Are you looking for a compact yet powerful cooling system for your marking laser machine or other high-performance equipment? A micro refrigeration system could be the perfect solution! These systems ensure efficient cooling by focusing resources directly on heat-generating components, saving energy and maximizing performance.

In this guide, you’ll learn about micro cooling systems, their benefits, and what to consider when choosing one for your needs.

What is a Micro Cooling System?

A micro cooling system is a compact device designed to regulate the temperature of machinery, hardware, and confined areas. By efficiently collecting and dissipating heat, these systems keep equipment operating at optimal temperatures, preventing damage and enhancing longevity.

Key Features:

- Miniature compressors with variable cooling loads

- High cooling capacity for intense applications

- Ideal for:

- Laser cooling

- 3D printer cooling

- Medical therapy cooling

- Personal cooling systems

Factors to Consider When Choosing a Micro Cooling System

1. Cooling Capacity

Ensure the system has sufficient cooling capacity for your application. For high heat flux components, inadequate cooling power may lead to overheating and reduced efficiency.

2. Compressor Quality

The compressor determines the system’s cooling potential. A miniature compressor with higher cooling capacity ensures:

- Greater heat and mass transfer

- Superior thermal performance

- Low energy consumption

3. Energy Efficiency

Choose a system that offers:

- Low power consumption

- High heat transfer performance

- Environmentally friendly refrigerants

4. Additional Features

Look for features such as:

- Temperature stability (±0.1°C is ideal)

- Communication capabilities for smart integration

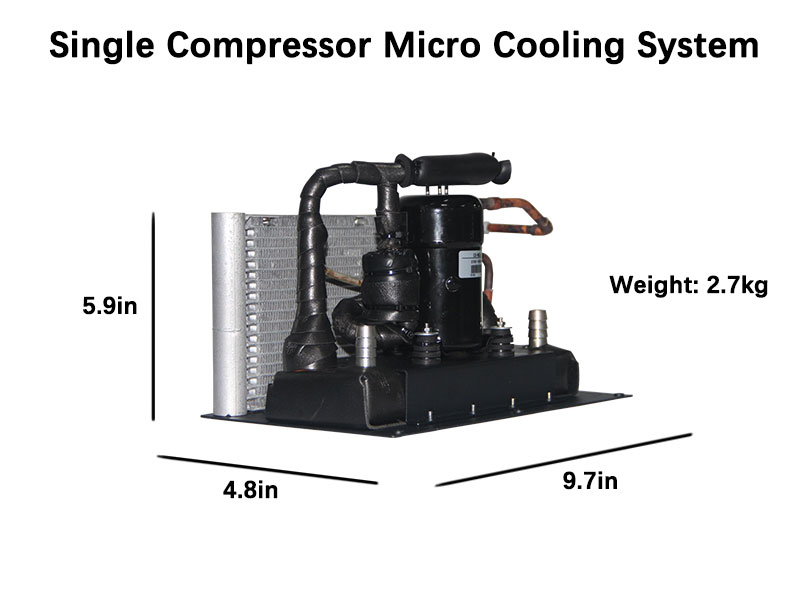

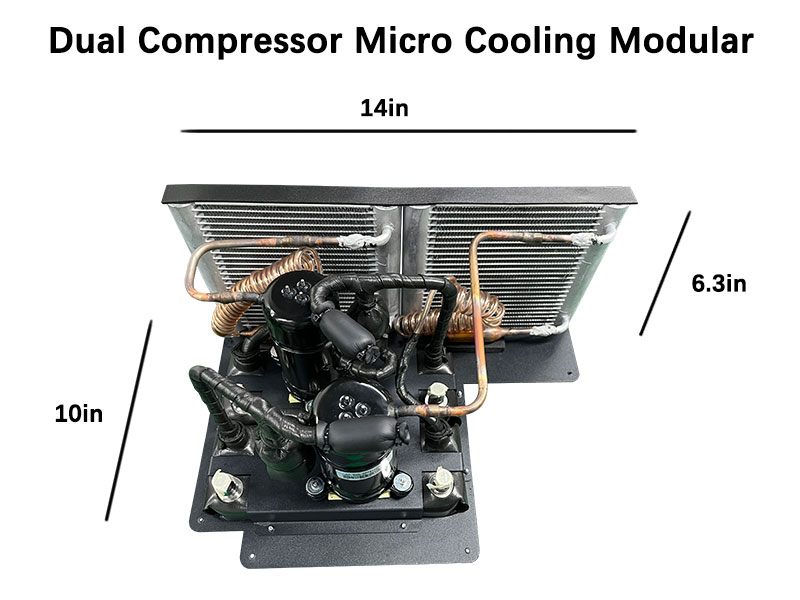

- Compact design for space-saving convenience

5. Durability and Maintenance

Opt for systems that are easy to maintain, with accessible replacement parts and reliable performance over time.

Advantages of Micro Refrigeration Systems

- Compact and Lightweight

- Ideal for space-constrained setups.

- Portable for diverse applications.

- Energy Efficient

- Consumes less power while delivering exceptional cooling performance.

- High Cooling Capacity

- Handles intense heat loads, especially in high-performance electronics.

- Enhanced Thermal Performance

- Superior heat transfer rates and reduced thermal resistance.

- Cost-Effective

- Affordable solution with lower operational costs.

Coolingstyle Micro Cooling Systems: Setting the Standard

Coolingstyle, a leader in micro refrigeration technology, offers innovative solutions that combine compact design, energy efficiency, and advanced cooling performance.

Top Features of Coolingstyle Systems:

- Cooling capacities ranging from 200W to 1200W

- Temperature stability at ±0.1°C

- Lightweight and easy-to-maintain designs

- Miniature compressors for high-performance applications

Their compact liquid chiller modules are perfect for cooling high heat flux components while minimizing energy consumption.

Innovative Cooling Technologies

Intrachip Micro Cooling Systems

Coolingstyle stays ahead of the curve with emerging technologies like microchannel cooling and intrachip cooling systems, designed for high-performance electronics.

- Microchannel Technology: Flows liquid coolant directly into chips, eliminating traditional heat sinks.

- HFE-7100 Refrigerant: Electrically insulated to prevent short circuits.

- Enhanced Efficiency: Effectively dissipates heat from next-gen high-performance processors.

Conclusion

A micro cooling system is a game-changer for industries requiring efficient and compact temperature regulation. Whether you’re cooling a laser, medical device, or high-performance computer, these systems deliver precision and reliability.

Coolingstyle’s micro refrigeration systems are at the forefront of innovation, offering unmatched cooling capacity, energy efficiency, and compact designs. Ready to upgrade your cooling system? Explore Coolingstyle’s solutions and keep your equipment running smoothly under any condition!