I. Introduction

As technology and industry advance, low-temperature refrigeration plays a crucial role across various sectors. What is the cascade refrigeration system? It is a refrigeration system that utilizes two or more different refrigerants operating at different temperature ranges to achieve extremely low temperatures. For more details, see Wikipedia on Cascade Refrigeration and Frigel’s Cascade Refrigeration System. What is the purpose of a cascade system? Its main purpose is to overcome the temperature limitations of a single refrigeration cycle, providing lower temperature environments to meet the demands of special applications.

II. Working Principle of Cascade Refrigeration Systems

How does a cascade air system work? A cascade refrigeration system connects two independent refrigeration cycles (high-temperature stage and low-temperature stage). The high-temperature stage uses primary refrigerant R404, and the low-temperature stage uses secondary refrigerant R23. For a deeper understanding, refer to Natural Refrigerants on Cascade Systems and ScienceDirect on Auto-Cascade Systems. The two stages exchange heat through an intermediate heat exchanger, forming a cascade cycle that achieves lower temperatures. Cascade refrigeration system P-h diagram analysis helps in understanding the thermodynamic changes at each stage of the refrigeration process, providing deeper insights into the system’s operation.

III. Technical Features of Our Company’s Cascade Refrigeration Unit

Who manufactures cascade refrigeration systems? As a leading manufacturer of refrigeration equipment, our company Coolingstyle had successfully customized a series of cascade refrigeration units for our customer.

Product Parameters and Performance Advantages

- High-Efficiency Output

- Output Power: 1.5 HP

- Load Capacity:

- 200W @ -55℃

- 300W @ -40℃

- 800W @ +25℃

- Energy Saving and Environmental Protection

- Power Consumption: 10A, 220V

- Refrigerant Selection: Primary refrigerant R404 and secondary refrigerant R23, both eco-friendly.

- Precise Temperature Control

- Temperature Range: -55℃ to 150℃, control accuracy of ±1.0℃

- Temperature Control Precision: ±0.5℃

- Compact Design and Easy Integration

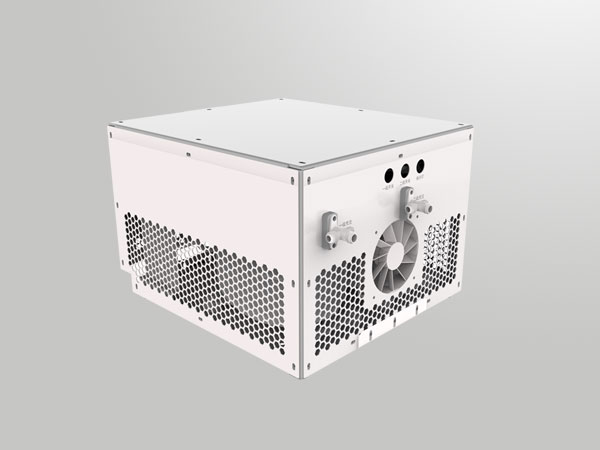

- Refrigeration Unit Dimensions: 300×550×600mm

- Control Box Dimensions: 440×438×362mm

- Low Water Consumption

- Water Consumption: 30L/min per unit

The application of an auto-cascade refrigeration system introduces intelligent monitoring and automatic adjustment features, enhancing operational efficiency and reliability.

IV. Problems and Solutions in Cascade Refrigeration Systems

During operation, cascade refrigeration systems may encounter technical challenges such as refrigerant leakage and system instability. We offer comprehensive solutions to these issues, including regular maintenance, advanced sealing technologies, and intelligent monitoring systems to ensure long-term stable operation. For more insights on challenges faced by these systems, see Frigel’s Overview and Innovative Refrigeration Systems.

V. Applications of Cascade Refrigeration Systems and Their Rationale

Why is the cascade refrigeration system used? It achieves ultra-low temperatures unattainable by single refrigeration cycles and offers high efficiency, stability, and strong controllability. Broad Application Fields

- Laser Industry: Provides stable ultra-low temperature cooling for laser cutting and welding equipment, ensuring processing precision and equipment longevity.

- Medical Field: Delivers precise temperature control in MRI equipment and low-temperature laboratories, meeting stringent medical standards.

- Food Processing and Chemical Industry: Used in quick freezing, low-temperature preservation, and special chemical processes, ensuring product quality and production safety.

For applications in specific industries, refer to ScienceDirect on Low-Temperature Applications and Natural Refrigerants on Food Processing.

VI. Future Development Trends

The use of environmentally friendly refrigerants will continue to deepen, reducing environmental impact and aligning with global green development trends. For insights into future trends in refrigeration technology, see Optimized Cascade Process and ScienceDirect on Auto-Cascade Systems. Intelligent and digital upgrades will drive cascade refrigeration systems toward the Internet of Things, achieving remote monitoring, data analysis, and intelligent adjustment, further enhancing user experience and equipment efficiency.

VII. Conclusion

With outstanding technical advantages and wide application fields, cascade refrigeration units have become the preferred solution for efficient low-temperature cooling. Our company is committed to continuous technological innovation, providing superior products and services across various industries. For further reading on technological advancements in this area, refer to Wikipedia on Cascade Refrigeration and Frigel’s Overview.