installation.

Installing a micro chiller is relatively simple and can be done by following the instructions provided by the manufacturer.

- Open the package and check if the device is in good condition and the accessories are complete.

- Open the cap and add water. Add liquids (pure water or antifreeze solution) until it is above the minimum liquid level. In order to achieve better performance, it is recommended to reach as close as possible to the highest liquid level, and the maximum water beverage is about 1.8L.

- Be sure to connect the external waterway before starting operation. The inlet and outlet are both 10mm pu pipe quick-plug connectors, if necessary, users can transfer it by themselves.

- Connect the chiller system to 220V/110V/24V power, and press the switch to power on. After power on, the chiller system is in a stopped state. You need to operate the display screen to boot up, see the next section for details.

- If the external pipeline is long, the water level will drop slightly after the first start-up. You can replenish a proper amount of fluid from the water injection port.

- Once installed, your chiller system will need to be connected to a power source and turned on.

Maintenance tips to keep your chiller system running smoothly for years to come

As with any piece of refrigeration equipment, proper maintenance is key to keeping your chiller running smoothly with high performance.

Here are a few tips to help you keep your chiller in tip-top shape:

– Check the coolant level regularly and top up as needed.

– Inspect the hoses and connections for leaks or damage.

– Clean the condenser dust on a regular basis.

– Schedule yearly maintenance checks with a qualified technician.

By following these simple tips, you can ensure that your micro chiller will provide years of reliable service.

Now that you know everything there is to know about micro chillers, we hope you’ll consider purchasing one for your UV laser printer. If you have any questions or need help choosing the right model for your needs, our team of experts is always here to help. Contact us today and we’ll be happy to assist you. Thanks for reading!