OEM equipment manufacturers across industries increasingly require tailored thermal management solutions to meet specific performance, size, and integration requirements. Standard cooling products often fail to address these challenges. A custom cooling unit designed for OEM applications enables higher system efficiency, reliability, and long-term competitiveness.

Coolingstyle specializes in designing and manufacturing custom cooling units for OEM customers, delivering precision cooling solutions that align perfectly with equipment design and operational demands.

1. Why OEM Applications Require Custom Cooling Units

OEM systems often operate under unique thermal and mechanical constraints. Generic cooling solutions may compromise performance or limit system scalability.

- Non-standard installation space and layout

- Specific cooling capacity and temperature stability requirements

- Integration with proprietary control systems

- Industry-specific environmental standards

A customized cooling unit ensures seamless integration and optimal thermal performance.

2. OEM Industries Served by Coolingstyle

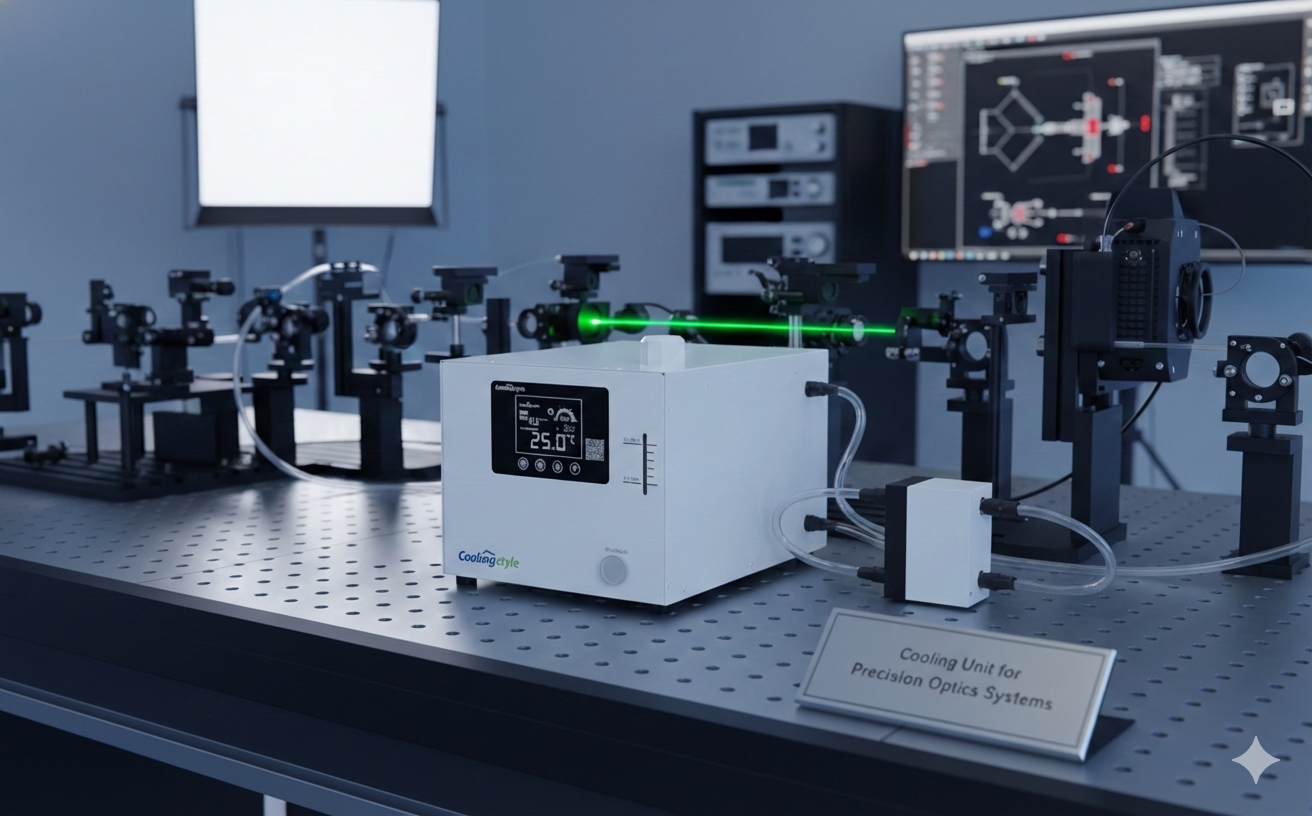

2.1 Laser and Photonics Equipment

Laser cutting, marking, and measurement systems demand stable thermal control to protect optical components and ensure precision.

2.2 Semiconductor and Electronics Manufacturing

Process tools, inspection systems, and testing platforms rely on customized cooling units to maintain process consistency.

2.3 Medical and Scientific Instruments

Medical imaging, laboratory analyzers, and diagnostic equipment require quiet, stable, and compact cooling solutions.

2.4 Industrial Automation and Advanced Manufacturing

Automation systems and precision machinery benefit from cooling units designed for continuous operation and compact integration.

3. Key Design Considerations for OEM Cooling Units

- Precise temperature control and stability

- Customized form factor and mounting options

- Electrical and control interface compatibility

- Noise, vibration, and energy efficiency requirements

- Long-term reliability and serviceability

4. Coolingstyle OEM Customization Capabilities

- Tailored cooling capacity for specific heat loads

- Compact and modular designs for OEM integration

- Advanced temperature control with high precision

- Flexible interface options for system compatibility

- Full engineering support from concept to production

5. Engineering Process for Custom Cooling Units

5.1 Requirement Analysis

Coolingstyle works closely with OEM customers to define thermal, mechanical, and operational requirements.

5.2 Thermal Design and Simulation

Thermal modeling ensures optimized heat dissipation and stable temperature control.

5.3 Prototype Development and Testing

Prototypes are rigorously tested to validate performance and reliability.

5.4 Mass Production and Quality Control

Coolingstyle supports scalable production with consistent quality standards.

6. Benefits of Partnering with Coolingstyle

- Reduced development time and engineering risk

- Improved system performance and reliability

- Enhanced product differentiation

- Long-term technical support and customization

Conclusion

A custom cooling unit is a strategic component for OEM manufacturers seeking optimized performance and competitive advantage. Coolingstyle delivers engineered cooling solutions that integrate seamlessly into OEM systems and support long-term product success.