Femtosecond lasers, known for their extraordinary precision and ultra-short pulse durations, are revolutionizing industries from medical surgery to advanced manufacturing. These lasers can produce pulses lasting just a few quadrillionths of a second, enabling incredibly fine and controlled material processing. However, achieving and maintaining such precision necessitates meticulous temperature control. This article delves into the critical role temperature control plays in optimizing the performance of femtosecond lasers.

The Importance of Temperature Control in Femtosecond Lasers

Stability and Consistency

Femtosecond lasers require a stable operating environment to maintain their precision. Temperature fluctuations can cause variations in the laser’s output, affecting pulse duration, beam quality, and overall performance. Precise temperature control ensures that the laser operates consistently, maintaining its peak performance and delivering reliable results in applications such as micromachining, medical procedures, and scientific research.

Beam Quality

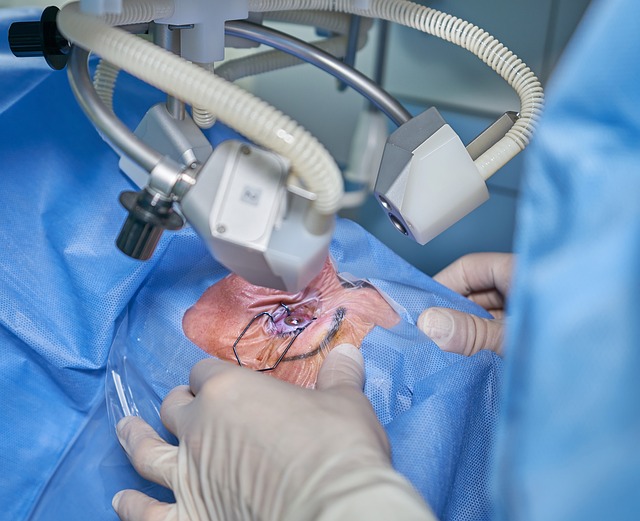

Temperature variations can lead to thermal lensing and beam distortion, degrading the quality of the laser beam. By maintaining a stable temperature, these distortions are minimized, resulting in a cleaner, more focused beam. This is crucial for applications requiring high precision and accuracy, such as photolithography in semiconductor manufacturing or delicate eye surgeries.

Longevity and Reliability

Components within femtosecond lasers, including optics and gain media, are sensitive to temperature changes. Excessive heat can cause thermal stress, leading to premature failure or reduced lifespan of these components. Effective temperature control not only enhances the performance but also extends the longevity and reliability of the laser system, reducing maintenance costs and downtime.

