In the field of high-precision refrigeration, the size and heat dissipation performance of equipment are often a contradiction. How to achieve efficient heat dissipation in a limited space is a challenge faced by many industries. Coolingstyle, with its leading temperature control technology, has successfully adopted microchannel condensers1 in numerous customized refrigeration systems with strict size requirements, creating more compact and efficient solutions.

The application of microchannel condensers1 enables Coolingstyle to provide customers with more compact, lighter, and more energy-efficient customized refrigeration products2, meeting the needs of high-end fields such as laser equipment, medical instruments, and industrial production.

So, what are the unique advantages of microchannel condensers1? How do they help Coolingstyle achieve smaller size and higher efficiency in customized refrigeration systems? Let’s delve deeper.

Why is the heat exchange efficiency3 of a microchannel condenser higher?

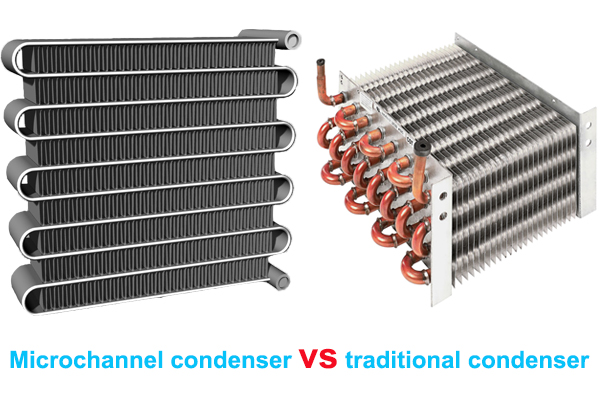

In refrigeration systems, heat exchange efficiency3 directly determines cooling capacity4. Traditional condensers use a copper tube fin design, with a relatively long refrigerant flow path and limited heat exchange efficiency3. Microchannel condensers completely change this model.

Microchannel condensers increase the contact area between the refrigerant and the tube wall, achieving a faster heat exchange rate and thus improving overall heat exchange efficiency3.

How do microchannel condensers1 optimize heat exchange?

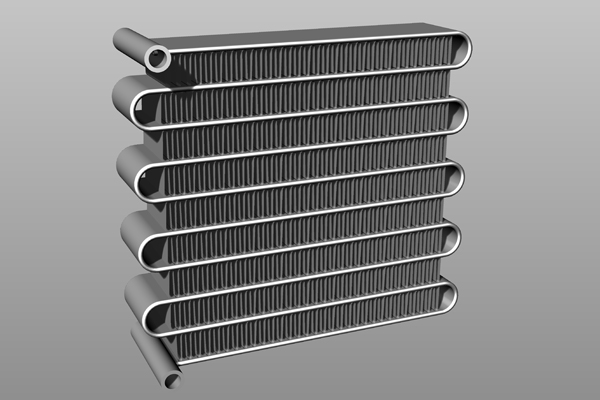

1.Ultra-thin microchannel structure:

The use of multiple microchannels significantly increases the contact area between the refrigerant and the tube wall, improving heat exchange efficiency3.

2.Uniform Condensation Process

Traditional heat exchangers have a large temperature gradient, while the compact design of microchannel condensers1 ensures more uniform heat dissipation5, improving the stability of the condensation process.

3.Higher Heat Flux Density

Microchannel technology can withstand higher heat flux, enabling condensers of the same volume to have stronger heat exchange capabilities.

How do microchannel condensers1 reduce product size and weight?

In many high-end devices, small size and light weight6 are crucial requirements, such as portable cooling equipment, precision instruments, or industrial applications with space constraints. Traditional copper tube heat exchangers are difficult to meet these needs due to their large size and weight, while microchannel condensers1 offer a superior solution.

Compared with traditional copper tube fin condensers, microchannel condensers1 can reduce weight by more than 50% and volume by more than 30%.

