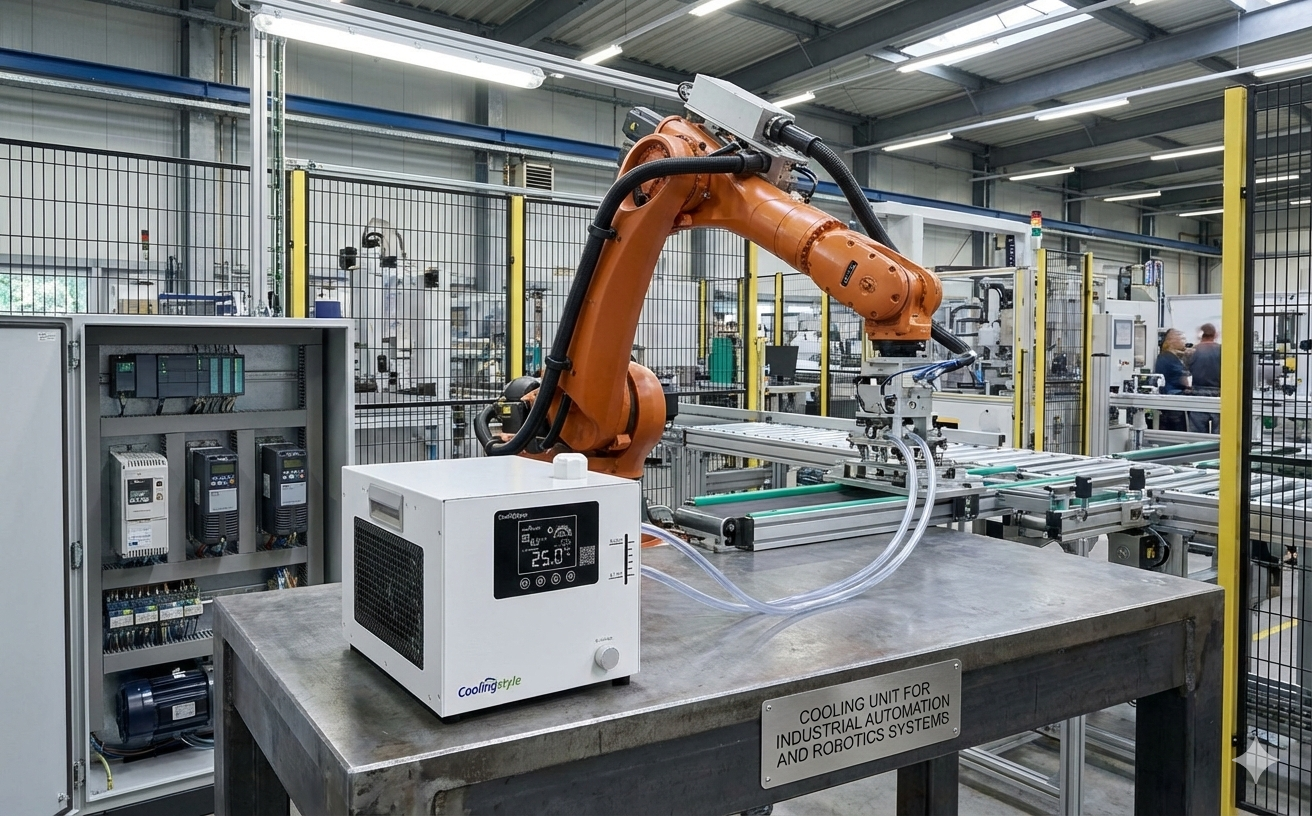

Industrial automation and robotic systems are transforming modern manufacturing by improving efficiency, precision, and productivity. As these systems operate continuously and handle complex tasks, thermal management becomes critical. A reliable cooling unit ensures stable operation of control electronics, motors, and vision systems.

Coolingstyle provides high-precision cooling units designed to support industrial automation, robotics, and machine vision applications where accuracy and reliability are essential.

1. Thermal Challenges in Industrial Automation

Automation systems often integrate multiple heat-generating components within compact enclosures.

- Heat from servo drives and motor controllers

- High power density in control cabinets

- Continuous operation in factory environments

- Temperature sensitivity of vision and sensing electronics

An advanced cooling unit helps maintain stable temperatures, preventing performance drift and system downtime.

2. Applications of Cooling Units in Automation Systems

2.1 Industrial Robots and Motion Control

Robotic arms and motion control systems rely on precision electronics that require consistent thermal conditions. Cooling units help ensure accurate positioning and repeatability.

2.2 Machine Vision and Inspection Systems

Vision cameras and image processing units are sensitive to temperature fluctuations. Precision cooling units enhance image stability and inspection accuracy.

2.3 Control Cabinets and Automation Panels

Control cabinets house multiple heat-generating components. Compact cooling units provide effective thermal management within limited space.

3. Key Requirements for Automation Cooling Units

- Compact design for integration into control enclosures

- Precise temperature control for sensitive electronics

- High reliability for continuous production cycles

- Low maintenance and energy-efficient operation

- Compatibility with industrial standards

Coolingstyle cooling units are engineered to meet these requirements across diverse automation applications.

4. Advantages of Coolingstyle Cooling Units

- Stable thermal performance for precision automation

- Compact and modular designs for flexible integration

- Customizable cooling solutions for unique system layouts

- Enhanced system reliability and reduced downtime

- Long operational lifespan in industrial environments

5. Engineering and Customization Capabilities

5.1 Intelligent Temperature Control

Coolingstyle cooling units incorporate intelligent control systems that adapt to changing thermal loads in automation processes.

5.2 System Integration Flexibility

Cooling units can be customized for size, cooling capacity, and interface requirements to match automation equipment.

5.3 Reliability and Safety Features

Built-in monitoring and protection functions ensure safe and reliable operation in demanding factory conditions.

6. Future Trends in Industrial Automation Cooling

As automation systems become more compact and powerful, thermal management will play an increasingly important role.

- Higher power density electronics requiring precise cooling

- Compact cooling solutions for collaborative robots

- Improved energy efficiency in industrial cooling systems

Conclusion

A high-performance cooling unit is essential for industrial automation, robotics, and machine vision systems. Coolingstyle delivers reliable and precise cooling solutions that enhance performance, stability, and long-term reliability in modern manufacturing environments.