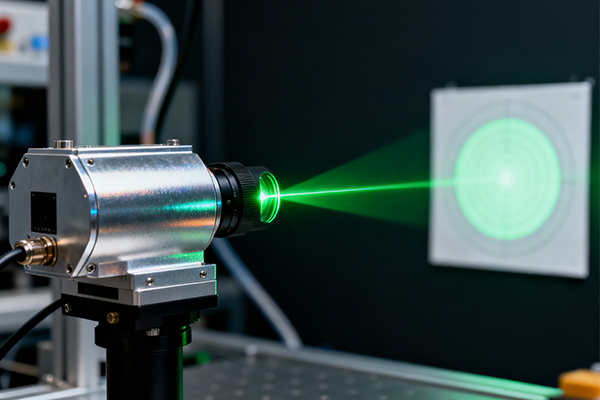

As smart manufacturing and new productivity models reshape global industries, laser technology1 has become a driving force for industrial upgrading. From new energy vehicle components and semiconductor fabrication to medical imaging and precision optics, lasers are redefining production efficiency and accuracy. With this rapid expansion, however, the demand for stable and precise temperature control2 has become increasingly critical to ensure consistent laser performance and long-term system reliability.

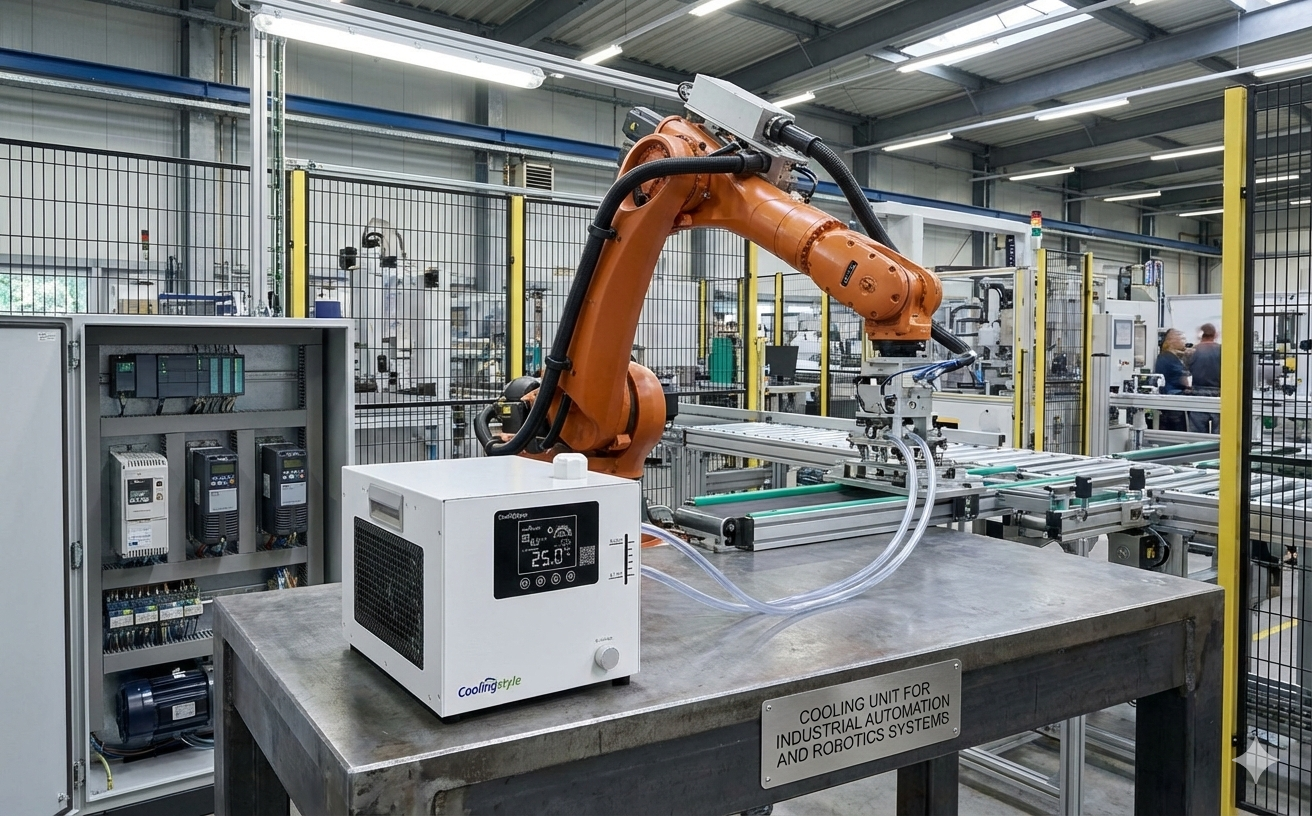

Against this backdrop, the laser chiller3 plays a vital role in maintaining thermal stability. As a leading manufacturer of compact and high-precision cooling systems, Coolingstyle Technology Co., Ltd.4 has focused on developing intelligent, energy-efficient, and eco-friendly cooling solutions that enable laser equipment to operate with maximum precision and reliability.

