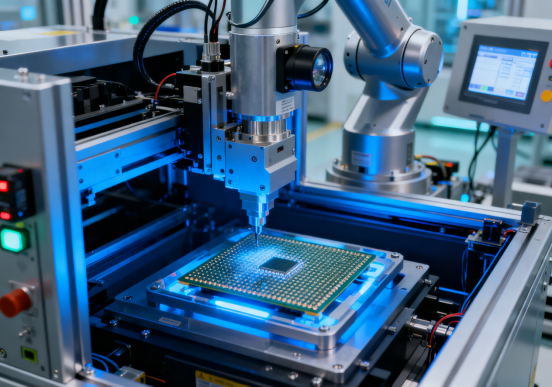

The semiconductor industry demands extreme precision, stable temperature control, and strict process reliability. As chip fabrication technologies continue to advance—shrinking nodes, higher power density, more complex laser processing operations—the importance of efficient thermal management becomes more critical. Among the key innovations supporting this evolution is the Miniature Laser Chiller, a compact yet high-performance cooling device designed to deliver stable temperature regulation for semiconductor laser systems.

Coolingstyle, a global leader in micro-cooling technology, provides highly reliable miniature chillers engineered for sensitive laser applications used throughout semiconductor manufacturing. With precise temperature control, compact design, and industrial-grade reliability, Coolingstyle’s miniature laser chillers help semiconductor equipment maintain peak performance even in demanding production environments.

Why Temperature Control Is Critical in Semiconductor Laser Processes

Laser systems are essential in multiple semiconductor processes, including:

- Wafer cutting and scribing

- Laser annealing and thermal treatment

- Micro-patterning and lithography assistance

- Marking and micro-engraving on wafers or packaging materials

- Precision bonding and welding of micro-components

These processes require laser output stability, low thermal drift, and consistent wavelength behavior. Even small temperature fluctuations—sometimes as minimal as 0.1°C—can lead to:

- Beam quality deviation

- Cutting edge defects

- Inconsistent annealing results

- Misalignment or dimensional inaccuracies

- Product yield reduction

Thus, a stable, compact, and efficient cooling solution like a Miniature Laser Chiller becomes indispensable for modern semiconductor equipment manufacturers.

What Is a Miniature Laser Chiller?

A Miniature Laser Chiller is a small-form-factor cooling device specifically designed to maintain stable temperatures in precision laser systems. Unlike bulky industrial chillers, miniature chillers deliver high-accuracy cooling with a fraction of the size and power consumption.

Key characteristics include:

- Compact footprint suitable for small or integrated semiconductor tools

- High-precision temperature control (±0.05°C achievable with Coolingstyle)

- Low vibration and low noise operation

- High reliability for continuous 24/7 manufacturing

- Customizable cooling capacity and configuration

For semiconductor OEMs developing next-generation systems, these advantages make miniature chillers a perfect fit for integration or external support.

Applications of Miniature Laser Chillers in Semiconductor Manufacturing

1. Wafer Cutting and Dicing Lasers

Modern semiconductor wafers—especially SiC and GaN—are increasingly difficult to cut. High-power UV and IR lasers generate substantial heat, requiring stable cooling to avoid thermal drift. A Miniature Laser Chiller keeps temperatures constant, ensuring:

- Uniform cutting depth

- Reduced micro-cracks

- Improved edge quality

- Higher wafer yield

2. Laser Annealing and Recrystallization

Temperature fluctuations directly affect laser intensity during annealing. Miniature chillers provide precise cooling to maintain laser wavelength stability, essential for achieving consistent electrical properties in semiconductor materials.

3. Lithography Laser Stabilization

Excimer, CO₂, and diode lasers used in lithography demand meticulous thermal control. Coolingstyle miniature chillers maintain ultra-stable cooling that improves lithography accuracy and reduces pattern distortion.

4. Bonding and Packaging Lasers

Advanced packaging processes—such as micro-welding, micro-cutting, and selective soldering—use laser systems that rely on miniature chillers to avoid overheating sensitive micro-components.

5. Semiconductor Inspection and Metrology Equipment

Optical inspection lasers generate heat even at low power. Miniature chillers ensure:

- Stable wavelength for measurement accuracy

- Low noise operation for precision environments

- Long-term system stability

Why Coolingstyle Miniature Laser Chillers Are Ideal for Semiconductor Production

Coolingstyle’s miniature laser chillers are engineered specifically for industries that demand uncompromising accuracy. The following advantages make them highly suitable for semiconductor tools:

1. Ultra-High Temperature Precision (±0.05°C)

This is essential for laser wavelength control, beam shaping stability, and semiconductor process repeatability.

2. Compact, Lightweight, and Easy to Integrate

Coolingstyle designs micro chillers with small footprints ideal for laser modules, mobile units, desktop semiconductor tools, and OEM integration.

3. Energy-Efficient and Environmentally Friendly

Compared with traditional chillers, Coolingstyle’s miniature chiller consumes far less power while maintaining high cooling efficiency.

4. Industrial-Grade Reliability for 24/7 Operation

Semiconductor fabs operate continuously, and Coolingstyle chillers are built with long-life components suitable for round-the-clock use.

5. Customizable Solutions

Coolingstyle supports OEM and ODM requirements, offering customization such as:

- Cooling capacity

- Mounting size

- Control system interface

- Fluid compatibility

- Integrated pump and sensor options

This makes Coolingstyle an ideal partner for semiconductor equipment manufacturers developing specialized laser systems.

How Miniature Laser Chillers Improve Semiconductor Production Efficiency

Integrating a high-precision cooling system enhances multiple aspects of chip manufacturing:

- Better Yield: Reduced defects and more consistent laser behavior.

- Longer Laser Life: Stable temperatures reduce thermal stress and degradation.

- Higher Process Precision: Improved cutting accuracy, better annealing uniformity, and enhanced lithography performance.

- Reduced Downtime: Compact chillers require minimal maintenance.

- Lower Energy Cost: Miniature chillers use less electricity than conventional units.

Ultimately, manufacturers benefit from more stable production lines and lower operating costs.

Coolingstyle — Your Professional Partner in Miniature Laser Cooling

With extensive experience in micro-cooling R&D and production, Coolingstyle provides high-precision miniature chillers for global semiconductor companies. Whether you develop wafer dicing machines, annealing tools, lithography support lasers, or micro-processing equipment, Coolingstyle can deliver reliable thermal management solutions tailored to your needs.

Our miniature laser chillers are adopted in semiconductor, medical, laser processing, and scientific instruments worldwide—trusted for their precision, reliability, and compact engineering.

Coolingstyle’s mission is to help semiconductor manufacturers achieve higher accuracy, greater efficiency, and long-term operational stability.

Conclusion

As semiconductor processes evolve toward higher precision and greater complexity, reliable thermal control becomes more critical than ever. A Miniature Laser Chiller is no longer optional—it is a fundamental component for ensuring laser stability, improving manufacturing yield, and protecting sensitive micro-components.

With unmatched temperature precision, compact design, and industrial-grade performance, Coolingstyle miniature chillers empower semiconductor manufacturers to build next-generation production systems with confidence.

For OEM customization or integration support, Coolingstyle offers engineering assistance and high-performance chiller solutions designed specifically for semiconductor laser applications.