Efficient cooling is crucial for lasers, as a significant portion of electrical energy is converted into heat during operation. To address this challenge, Coolingstyle developed the CS-ARC-Q580A110 Miniature Chiller—a compact, lightweight, and highly precise cooling solution designed for a wide range of applications. Here’s a detailed breakdown of why this chiller stands out.

1. Choosing the Right Compressor

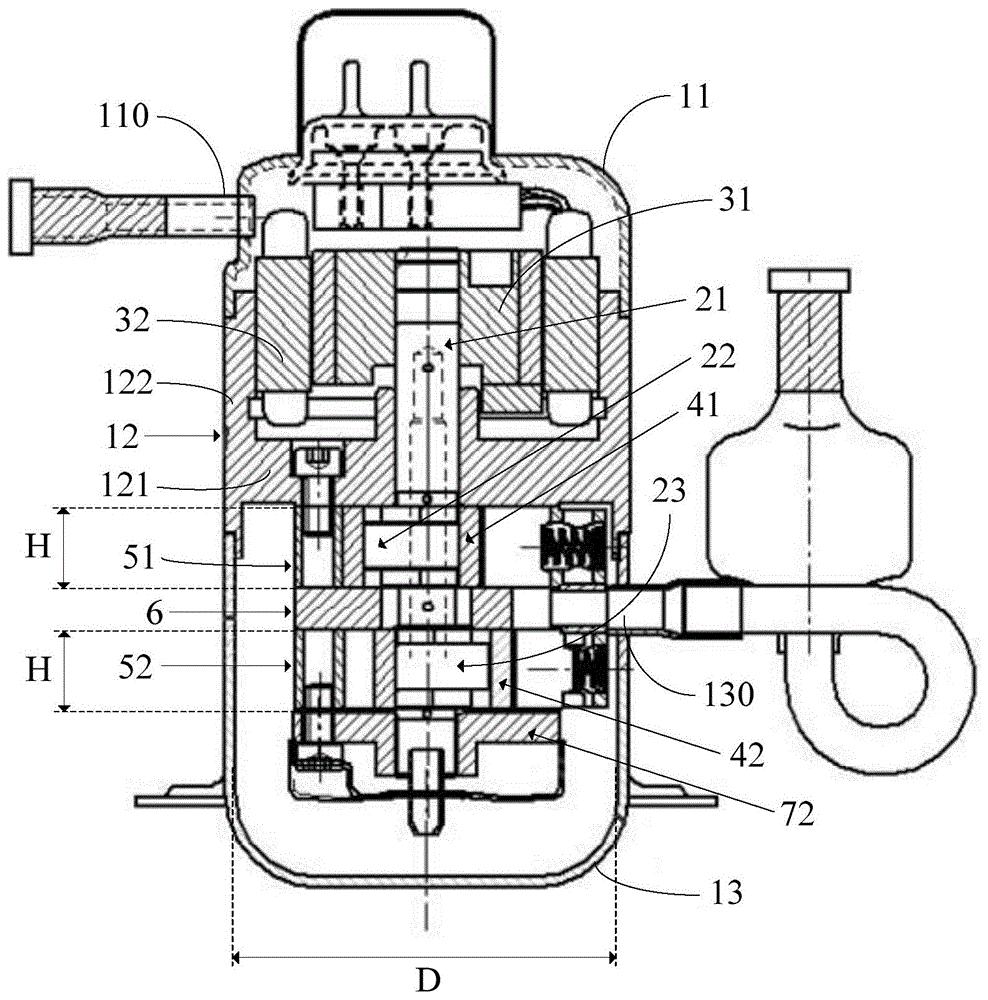

At the heart of the CS-MRC-Q580 lies a micro DC compressor with variable frequency. Despite its small size—just 90mm in height and under 1kg in weight—it delivers a remarkable cooling capacity of over 500W.

Key Features:

- Flexible Power Options: The compressor supports DC 24V with a voltage range of 20V–30V. It can run on Li-ion batteries or convert AC power (110V/220V) to DC 24V through an integrated power switch.

- Reduced Noise & Vibration: Two internal compression cylinders minimize vibration, even at high rotation speeds.

- Dynamic Cooling: The compressor’s rotational speed (2000–6000 RPM) adjusts automatically to match the heat load, ensuring efficient operation.

