Amidst increasingly fierce global technological competition, the semiconductor industry is hailed as the “heart of modern industry.” Whether it’s smartphones, automotive electronics, AI chips, or core components of new energy devices, they all rely on semiconductor manufacturing technology. In semiconductor manufacturing, every nanometer-level breakthrough relies on meticulous control of the production environment. As chip process nodes continue to shrink, temperature control precision has become a key factor affecting product quality. In the semiconductor manufacturing process, from photolithography and etching to thin film deposition, nearly every step requires stringent temperature fluctuations.

The Booming Semiconductor Market

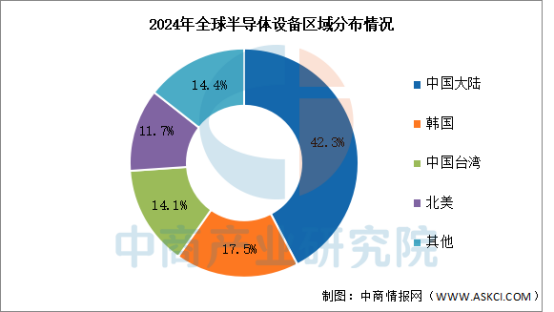

The global semiconductor industry is poised for certain growth in 2025. The World Semiconductor Trade Statistics (WSTS) forecasts that annual sales will reach $697.2 billion, an 11.2% year-on-year increase. Data center servers will contribute $86.4 billion to the incremental market, becoming the core growth engine. The GPU sector is poised for explosive growth, projected to reach $51 billion at a 27% growth rate. High-bandwidth memory (HBM), the golden partner of AI chips, is projected to account for $21 billion of the HBM4 market alone.

China, the world’s largest consumer market, accounts for over 35% of the total. Its integrated circuit exports exceeded $150 billion in 2024, and its trade deficit continues to narrow, demonstrating significant progress in domestic substitution efforts.

The “Temperature Guardian” of Semiconductor Manufacturing

Semiconductor manufacturing demands increasingly stringent precision, and so too do temperature control standards.