Compactness Advantages of Microchannel Condenser1s

| Feature | Traditional Condenser | Microchannel Condenser |

|---|---|---|

| Volume | Large | Small |

| Weight | Heavy | Light |

| Material | Copper-aluminum combination | Pure aluminum |

| Heat transfer efficiency | Moderate | High |

| Applicable scenarios | Standard refrigeration | Customized small-scale refrigeration |

Thanks to the lightweight nature of microchannel condensers, Coolingstyle can help customers create ultra-compact customized products to meet the precise cooling needs of fields such as high-end laser equipment, military electronics, and medical instruments.

How do microchannel condensers1 reduce refrigerant usage?

The amount of refrigerant charge7d directly impacts a device’s environmental friendliness, cost, and safety. Traditional condensers, due to their larger pipes, require a larger amount of refrigerant. Microchannel condensers, however, significantly reduce refrigerant usage thanks to their optimized design.

The smaller internal channels in microchannel condensers1 reduce refrigerant charge7 by 30%-50%, meeting the needs of environmentally friendly refrigerants8 (such as R32 and R290).

Why is reducing refrigerant use important?

1.More Environmentally Friendly

Using less refrigerant means lower carbon emissions and compliance with global environmental regulations9.

Reduced refrigerant usage leads to lower maintenance and operating costs due to the high price of refrigerants.

3.Safer

Refrigeration systems with lower charge amounts are safer during transportation, installation, and use, reducing the risk of leaks.

How can the corrosion resistance of microchannel condensers11 be enhanced?

Refrigeration systems often operate in harsh environments for extended periods, such as high humidity, high salinity, or industrial chemical environments. Insufficient corrosion resistance12 of the condenser can lead to performance degradation and even affect the lifespan of the equipment.

Microchannel condensers adopt an all-aluminum structure, completely avoiding the galvanic corrosion problems of traditional copper-aluminum combined heat exchangers, and can enhance corrosion resistance12 through special coatings.

How can Coolingstyle improve its corrosion resistance12?

1.All-aluminum material:

Completely eliminates the risk of galvanic corrosion caused by copper-aluminum junctions, increasing the service life of the equipment.

2.Special anti-corrosion coating13:

An additional anti-corrosion coating13 further enhances the durability of the condenser in harsh environments.

3.Strict weather resistance testing:

Coolingstyle conducts high-temperature, high-humidity, and salt-spray tests on all microchannel condensers1 to ensure their long-term stability in various application scenarios.

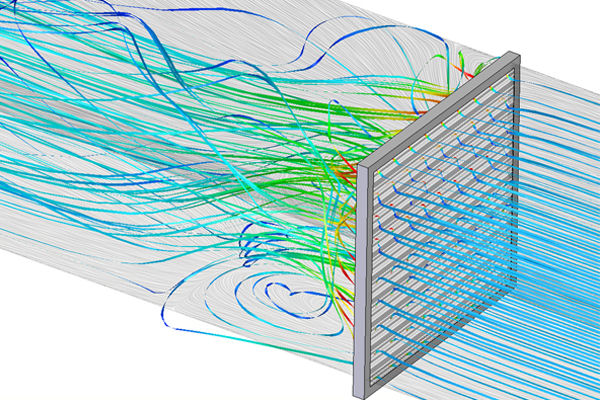

How do microchannel condenser1s improve the coefficient of performance (COP)14?

The coefficient of performance (COP)14 is a key indicator for measuring the efficiency of a refrigeration system. The optimized airflow design of the microchannel condenser1 leads to lower cooling air resistance, thus reducing fan energy consumption and improving overall energy efficiency.

The microchannel condenser1 reduces air resistance by 30% compared to traditional heat exchangers, and improves the coefficient of performance (COP)14 by more than 15%.

How to achieve a higher COP?

The ultra-thin fins and micro-channel structure minimize airflow resistance, reducing fan power consumption.

2.Higher Efficiency Heat Exchange16:

The high heat transfer capacity of the micro-channels enables faster condensation, reducing the compressor workload.

