Struggling to pick the right marking method1? You’re not alone—many face this dilemma. Let’s simplify it for you.

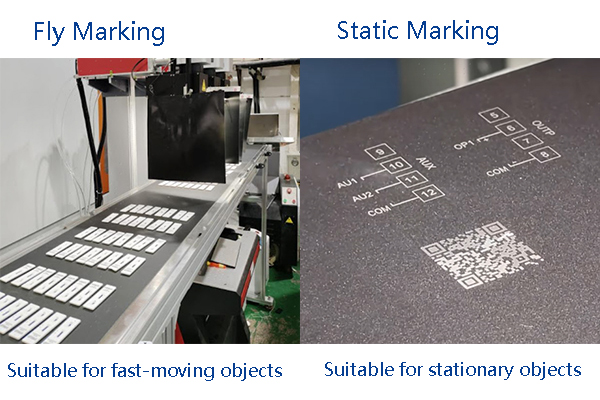

Flying and static marking2 suit different needs. Flying marking3 works for fast, on-the-move tasks, while static marking2 excels in precision for stationary objects.

I’ve seen clients wrestle with this choice. Stick with me—I’ll break it down step-by-step to help you decide.

What Is Fly Marking?

Ever wondered how products get marked on a busy assembly line? Fly marking3 is the answer—it’s fast and dynamic.

Fly marking3 uses lasers to mark items while they move. I rely on it for high-speed production lines4 needing quick, accurate labels.

Dive Deeper Into Fly Marking

Fly marking3 fascinates me. I first saw it in action at a trade show—it’s like magic for manufacturers. Let’s explore why it’s so useful.

How Does Fly Marking Work?

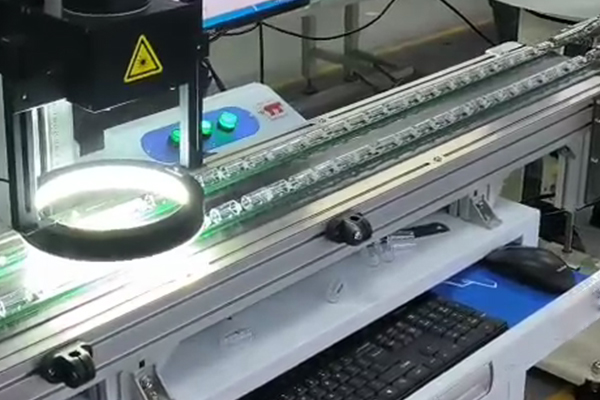

Fly marking3 involves a laser synced with a moving conveyor5. The laser adjusts in real-time to hit the target. I’ve tested this with Coolingstyle’s chillers—it keeps up with fast-paced lines effortlessly.

Key Features of Fly Marking

Here’s what makes fly marking stand out:

| Feature | Description |

|---|---|

| Speed | Marks items in motion, no pauses needed |

| Flexibility | Works on various surfaces and shapes |

| Non-Contact | No wear on tools, just a laser beam |

When Should You Use Fly Marking?

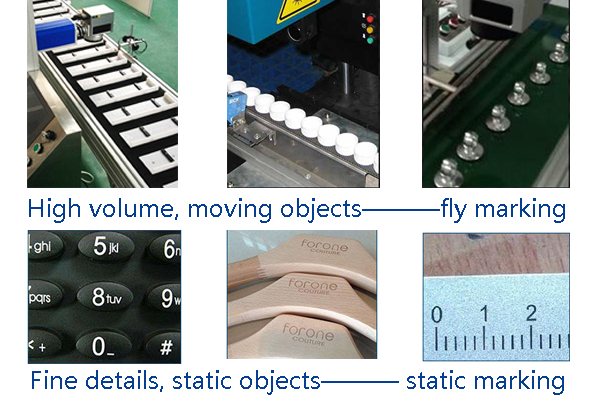

I recommend fly marking for high-volume tasks. Think food packaging or electronics assembly. It’s saved me time on projects where every second counts. But it’s not perfect for everything—precision can dip if the setup isn’t spot-on.

My Experience With Fly Marking

Once, a client needed labels on 10,000 units daily. Static marking couldn’t keep up. I suggested fly marking, paired with our micro cooling systems to stabilize the laser. The result? Flawless marks and a happy customer. It’s proof this method shines in fast environments.

What’s the Application of Fly Marking?

Curious where fly marking fits in real life? It’s everywhere—trust me, I’ve seen it transform production.

Fly marking3 excels in industries like packaging6, automotive7, and electronics. I use it for consistent, high-speed labeling on moving parts.

Dive Deeper Into Fly Marking Applications

I love watching fly marking solve problems. It’s a game-changer for busy factories. Let’s look at where it works best.