2. Gas and Liquid Cycles in the Chiller

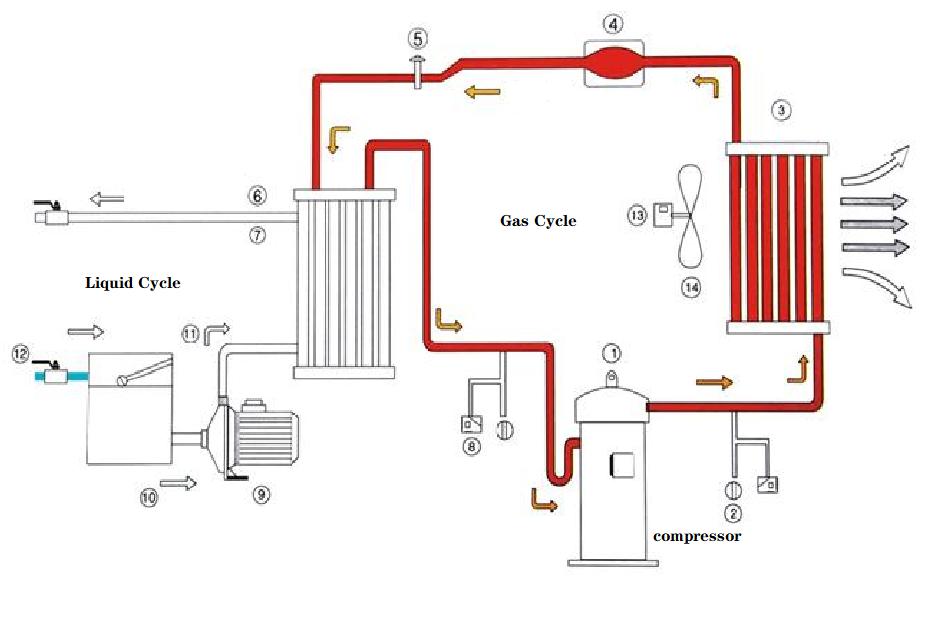

The CS-MRC-Q580’s design efficiently manages both the gas and liquid cycles for optimal cooling.

Liquid Cycle:

- A brushless DC pump delivers a flow rate of 2–5 L/min.

- A water tank equipped with a level sensor monitors liquid levels.

- The liquid flows from the tank through the evaporator and heat exchanger, then circulates to the heat load (e.g., a laser).

Additional Features:

- Low-Temperature Adaptation: A heater in the tank adjusts the liquid temperature for low ambient conditions.

- Flow Monitoring: A flow rate sensor detects changes, helping identify potential issues like dirty liquids.

3. Precision Temperature Control

The chiller uses a PID control algorithm for precise temperature regulation, achieving a stability of ±0.1°C.

How It Works:

- A 16-bit digital signal acquisition chip collects temperature signals.

- The PID controller adjusts the compressor speed to match the heat load.

- For low heat loads, a PWM-controlled heater compensates for excess cooling, maintaining the liquid temperature within a 0.1°C range.

4. Advanced Features of the CS-MRC-Q580

a) Real-Time Flow Rate Monitoring

- The built-in flow rate sensor displays the liquid flow rate on the screen.

- Alerts users to potential issues such as pump malfunctions or dirty liquid.

- Helps maintain optimal system performance by encouraging timely liquid replacement.

b) RS485 Communication Functionality

- Optional RS485 support allows seamless integration with external systems.

- Enables remote monitoring and control of parameters like compressor speed, liquid temperature, and flow rate.

- Facilitates system shutdown or temperature adjustments via RS485 commands.

c) User-Friendly Display

- The chiller features a clear display for real-time monitoring of system parameters, ensuring ease of operation and maintenance.

Why Choose Coolingstyle?

- Innovative Design: The CS-MRC-Q580 exemplifies advanced engineering with its compact size, lightweight build, and efficient performance.

- Precision Control: Achieves industry-leading temperature stability of ±0.1°C.

- Versatile Power Options: Compatible with both AC and DC power sources.

- Durability: Built for long-term operation with minimal maintenance needs.

- Enhanced Communication: Optional RS485 function for seamless integration with industrial systems.

| |||

| CS-MRC-Q420AC01 | CS-MRC-Q580AC01 | Model | XXXX |

| 420 | 580 | Cooling capacity(W) | 500 |

| DC inverter compressor | Compressor type | AC rotary compressor | |

| 620(MAX) | 640 (MAX) | Power consumption(W) | 760 |

| 35*25*22 | Chiller size(cm) | 58*29*47 | |

| 10.5 | 11 | Chiller net weight(kg) | 23 |

| ±0.1 | Temperature precision(℃) | ±0.2 |

Conclusion

The CS-ARC-Q580A111 Miniature Chiller is a game-changer in the field of industrial cooling, providing an efficient and precise solution for laser cooling and beyond. Whether you need reliable temperature control for industrial lasers, medical devices, or other sensitive equipment, Coolingstyle offers a robust and innovative solution tailored to your needs. Choose Coolingstyle for unparalleled cooling performance!