Mechanisms of Temperature Control

Water Cooling Systems

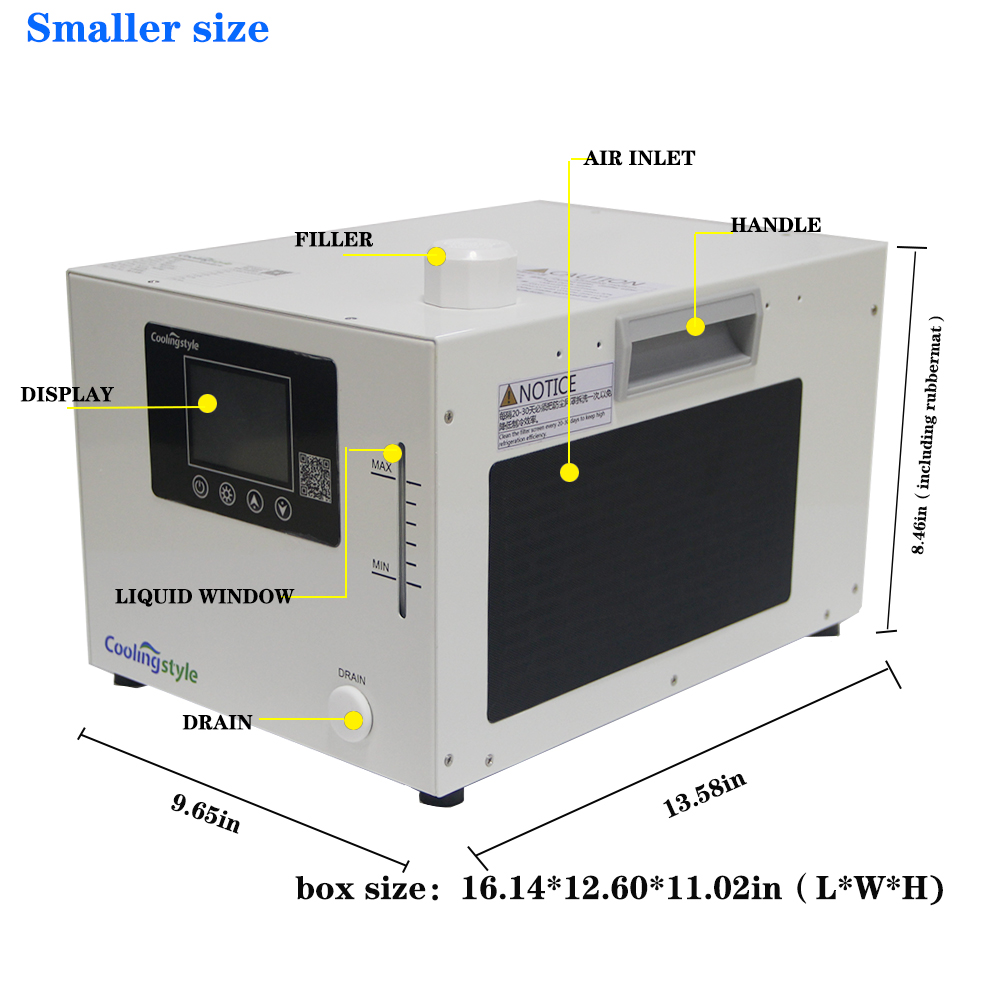

Water cooling is one of the most effective methods for managing the temperature of femtosecond lasers. High-precision water chillers are employed to regulate the temperature of critical components. One standout product in this category is the CoolingStyle water chiller, which achieves precise temperature control within ±0.1°C. This level of precision is essential for ensuring that femtosecond lasers operate at optimal conditions, contributing significantly to both the performance and reliability of the laser systems. Whether in research, medical fields, or high-precision manufacturing, the CoolingStyle water chiller provides a stable and reliable temperature environment, safeguarding your precise operations. Visit

Air Cooling Systems

Air cooling systems, though less precise than water cooling, are also used in some femtosecond laser setups. These systems rely on fans and heat sinks to dissipate heat from the laser components. While easier to implement and maintain, air cooling systems are more susceptible to environmental temperature changes and may not provide the same level of precision as water cooling systems.

Case Studies: Temperature Control in Action

Medical Applications

In medical applications, such as LASIK eye surgery, the precision of femtosecond lasers is paramount. Temperature fluctuations can alter the laser’s performance, potentially compromising the safety and efficacy of the procedure. Implementing high-precision temperature control systems ensures the laser operates within optimal parameters, providing consistent and accurate results for delicate surgeries.

Industrial Manufacturing

In the realm of industrial manufacturing, femtosecond lasers are used for micromachining and creating intricate features on materials. Temperature control systems ensure the laser beam remains stable and precise, enabling the production of high-quality components with minimal defects. This level of precision is essential for industries such as aerospace, electronics, and automotive manufacturing, where even the smallest deviations can lead to significant issues.

Conclusion: The Future of Femtosecond Lasers and Temperature Control

As femtosecond lasers continue to push the boundaries of precision and performance, the importance of effective temperature control cannot be overstated. Advances in cooling technology will play a crucial role in unlocking the full potential of these lasers, enabling their use in increasingly demanding applications. Whether in the operating room, on the manufacturing floor, or in cutting-edge research laboratories, precise temperature control will remain a cornerstone of femtosecond laser technology, ensuring unparalleled performance and reliability.

By understanding and implementing advanced temperature control systems, industries can harness the true power of femtosecond lasers, driving innovation and achieving new levels of precision and efficiency.

Reference: