In the semiconductor manufacturing industry, temperature stability is critical for accuracy, yield, and equipment lifespan. A semiconductor chiller from Coolingstyle delivers ultra-precise temperature control to ensure process consistency and equipment reliability. As a professional micro cooling solution manufacturer, Coolingstyle specializes in customized semiconductor chillers, mini cooling units, and refrigeration modules with temperature precision up to ±0.05 °C.

Why Temperature Control Matters in Semiconductor Manufacturing

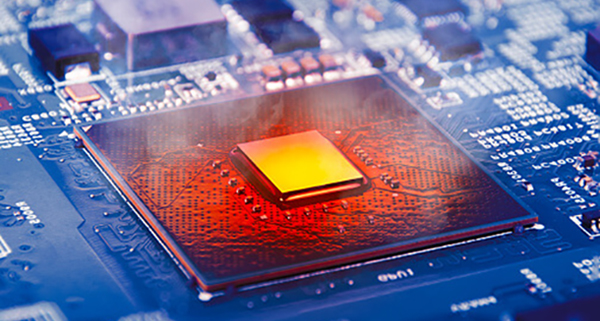

Semiconductor processes such as wafer lithography, laser annealing, etching, and precision bonding are extremely sensitive to thermal variations. Even a temperature drift of 0.1 °C can cause alignment errors or quality inconsistencies in microelectronic devices. That’s why a semiconductor-specific chiller is essential — it keeps the temperature stable, protecting critical tools and improving yield rates.

- Maintains precise temperature for wafers and optical components

- Prevents equipment overheating during continuous operation

- Improves process stability and reduces product defects

- Extends the service life of lasers, power electronics, and vacuum systems

Coolingstyle Semiconductor Chillers – High Precision Meets Compact Design

Coolingstyle designs and manufactures compact semiconductor chillers and micro cooling systems that deliver precision, reliability, and efficiency. With over a decade of experience in micro refrigeration technology, we integrate advanced PID temperature control, low-vibration compressors, and efficient heat exchangers — all within a small footprint.

Core Features:

- Ultra-high precision control – temperature accuracy up to ±0.05 °C

- Compact & modular structure – ideal for semiconductor tools with limited space

- Low noise & vibration – suitable for cleanroom environments

- Custom-built systems – tailored to wafer, laser, or vacuum process cooling

- Industrial-grade reliability – continuous 24/7 operation with stable performance

Applications of Semiconductor Chillers

Our semiconductor chillers are widely used in high-precision industrial and research environments, including:

- Semiconductor wafer processing and testing

- Laser alignment and lithography systems

- Plasma etching and ion implantation machines

- Vacuum coating and optical thin-film equipment

- Semiconductor packaging and bonding tools

Each Coolingstyle chiller is engineered to provide consistent temperature control even in complex, multi-step semiconductor fabrication processes.

Why Choose Coolingstyle for Semiconductor Cooling?

Unlike typical chiller suppliers, Coolingstyle is a source manufacturer specializing in micro cooling and thermal management systems. We offer end-to-end customization — from semiconductor chiller design to module integration — ensuring optimal thermal precision for your specific process.

Coolingstyle Advantages:

- ✅ ±0.05 °C precision temperature stability

- ✅ OEM / ODM customization for semiconductor tools

- ✅ Compact, cleanroom-ready design

- ✅ Factory-direct production and technical support

- ✅ Proven reliability in industrial and research environments

Our semiconductor chillers have been successfully applied in microelectronics, photonics, and laser-based semiconductor systems worldwide, helping customers achieve superior performance and production stability.

Custom Semiconductor Cooling Systems

Every semiconductor tool requires a unique cooling approach — from high-power laser modules to sensitive wafer stages. Coolingstyle provides custom semiconductor chillers designed for your exact process specifications.

We can design and manufacture:

- Integrated micro refrigeration modules for OEM systems

- Closed-loop semiconductor cooling units with intelligent control

- Compact chillers for limited-space or portable systems

- Smart monitoring and communication interfaces (RS485 / Modbus)

Our R&D team works closely with semiconductor equipment manufacturers to develop scalable, energy-efficient, and high-precision cooling systems suitable for advanced fabrication environments.

Conclusion: Coolingstyle – Precision Cooling for the Semiconductor Era

A Coolingstyle semiconductor chiller provides the stability, compactness, and accuracy essential for modern semiconductor manufacturing. With precision temperature control up to ±0.05 °C and customizable configurations, Coolingstyle empowers high-end equipment with superior thermal reliability and operational efficiency.

If you are looking for a semiconductor chiller or micro cooling system for your next-generation equipment, contact Coolingstyle today — your trusted partner in advanced micro cooling solutions.

Frequently Asked Questions (FAQ)

Q1: What makes a semiconductor chiller different from a standard industrial chiller?

A semiconductor chiller provides higher temperature precision, cleaner operation, and lower vibration — all critical for sensitive processes like wafer fabrication and laser alignment.

Q2: Can Coolingstyle design a custom semiconductor chiller for my equipment?

Yes. Coolingstyle offers full OEM/ODM customization, from system structure to cooling capacity, ensuring perfect integration with your semiconductor tools.

Q3: What temperature control accuracy does Coolingstyle provide?

Our semiconductor chillers achieve up to ±0.05 °C precision, ideal for ultra-stable environments and high-end applications.