Energy efficiency in cooling systems is crucial for reducing operational costs and environmental impact. DC inverter chillers1 have revolutionized temperature control by offering superior efficiency compared to fixed-frequency chillers2. Understanding how these systems work and their differences can help businesses make informed decisions.

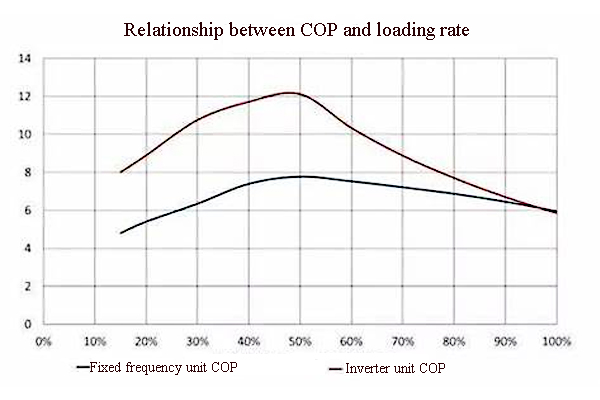

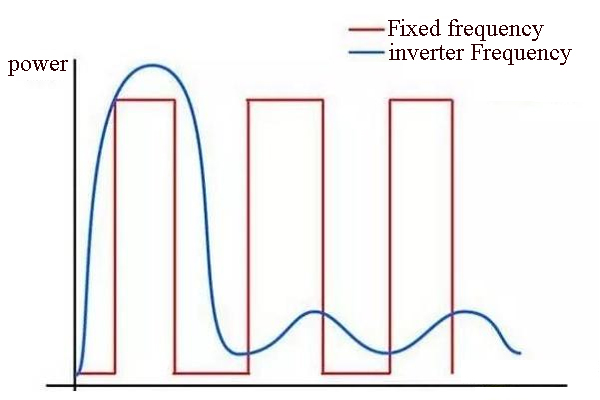

DC inverter chillers1 dynamically adjust compressor speed based on cooling demand, reducing energy consumption. In contrast, fixed-frequency chillers2 operate at a constant speed, leading to energy waste during low-load conditions.

In this article, we will explore the differences between these two types of chillers and explain why DC inverter chillers1 are a superior choice for energy efficiency3.

What is the DC Inverter Chiller?

DC inverter chillers use advanced variable-speed compressor technology to adjust cooling output dynamically. Unlike traditional chillers that operate at a fixed speed, inverter chillers continuously modulate their performance to match real-time cooling requirements.

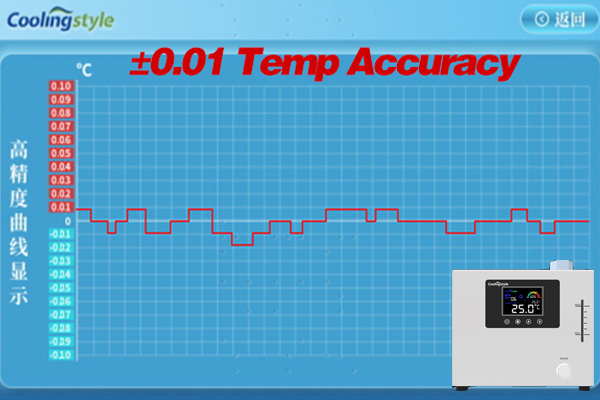

DC inverter chillers use variable-speed compressors4 that adjust cooling power based on demand, providing precise temperature control5 and significantly reducing energy waste.

Key Features of DC Inverter Chillers:

-

Variable-Speed Operation: The compressor speed changes based on real-time cooling needs.

-

Energy Efficiency: By reducing unnecessary energy consumption, these chillers save power.

-

Precise Temperature Control: The system maintains a stable temperature with minimal fluctuations.

-

Reduced Wear and Tear: Smooth start-up and operation extend the lifespan of components.

-

Lower Operating Costs: Efficient energy use results in reduced electricity bills.

What is the Fixed-Frequency Chiller?

Fixed-frequency chillers2 are traditional cooling systems that operate at a constant compressor speed, regardless of cooling demand. They turn on and off as needed, creating fluctuations in energy use and temperature control.

Fixed-frequency chillers2 run at a constant speed, switching on and off to maintain temperature, which leads to higher energy consumption and temperature fluctuations.

Key Features of Fixed-Frequency Chillers:

-

On/Off Cycling: The compressor turns on at full power and shuts off when the set temperature is reached.

-

Energy Inefficiency6: Frequent stopping and starting cause higher power consumption.

-

Temperature Fluctuations7: The system cannot precisely match cooling demand.

-

Shorter Equipment Lifespan: The frequent start-stop operation leads to faster wear.

-

Higher Operational Costs: Increased power usage results in higher energy bills.

What’s the Difference Between DC Inverter Chillers and Fixed-Frequency Chillers?

