With the rapid adoption of laser technology in industrial manufacturing, advertising, and precision electronics processing, the demand for stable operation and high-precision performance in laser cutting and engraving equipment1 continues to rise. An efficient and reliable cooling system2 has become essential to ensure both performance and longevity.

Among various cooling methods, industrial chillers3 stand out as the most effective solution. By providing accurate temperature control and efficient heat dissipation, chillers are now indispensable in laser systems. As a leading high-tech enterprise specializing in precision temperature control, Coolingstyle4 delivers advanced micro DC inverter chillers designed specifically to meet the cooling requirements of laser applications.

Cooling Requirements of Laser Equipment5

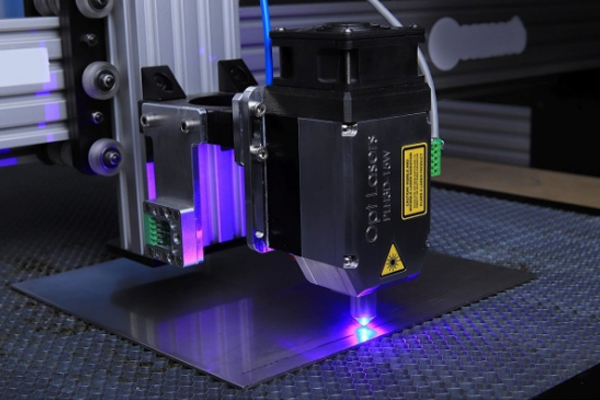

How Laser Cutting and Engraving Work

Laser machines generate high-energy-density beams6 that are focused through optical systems to cut, engrave, or mark materials. This process, while precise and efficient, produces significant amounts of heat.

Why Laser Systems Generate Heat

Key components such as the laser source7, power supply, and optical lenses operate under high loads and produce heat continuously. Fiber lasers and CO₂ lasers, despite their high efficiency, still generate substantial thermal losses. If heat is not dissipated effectively, it can lead to instability, reduced output, or even permanent equipment damage.

Importance of Cooling

Stable cooling8 ensures consistent laser output, extends equipment lifespan, and improves processing accuracy. For high-load, long-duration applications, chillers play a critical role in preventing thermal drift, beam distortion, and other performance issues.

The Role and Principle of a Chiller

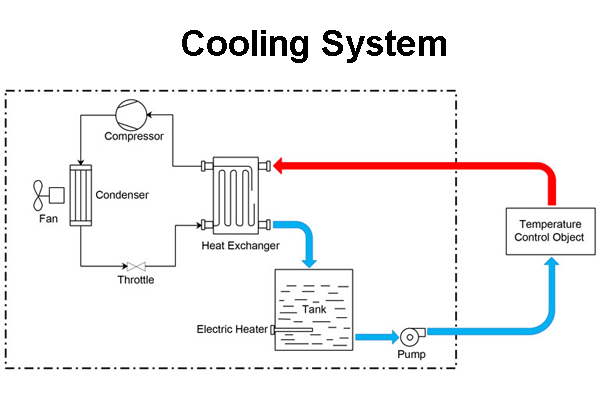

How a Chiller Reduces Laser Temperature

Chillers lower the temperature of circulating coolant via a refrigeration cycle, then deliver it to the laser’s cooling circuit. The coolant absorbs heat from components and returns to the chiller for re-cooling, forming a closed-loop system9.

Working Principle

A chiller is composed of a compressor, condenser, expansion valve, evaporator, pump, and reservoir10 During operation, the compressor compresses refrigerant, which releases heat in the condenser. After throttling and evaporation, the refrigerant absorbs heat from the cooling water, lowering its temperature.

Coolingstyle’s chillers feature high-efficiency DC inverter compressors11 and intelligent temperature control systems, ensuring ±0.1°C accuracy12, ideal for laser systems requiring ultra-stable performance.

Key Components and Functions

- Compressor13: The heart of the chiller, driving refrigerant circulation.

- Evaporator: Absorbs heat from the water to achieve cooling.

- Condenser: Releases heat into the external environment.

- Pump: Circulates coolant through the system and laser device.

- Control System14: Monitors temperature, flow, and pressure for stable operation.

Choosing and Configuring the Right Chiller

Matching Chiller Capacity to Laser Power

The cooling capacity should be 1.2–1.5 times the rated laser power15 to ensure safety margin. For example, a 1500W laser requires at least an 1800W chiller.

