In the semiconductor industry, temperature stability is directly linked to production accuracy, wafer yield, and long-term device performance. As manufacturing processes continue to shrink to nanometer-level geometries, precise thermal management has become more important than ever. This is where a high-precision chiller plays a critical role.

Coolingstyle specializes in advanced micro high-precision chillers designed specifically for semiconductor equipment. With temperature stability reaching ±0.05°C, our systems ensure consistent cooling performance across the most demanding processes.

Why Temperature Precision Matters in Semiconductor Manufacturing

Semiconductor fabrication involves heat-sensitive processes such as lithography, etching, deposition, CMP, and electrical testing. Even the smallest temperature fluctuation—sometimes as little as 0.1°C—can lead to:

- Pattern distortion during lithography

- Critical dimension (CD) variations

- Optical misalignment in exposure systems

- Unstable plasma characteristics in etching

- Reduced wafer yield and increased scrap rate

That’s why semiconductor manufacturers rely on high-precision chillers to maintain ultra-stable cooling throughout the production line.

Key Applications of Coolingstyle Micro High-Precision Chillers

1. Lithography (Photolithography) Cooling

Lithography systems contain high-power UV light sources, optical lenses, and precision alignment modules. These components generate significant heat and require extremely stable temperature control. Coolingstyle micro chillers ensure:

- Stable light source wavelength

- Improved exposure accuracy

- Reduced optical drift

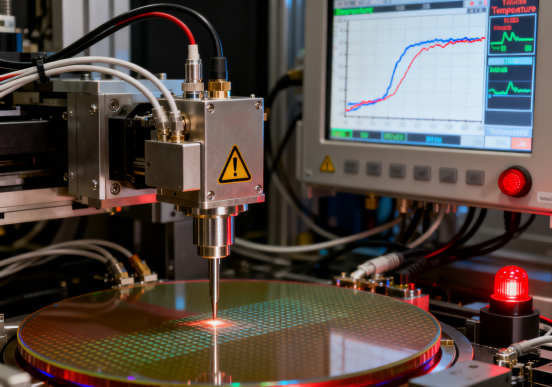

2. Plasma Etching and Dry Etching Equipment

Etching chambers rely on consistent temperature control to maintain plasma stability and etching uniformity. A Coolingstyle high-precision chiller helps maintain:

- Stable plasma behavior

- Consistent ion distribution

- More uniform etch results

3. Semiconductor Laser Devices

Lasers are widely used in wafer inspection, marking, dicing, and optical communication testing. These systems are highly sensitive to temperature fluctuations. Our micro high-precision chillers offer:

- Laser wavelength stability

- Longer laser lifespan

- Higher measurement accuracy

4. Test & Measurement Instruments

Semiconductor testing requires ultra-stable thermal conditions to avoid measurement drift and ensure repeatability. Coolingstyle micro chillers provide:

- Low noise and smooth temperature control

- Ultra-stable thermal environments

- Higher testing consistency

Why Choose Coolingstyle for Semiconductor Cooling?

- ±0.05°C high-precision control for critical semiconductor processes

- Compact micro-size designs suitable for tight equipment integration

- Customizable cooling systems including mini chillers, cooling units, and refrigeration modules

- Energy-efficient and long-life operation for 24/7 cleanroom environments

- Direct manufacturer (OEM/ODM) support for semiconductor equipment builders

The Importance of High-Precision Chillers in Modern Semiconductor Production

As chip designs become more advanced, traditional cooling systems are no longer able to meet the industry’s thermal stability requirements. A high-precision chiller is now considered an essential component for ensuring:

- Stable process temperature

- Higher wafer yield

- Consistent device performance

- Reduced downtime and maintenance

Coolingstyle continues to lead in the field of micro and precision cooling, supporting the semiconductor industry with reliable, scalable, and customizable thermal solutions.

Conclusion

With more semiconductor processes requiring tight temperature control, the demand for high-precision chillers continues to grow. Coolingstyle’s micro high-precision chillers deliver the accuracy, reliability, and compactness needed for today’s advanced semiconductor manufacturing environments.

For customized cooling solutions or OEM/ODM support, visit Coolingstyle — your trusted partner in micro high-precision cooling technology.