DC inverter chillers and fixed-frequency chillers differ in their working principles, energy efficiency, and maintenance costs. The table below highlights the key differences:

| Feature | DC Inverter Chiller | Fixed-Frequency Chiller |

|---|---|---|

| Compressor Type | Variable-speed compressor | Constant-speed compressor |

| Energy Efficiency3 | High – adjusts power use dynamically | Low – operates at fixed power |

| Temperature Control8 | Precise and stable | Prone to fluctuations |

| Noise Levels | Low – operates smoothly | High – frequent on/off cycles |

| Lifespan | Longer due to reduced wear | Shorter due to frequent stopping/starting |

| Operational Cost9 | Lower – optimized energy use | Higher – inefficient power consumption |

DC inverter chillers offer significant advantages in terms of energy efficiency, cost savings, and system longevity compared to fixed-frequency chillers.

How DC Inverter Chillers Improve Energy Efficiency Compared to Fixed-Frequency Chillers?

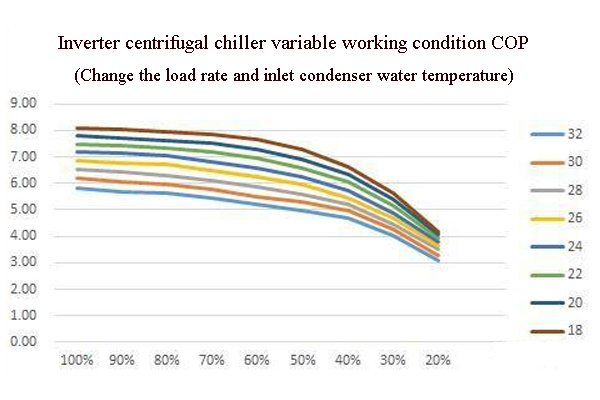

DC inverter chillers1 achieve superior energy efficiency3 through their ability to precisely match cooling output to demand. This is accomplished through several key factors:

1. Variable Speed Operation

DC inverter chillers1 continuously adjust compressor speed based on real-time cooling demand. This eliminates the need for frequent on/off cycling, which reduces power surges and saves energy.

Example: A manufacturing plant using a fixed-frequency chiller may experience energy spikes when the system starts up, while a DC inverter chiller smoothly adjusts cooling output, reducing energy consumption.

2. Reduced Power Waste

Fixed-frequency chillers often run at full capacity even when only partial cooling is needed, wasting energy. In contrast, inverter chillers modulate power usage, optimizing efficiency.

Example: In laser cooling applications, precise temperature control is required. A DC inverter chiller dynamically adjusts cooling levels to match the laser’s workload, preventing unnecessary energy use【10】.

3. Improved Temperature Stability

DC inverter chillers1 maintain a steady temperature without fluctuations. Fixed-frequency chillers tend to overshoot or undershoot the target temperature due to abrupt compressor cycling.

Example: In medical cooling applications, even small temperature deviations can affect performance. DC inverter chillers1 ensure high-precision temperature control, ideal for sensitive applications【10】.

4. Lower Operating Costs

By optimizing energy use, DC inverter chillers1 significantly reduce electricity costs. They also experience less wear and tear, leading to lower maintenance expenses.

Example: A company using DC inverter chillers1 for industrial cooling can see a 30-40% reduction in energy bills compared to traditional fixed-frequency chillers2.

5. Longer Equipment Lifespan

The smooth operation of DC inverter chillers1 reduces stress on components, extending the system’s life and lowering repair costs.

Example: In high-precision manufacturing, equipment longevity is critical. DC inverter chillers1 ensure stable performance over time, reducing downtime and maintenance costs【10】.

Conclusion

DC inverter chillers1 outperform fixed-frequency chillers in energy efficiency3, temperature stability, and cost savings10. Their ability to dynamically adjust cooling output ensures optimal performance, making them an excellent choice for businesses seeking to reduce energy consumption and improve operational efficiency.

-

Explore how DC inverter chillers adapt to cooling demands, leading to significant energy savings and reduced costs. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the limitations of fixed-frequency chillers and why they may not be the best choice for modern cooling needs. ↩ ↩ ↩ ↩ ↩

-

Learn about the advantages of energy efficiency in cooling systems and how it impacts operational costs and the environment. ↩ ↩ ↩ ↩

-

Understanding variable-speed compressors can enhance your knowledge of energy-efficient cooling solutions. ↩

-

Learning about precise temperature control can lead to better comfort and efficiency in your cooling systems. ↩

-

Exploring the effects of energy inefficiency can provide insights into optimizing cooling systems for better performance. ↩

-

Learning about the causes of temperature fluctuations can help in selecting the right cooling technology for stability. ↩

-

Exploring temperature control differences can enhance your knowledge of HVAC systems, ensuring optimal comfort and performance. ↩

-

Learning about operational costs can guide you in selecting the most economical and efficient chiller for your needs. ↩

-

Learn about the financial benefits of DC inverter chillers and how they can lead to significant cost reductions for your business. ↩