3.Intelligent Control Optimization17:

Combined with Coolingstyle’s variable frequency control algorithm, the condenser’s operating status is further optimized, ensuring the system maintains peak energy efficiency.

Typical Applications of Microchannel Condensers

Coolingstyle’s microchannel condensers are widely used in customer-designed refrigeration equipment18, especially in applications with stringent requirements for volume, weight, and energy efficiency19:

- Laser Equipment Cooling20 (Compact Laser Chiller)

- Military Electronics Cooling (Miniature Radar Cooling System)

- Medical Equipment Cooling (Portable MRI/CT Cooling System)

- Industrial Refrigeration (High-Precision Chiller Unit)

- Data Center Cooling (Liquid-Cooled Server)

Conclusion

Microchannel condenser is one of the core technologies of Coolingstyle in building small, efficient, and customized refrigeration systems. With features such as high heat transfer efficiency21, compact and lightweight design22, low refrigerant charge, high corrosion resistance, and high energy efficiency ratio23, Coolingstyle can provide customers with more advanced customized cooling solutions to meet the heat dissipation needs of various high-end precision equipment.

In the future, Coolingstyle will continue to innovate and promote the development of microchannel condenser technology in a wider range of applications, helping customers achieve smaller and more energy-efficient cooling systems.

-

Explore the advantages of microchannel condensers to understand how they enhance efficiency and compactness in refrigeration systems. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the features that contribute to energy efficiency in customized refrigeration products, crucial for modern applications. ↩

-

Understanding the factors that affect heat exchange efficiency can help optimize refrigeration systems for better performance. ↩ ↩ ↩ ↩ ↩

-

Learning about the relationship between cooling capacity and heat exchange efficiency can improve your understanding of refrigeration performance. ↩

-

Discover the significance of uniform heat dissipation in optimizing the performance of heat exchangers and ensuring stability. ↩

-

Understanding the advantages of small size and light weight can help you appreciate the innovations in cooling technology. ↩

-

Understanding refrigerant charge is crucial for optimizing HVAC performance and ensuring environmental compliance. ↩ ↩

-

Discover the latest environmentally friendly refrigerants and their benefits for sustainable cooling solutions. ↩

-

Understanding these regulations is crucial for compliance and promoting environmentally friendly practices in refrigeration. ↩

-

Exploring this resource will provide insights into how reducing refrigerant use can significantly cut costs in refrigeration systems. ↩

-

This link will offer valuable information on enhancing the durability and efficiency of microchannel condensers in harsh environments. ↩

-

Explore this link to discover effective strategies and technologies that enhance corrosion resistance in refrigeration systems, ensuring longevity and performance. ↩ ↩ ↩

-

This resource will provide insights into how anti-corrosion coatings function and their importance in extending the lifespan of refrigeration equipment. ↩ ↩

-

Understanding COP is crucial for evaluating refrigeration efficiency. Explore this link to learn more about its significance and applications. ↩ ↩ ↩

-

Understanding the impact of air resistance can help you optimize your cooling systems for better efficiency and lower costs. ↩

-

Exploring this resource will provide insights into how efficient heat exchange can enhance energy savings and system performance. ↩

-

This link will explain how intelligent control can maximize energy efficiency and improve system reliability in HVAC applications. ↩

-

Explore this link to understand how custom refrigeration solutions can enhance efficiency and meet specific needs in various industries. ↩

-

Discover the critical applications that demand high performance in cooling systems, ensuring optimal operation in challenging environments. ↩

-

Learn about cutting-edge technologies in laser cooling that improve performance and reliability in high-demand applications. ↩

-

Understanding high heat transfer efficiency can help you appreciate its role in energy savings and system performance. ↩

-

Exploring this topic reveals how design impacts efficiency and usability in modern cooling solutions. ↩

-

Learning about energy efficiency ratios can guide you in choosing more sustainable and cost-effective cooling options. ↩