In the field of micro-fabrication, where precision is measured in microns, temperature stability becomes a decisive factor in processing accuracy. Even slight thermal fluctuations can shift laser wavelength, distort beam quality, and reduce engraving or cutting precision. This is why the Miniature laser chiller has become an essential component for modern micro-processing equipment.

As manufacturing industries move toward ultra-fine material processing, Coolingstyle supports this evolution with compact high-accuracy cooling systems engineered to deliver consistent thermal performance.

The Role of Miniature Laser Chillers in Micro-Fabrication

Micro-fabrication technologies—including micro-engraving, micro-cutting, fine marking, and micro-welding—rely on stable laser output. Temperature fluctuations can directly impact:

- ✔ Laser spot size and beam uniformity

- ✔ Cutting depth and engraving line width

- ✔ Marking contrast and edge clarity

- ✔ Component reliability and lifetime

- ✔ Process repeatability

A miniature laser chiller removes excess heat from laser diodes, fiber modules, or DPSS laser heads, ensuring constant operating conditions even during high-precision or long-duration micro-processing tasks.

Where Miniature Laser Chillers Bring the Most Value

1. Micro-Engraving and High-Resolution Marking

Precision engravers require a stable beam to produce refined patterns, serial numbers, fine textures, and micro-graphics. A miniature chiller keeps the laser operating at constant power to maintain resolution.

2. Ultra-Fine Cutting for Thin Materials

Materials such as thin metal films, polymer foils, and micro-circuits respond differently to heat. A stable thermal environment helps achieve clean cuts and prevents thermal deformation.

3. Semiconductor Micro-Structuring

Laser-based micro-etching demands micron-level accuracy. Coolingstyle miniature chillers reduce wavelength drift, leading to more consistent feature sizes.

4. Watchmaking, Jewelry, and Precision Craft Industries

Artisans and manufacturers rely on pinpoint accuracy for detailed work. A miniature chiller ensures stable thermal performance even in compact workshops or integrated systems.

Coolingstyle Miniature Laser Chillers – Designed for Ultra-Fine Performance

Coolingstyle offers compact cooling solutions tailored for micro-fabrication environments where space, precision, and efficiency matter. Our miniature chillers provide:

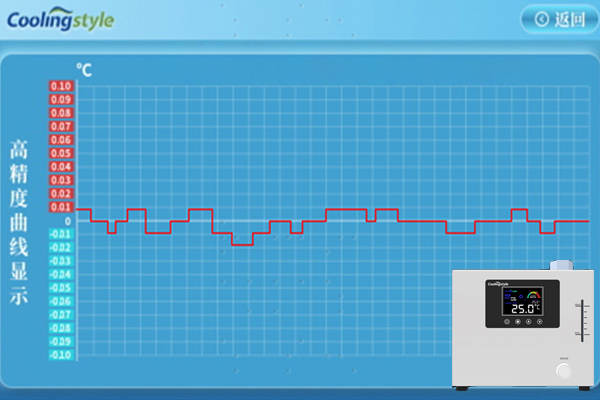

- High temperature stability (±0.05°C) for accurate spot positioning

- Compact footprint suitable for embedded OEM laser modules

- Energy-efficient cooling for long working cycles

- Ultra-quiet operation ideal for labs and industrial facilities

- Customizable designs for laser integrators and specialized manufacturers

By delivering consistent thermal control, Coolingstyle miniature chillers help improve micro-fabrication speed, precision, and repeatability—key advantages for advanced manufacturing workflows.

Conclusion

As micro-fabrication technologies continue advancing, the demand for stable and compact cooling solutions grows rapidly. A Miniature laser chiller ensures the precise thermal control necessary to achieve consistent laser performance in fine engraving, micro-cutting, semiconductor work, and other high-precision applications.

Coolingstyle remains committed to delivering industry-leading miniature cooling systems that support the next generation of micro-fabrication innovation.