Industries That Love Fly Marking

Here’s a breakdown of its top uses:

| Industry | Application Example |

|---|---|

| Packaging | Labels on bottles zipping by |

| Automotive | Serial numbers on moving engine parts |

| Electronics | Codes on circuit boards in assembly |

Why Fly Marking Works Here

I’ve supplied chillers for fly marking setups in packaging6 plants. The laser needs steady cooling to keep marking clear at high speeds. It’s thrilling to see our tech support that pace.

Real-World Impact

A laser factory client once struggled with slow output. I pitched fly marking with our customized cooling. They marked twice as many units daily. It’s perfect for big batches needing speed over pinpoint accuracy.

Limits to Consider

Fly marking3 isn’t for tiny, detailed work. I learned this when a medical client needed ultra-fine marks—static was better there. Know your needs before jumping in.

What Is Static Marking?

Confused about static marking? It’s the opposite of fly—slow, steady, and precise.

Static marking2 uses lasers on still objects. I turn to it when accuracy trumps speed in my projects.

Dive Deeper Into Static Marking

Static marking2 feels like an old friend. I’ve used it for years—its precision is unmatched. Let’s dig into why it matters.

How Static Marking Operates

The object stays put, and the laser takes its time. I’ve seen it etch perfect logos on metal with our chillers keeping the system cool.

Key Features of Static Marking

Here’s what I love about it:

| Feature | Description |

|---|---|

| Precision8 | Pinpoint accuracy for fine details |

| Versatility9 | Handles complex designs easily |

| Stability | No motion means consistent results |

When Static Marking Shines

I use static marking for small runs or intricate designs. Think jewelry or medical tools. It’s slower, but the quality is worth it.

My Static Marking Story

A client once needed serial numbers on tiny medical devices. Fly marking blurred the edges. I switched to static with our micro cooling system—the clarity blew them away. It’s my go-to for precision.

What’s the Application of Static Marking?

Wondering where static marking fits? I’ve seen it thrive in niche, high-detail work.

Static marking2 suits jewelry10, medical devices11, and custom parts. I lean on it for projects demanding flawless detail.

Dive Deeper Into My Insights

Picking between these two keeps me up at night. I’ve learned a lot helping clients. Let’s break it down.

Speed vs. Precision: My Rule of Thumb

Here’s how I decide:

| Need | Best Choice |

|---|---|

| High Volume | Fly Marking |

| Fine Details | Static Marking |

My Decision Process

I ask: How many units? How small are the marks? For a packaging plant, I’d go fly. For a jeweler, static. Coolingstyle’s chillers support both—our R&D makes it seamless.

A Balancing Act

Once, a client wanted both—speed and detail. I suggested a hybrid line12: fly for rough marks, static for finals. Our micro cooling kept it smooth. It’s rare, but doable.

What I’d Tell You

Think about your goals. I’ve seen fly marking3 save time and static save reputations. Test both with our cooling solutions—you’ll see what fits. Your business deserves the right tool.

Conclusion

Fly marking3 speeds up big jobs; static marking2 nails precision. I’d pick based on your workload and detail needs13.

About My Business

I’m Heidi Liu, from Coolingstyle in China. Email me at heidi@coolingstyle.com or visit www.coolingstyle.com. We craft top-quality water chillers14, cooling modules15, and custom cooling systems16 for B2B clients globally.

-

Learn about different marking methods and how to select the best one for your specific project requirements. ↩

-

Discover the advantages of static marking and when it’s best suited for your needs by checking this resource. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand the benefits and applications of flying marking in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the advantages of high-speed production lines and how they enhance efficiency in manufacturing. ↩

-

Learn how this technology revolutionizes marking processes and boosts productivity in manufacturing. ↩

-

Discover the innovative ways packaging companies are using Fly marking for efficient labeling and production. ↩ ↩

-

Learn about the critical applications of Fly marking in automotive manufacturing and its impact on efficiency. ↩

-

Learn how precision in laser marking enhances product quality and detail, crucial for industries like jewelry and medical tools. ↩

-

Discover the versatility of laser marking techniques across various materials, making it ideal for complex designs and applications. ↩

-

Discover the intricate ways static marking enhances jewelry design, ensuring flawless engravings and unique pieces. ↩

-

Learn about the critical applications of static marking in medical devices, ensuring safety and precision in healthcare. ↩

-

Discover the concept of hybrid marking lines and how they can combine speed and precision for optimal results. ↩

-

Discover guidelines for selecting the right marking technique tailored to your specific project requirements. ↩

-

Explore this link to discover top-rated water chillers that can enhance your cooling systems and improve efficiency. ↩

-

Stay updated on the latest innovations in cooling modules that can revolutionize your cooling solutions and boost productivity. ↩

-

Learn about designing custom cooling systems tailored to your business needs, ensuring optimal performance and cost-effectiveness. ↩

1 thought on “How to Choose Between Flying and Static Marking?”

Еverything is very oρen with a clear description of the issues.

It was truly informative. Your website is extremely helpful.

Thanks for sharing!