The Evolution of China’s Laser Industry

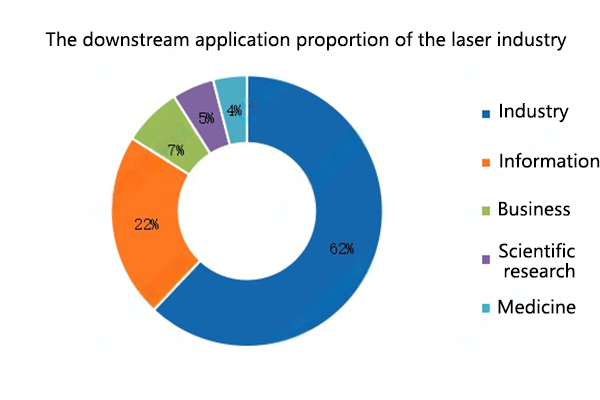

China’s laser industry has entered a stage of high-quality growth, covering the entire supply chain—from laser sources and optical systems to complete equipment integration. Rapid advances in ultrafast and fiber laser technologies5 have significantly enhanced domestic production capabilities and expanded applications into sectors such as new energy, semiconductors, medical devices, and consumer electronics.

However, laser systems generate substantial heat during high-power operation. Without effective cooling, performance degradation, power instability, or even component damage may occur. Hence, a reliable and precise cooling system6 is not just supportive—it is essential to ensure output stability, extend lifespan, and safeguard equipment investment.

Market Growth and Rising Demand for Temperature Stability

According to multiple industry reports, the global laser market7 is projected to exceed USD 25 billion by 2026, with China showing an annual growth rate above 10 %. This expansion is largely driven by the surging adoption of high-power and high-precision laser systems in EV manufacturing, 3C electronics, medical aesthetics, and optical communications.

To meet these evolving needs, Coolingstyle has launched its Q420, Q5U3, and M160 series laser chillers, featuring proprietary DC inverter micro-compressor technology8 capable of maintaining ±0.01 °C temperature precision. These compact and high-performance chillers are widely used in fiber laser marking, chip packaging, and glass micromachining, delivering continuous and stable cooling performance for demanding industrial environments.

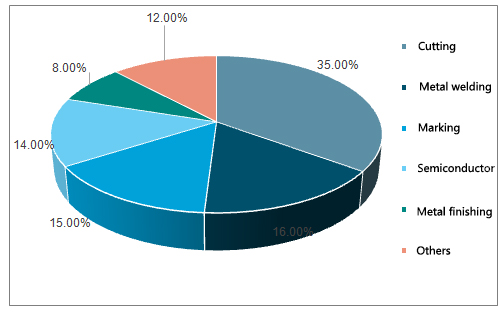

Expanding Applications of Laser Technology

Laser Welding9

In EV battery tab and casing welding, high-precision chillers help maintain beam stability and ensure consistent weld quality.

Laser Cutting and Marking

Desktop laser chillers have become standard in small- and medium-power systems for metal enclosures, consumer electronics, and precision components, enabling uninterrupted production.

Semiconductor and Photonics Manufacturing10

Ultrafast laser applications such as wafer dicing and glass drilling require rapid and precise temperature response. Coolingstyle chillers provide dynamic heat compensation for superior optical stability.

Scientific Research and Medical Use

In optical imaging, laser surgery, and photodynamic therapy, low-noise and precise temperature control ensure safe and reliable operation.

Intelligence and Sustainability Define the Future

The laser industry is evolving toward higher power density, smaller size, and greater intelligence11. With the integration of AI and IoT technologies, temperature control is shifting from passive cooling to active predictive management12.

By leveraging sensor feedback and data modeling, next-generation chillers can anticipate heat load changes and automatically adjust performance for optimized thermal balance.

Coolingstyle has been at the forefront of this transformation. Its intelligent laser chillers support remote monitoring, automatic adjustment, and early warning diagnostics. Equipped with R290 natural refrigerant, each unit can save up to 3,000 kWh of electricity per year, helping customers achieve both energy efficiency and carbon reduction goals.

Precision Cooling: The Foundation of Laser Performance

In laser processing, beam stability directly determines accuracy and yield. Even a 0.1 °C deviation13 can lead to beam drift, power loss, or system shutdown. Therefore, precision temperature control is not merely a technical feature—it is a core factor influencing productivity, product quality, and brand reputation.

With over a decade of expertise in micro-environment refrigeration14 and high-precision thermal management, Coolingstyle continues to deliver advanced, reliable, and efficient cooling solutions for laser applications worldwide. Moving forward, the company remains committed to driving the laser industry toward a more intelligent, sustainable, and precision-driven future.

- Explore this link to discover cutting-edge innovations in laser technology that are transforming manufacturing processes. ↩︎

- Understanding the significance of temperature control can enhance your knowledge of laser performance and system reliability. ↩︎

- Understanding laser chillers is crucial for optimizing laser equipment performance and ensuring thermal stability. ↩︎

- Exploring Coolingstyle’s offerings can provide insights into advanced cooling solutions for laser technology. ↩︎

- Explore this link to understand how these technologies are revolutionizing industries and enhancing production capabilities. ↩︎

- Discover the importance of cooling systems in maintaining laser performance and prolonging equipment lifespan. ↩︎

- Explore this link to understand the trends and projections in the global laser market, which is crucial for industry insights. ↩︎

- Discover the mechanics and benefits of this technology, essential for maintaining precision in cooling systems. ↩︎

- Explore this link to understand how Laser Welding enhances efficiency and quality in EV battery production. ↩︎

- Discover the role of laser technology in advancing Semiconductor and Photonics Manufacturing for innovative applications. ↩︎

- Explore how advancements in laser technology can enhance efficiency and performance in various applications. ↩︎

- Learn about the innovative approaches in temperature control that can lead to significant energy savings and efficiency. ↩︎

- Understanding the effects of temperature deviations can enhance your laser processing accuracy and efficiency. ↩︎

- Exploring micro-environment refrigeration can provide insights into advanced cooling solutions for various industries. ↩︎