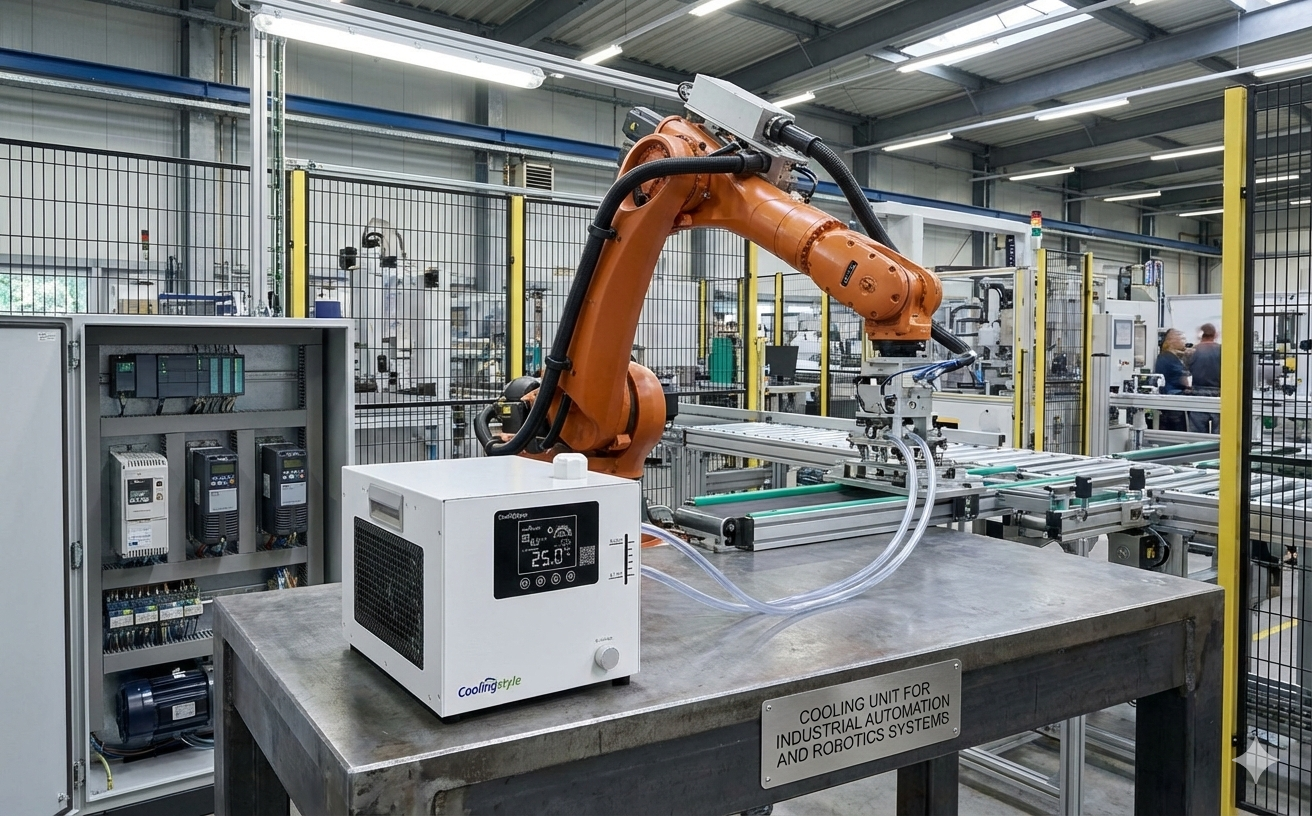

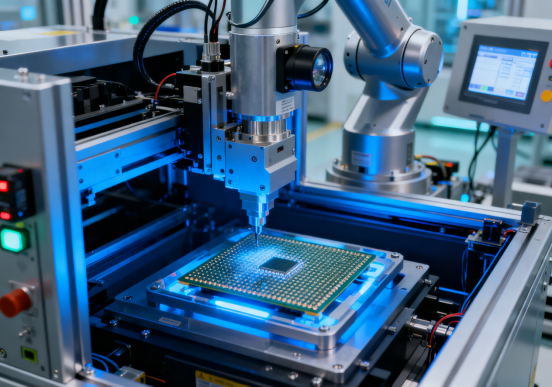

In advanced processes, temperature fluctuations must be controlled within ±0.1°C, and cleanliness must meet ISO Class 1 standards. Even slight deviations can lead to chip circuit defects. From photolithography light source Coolingstyle to etching process temperature control, from ion implanter thermal management to maintaining the packaging and testing environment, every process requires precise temperature control. Chillers remove heat from equipment through a circulating coolant system while preventing contaminants, creating a stable microenvironment for semiconductor manufacturing. In testing equipment, chiller accuracy directly impacts measurement data accuracy. In measuring equipment like scanning electron microscopes, the temperature stability of the electron gun is crucial to image quality.

In process line applications, the demand for chillers varies across different stages. The photolithography process requires a fast-response circulation system to cope with sudden temperature increases on the wafer, while the etching process demands multi-channel independent temperature control. Coolingstyle Technologies’ semiconductor test three-temperature sorter temperature control equipment is a low-temperature cascade refrigeration semiconductor refrigerant unit, designed for temperature control in semiconductor production and testing. It can detect temperatures in both low and ambient temperature ranges from -55°C to 150°C, ensuring stable and reliable semiconductor processes from front-end to back-end.

Future Trends in Semiconductor Temperature Control Technology

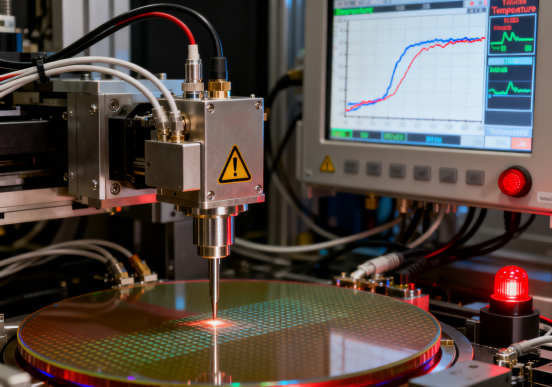

As semiconductor processes advance toward 2nm and smaller nodes, refined and stable temperature control becomes increasingly critical. Semiconductor manufacturing equipment must continuously operate in a more stable and precise environment, placing higher demands on temperature control equipment.

A global semiconductor leader requires a R&D environment temperature stability of ±0.01°C; a global communications equipment leader requires an even higher stability of ±0.005°C. Leading domestic and international companies are striving for ultra-precision control of ±0.001°C. (Data source: Zhongguancun Online)

This means that semiconductor temperature control technology must continue to push the boundaries of physics to provide a more robust environmental guarantee for chip manufacturing. The development of semiconductor chiller technology not only represents progress in temperature control but also provides crucial support for the entire semiconductor industry’s advancement toward higher precision and smaller nanoscale processes.

In the future development of the semiconductor industry, with the explosive growth in demand for AI computing power and the continuous shrinking of chip process nodes, the importance of precision temperature control technology will become increasingly prominent.Coolingstyle Era will continue to deepen its expertise in micro-environment Coolingstyle and further expand into cutting-edge areas such as AI chip Coolingstyle.