In industries ranging from biomedical research to electronics and optics, precise temperature control is essential for ensuring performance, reliability, and accuracy. High-precision micro temperature control systems are key to maintaining stable conditions in demanding applications. In this article, we’ll explore the core technologies behind these advanced systems.

1. Temperature Sensors: The Foundation of Accuracy

At the core of any high-precision temperature control system is its ability to sense temperature with utmost accuracy. High-quality temperature sensors—such as thermistors, thermocouples, or semiconductor sensors—convert temperature into electrical signals that provide continuous feedback to the control system. This feedback is essential for maintaining the precise temperature needed for critical applications.

2. Control Algorithms: Ensuring Stability and Precision

The control algorithm is the brain of the temperature control system. It processes data from the sensors and generates control signals to adjust the system’s output. For accurate temperature regulation, the algorithm must be highly precise, responsive, and stable. Commonly used control algorithms include:

- PID Control: Proportional-Integral-Derivative control is widely used for continuous temperature regulation.

- Fuzzy Logic Control: Ideal for handling complex, non-linear systems.

- Model Predictive Control (MPC): Used in applications requiring predictive adjustments for improved control accuracy.

3. Actuators: Maintaining the Desired Temperature

To achieve the target temperature, actuators such as Peltier elements, heaters, or coolers, adjust the system’s temperature based on the control algorithm’s signals. The selection and calibration of actuators are critical for precision. Efficient actuators enable fast response times and energy savings, ensuring that the system meets the required temperature parameters.

4. System Integration and Optimization: Ensuring Reliability

High-precision temperature control systems require careful integration of components, including sensors, control algorithms, and actuators. Optimization tasks include:

- Hardware Design: Ensuring compatibility and robustness.

- Sensor Calibration: Achieving high levels of accuracy.

- Control Algorithm Tuning: Maximizing performance and stability.

- Reliability Testing: Verifying long-term performance under varied conditions.

Additionally, energy efficiency, compactness, and cost-effectiveness are key considerations in system design, ensuring that solutions are both effective and economical.

Applications of High-Precision Micro Temperature Control Systems

These systems have transformative applications across industries, enabling enhanced performance and enabling technological breakthroughs.

Biomedical Research: Accurate temperature control is crucial for experiments involving cells, proteins, and other biological samples, enabling precise study of cellular behavior and biochemical reactions.

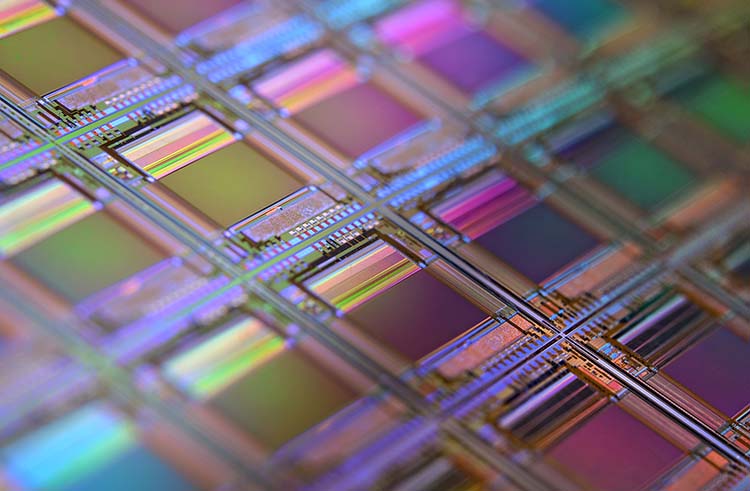

Microelectronics: In semiconductor manufacturing, stable temperature control ensures the reliability and longevity of integrated circuits and other critical electronic components.

Optics and Photonics: High-precision temperature regulation is vital for optical systems and laser technologies, ensuring consistent performance and accuracy in sensitive applications.

Conclusion: Driving Innovation with Precision

High-precision micro temperature control systems are indispensable across many fields, from scientific research to industrial manufacturing. By integrating accurate sensors, advanced control algorithms, and reliable actuators, these systems deliver precise, stable temperature regulation. As technology continues to evolve, advancements in micro temperature control promise even greater potential for research and development across diverse industries.

At Coolingstyle, we specialize in providing customized, high-performance temperature control solutions. Let us help you enhance the precision and efficiency of your next project with our cutting-edge products.