Cooling Capacity Considerations

Besides power, the chiller’s ability to maintain stable cooling under high ambient temperatures is critical. Coolingstyle’s M160 Series Industrial Chiller16 delivers 1600W cooling capacity and includes heating functions, ensuring stable operation across seasonal and environmental conditions.

Brand and Model Selection

With numerous options in the market, selecting a manufacturer with proven technology and service is vital. Coolingstyle, with over a decade of expertise in micro refrigeration17, has built a strong reputation in laser, medical, and scientific industries by offering reliable products and comprehensive after-sales support18.

Using and Maintaining a Laser Chiller

Daily Usage Guidelines

- Ensure the water tank is filled before startup.

- Place the unit in a well-ventilated environment away from direct sunlight.

- Use purified water or antifreeze to prevent scaling.

- Never operate without water.

Regular Maintenance

Conduct monthly inspections of compressor performance, electrical parameters, and condenser cleanliness. Address abnormalities immediately to prevent downtime.

Common Troubleshooting

- No cooling effect: May indicate dirty condenser or insufficient refrigerant.

- Water leakage: Check pipe connections.

- Alarms: Refer to error codes for diagnostics.

Coolingstyle chillers are equipped with multi-level protection features19 such as water flow alarms20, high-temperature warnings, and compressor overload protection for safe operation.

Cleaning and Care

- Clean filters and condensers regularly.

- Check for impurities in water tanks and pipes.

- For long-term storage, drain and dry the water tank.

Conclusion

Laser chillers are essential for the stable, efficient, and precise operation21 of laser cutting and engraving equipment. By maintaining temperature stability, they safeguard equipment reliability and enhance processing quality.

With a strong focus on micro-environment temperature control technology, Coolingstyle has accumulated extensive experience in supporting the laser industry. Our independently developed DC inverter chillers22 are widely recognized for their efficiency, intelligence, and reliability.

Coolingstyle will continue driving innovation to deliver smarter, more energy-efficient, and customized cooling solutions for the laser industry.

For inquiries about selection or customized solutions, please contact Coolingstyle. We are ready to provide you with a one-stop cooling solution.

- Explore this link to learn essential maintenance tips that enhance the performance and lifespan of your laser equipment. ↩︎

- Discover how a proper cooling system can significantly boost the efficiency and longevity of your laser cutting operations. ↩︎

- Explore this link to understand how industrial chillers enhance efficiency and precision in laser applications. ↩︎

- Discover Coolingstyle’s innovative chillers that are tailored for laser systems, ensuring optimal performance and reliability. ↩︎

- Understanding cooling requirements is crucial for maintaining laser equipment efficiency and longevity. ↩︎

- Exploring high-energy-density beams can enhance your knowledge of laser cutting and engraving processes. ↩︎

- Understanding the laser source is crucial for grasping how heat generation impacts laser performance. ↩︎

- Exploring the importance of cooling can help you learn how to maintain optimal laser performance and longevity. ↩︎

- Exploring this concept will help you grasp the efficiency and effectiveness of chillers in various applications. ↩︎

- Understanding these components is crucial for optimizing chiller performance and efficiency. ↩︎

- Exploring this technology can reveal how it enhances energy savings and performance in cooling systems. ↩︎

- Understanding this accuracy is crucial for applications like laser systems, ensuring optimal performance. ↩︎

- Understanding the compressor’s function is crucial for optimizing chiller performance and efficiency. ↩︎

- Exploring control systems can enhance your knowledge of temperature regulation and system stability in chillers. ↩︎

- Understanding the cooling capacity needed for lasers is crucial for optimal performance and safety. ↩︎

- Exploring the M160 Series can provide insights into reliable cooling solutions for industrial applications. ↩︎

- Exploring micro refrigeration will provide insights into its applications and innovations, crucial for industries like medical and scientific. ↩︎

- Understanding the importance of reliable products and after-sales support can enhance your purchasing decisions and ensure long-term satisfaction. ↩︎

- Understanding these features can enhance your knowledge of safety and efficiency in laser chiller operations. ↩︎

- Exploring this topic will help you ensure optimal performance and prevent potential issues with your chiller. ↩︎

- Understanding these benefits can help you optimize your laser cutting processes and improve overall productivity. ↩︎

- Exploring the advantages of DC inverter chillers can lead to better energy efficiency and performance in your cooling solutions. ↩︎