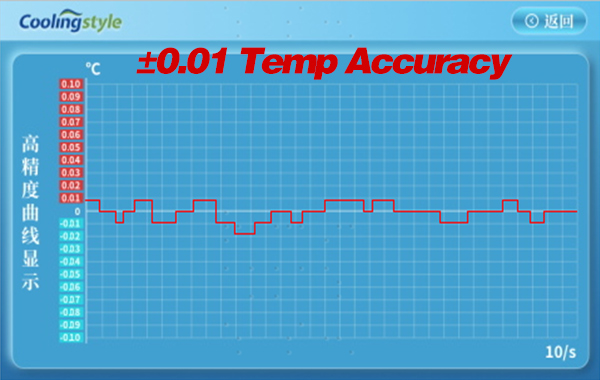

Precise Temperature Control to 0.01℃

Coolingstyle’s industrial chillers are engineered to deliver high-precision cooling, ensuring your operations run smoothly and efficiently. Our chillers offer reliable temperature control with a tolerance as tight as ±0.01℃, making them ideal for applications that demand exact thermal management.

Reliable Cooling Solutions for Your Laser Device

Coolingstyle’s industrial chillers are specifically designed to meet the demanding cooling needs from 400W to 2700W. Our chillers provide reliable and precise temperature control, ensuring your laser devices operate at peak efficiency, even under continuous operation.

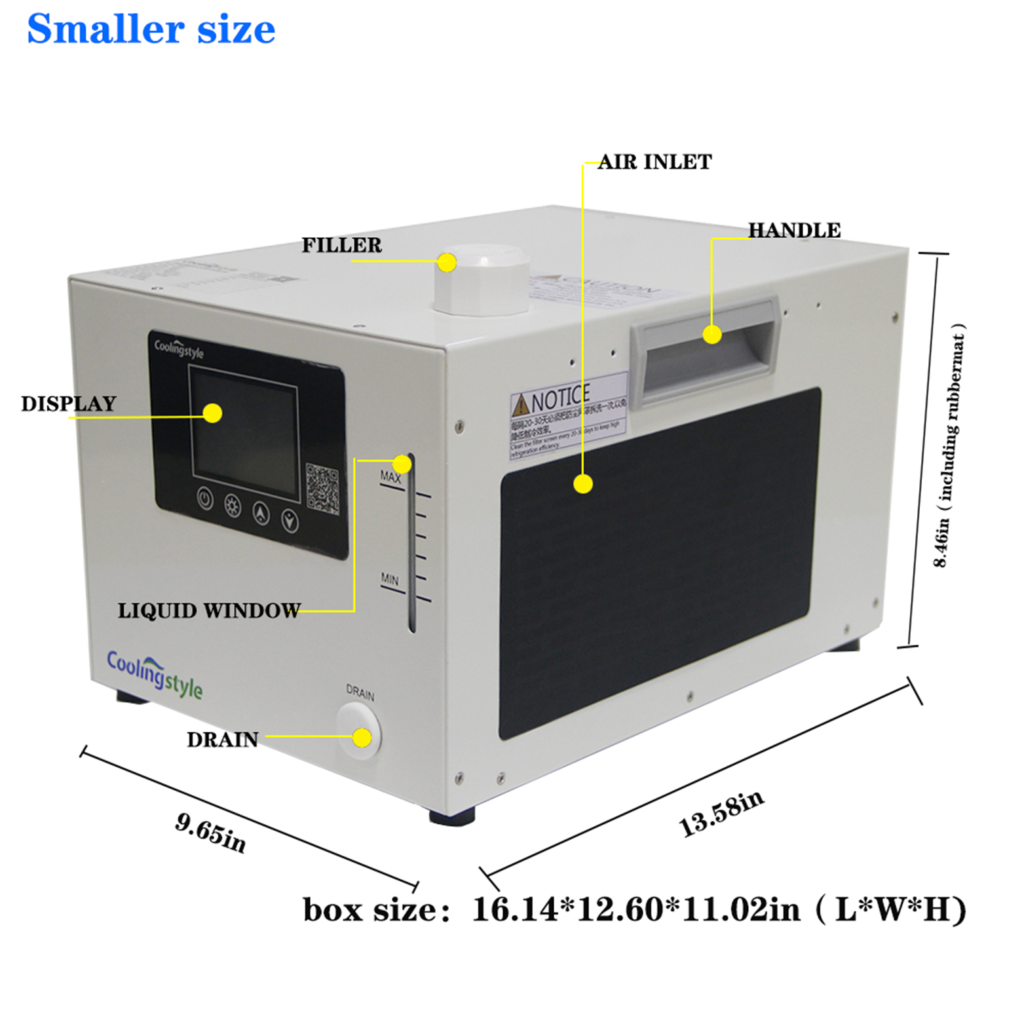

Micro Chiller

420W-580W Cooling Capacity Compact and efficient, ideal for small-scale laser systems requiring precise temperature control.

4U Rack Mount Chiller

500W-600W Cooling Capacity Designed for rack-mounted setups, providing consistent cooling for mid-range laser applications.

5U Rack Mount Chiller

1200W Cooling Capacity Offers powerful cooling in a rack-mount format, suitable for higher-demand laser systems.

1600W Chiller

1600W Cooling Capacity Optimized for medium-power lasers, delivering reliable temperature regulation for enhanced performance.

2700W Chiller

2700W Cooling Capacity Built for high-power laser applications, ensuring stable operation even under heavy workloads.

3D Printer Laser Chiller

Specifically designed for 3D printers, our cooling system ensures precise temperature control for optimal printing performance and stability.

Ensure Peak Performance with Coolingstyle

Choosing the right chiller is crucial for ensuring the stable operation of your laser equipment. We offer a range of chiller solutions tailored for various laser types and power ranges. Below are examples from our laser application selection database:

| Chiller Model | Nanosecond Laser | Picosecond Laser | ||||

|---|---|---|---|---|---|---|

| UV NS Laser | Green NS Laser | Red NS Laser | Purple PS Laser | Green PS Laser | Red PS Laser | |

| CS-ARC-Q420A110 | 0-10W | 0-20W | 0-200W | 0-5W | 0-10W | 0-30W |

| CS-ARC-Q4U2A110 | 0-10W | 0-20W | 0-200W | 0-5W | 0-10W | 0-30W |

| CS-ARC-Q580A110 | 10-20W | 20-30W | 200-300W | 5-10W | 0-20W | 0-45W |

| CS-ARC-Q4U2A111 | 10-20W | 20-30W | 200-300W | 5-10W | 0-20W | 0-45W |

| CS-ARC-Q5U3A111 | 10-30W | 30-60W | 300-500W | 10-15W | 0-45W | 0-70W |

| CS-ARC-M160A410 | 10-30W | 20-50W | 300-500W | 10-15W | 0-45W | 0-70W |

| CS-ARC-M270A410 | 30-50W | 30-60W | 500-1000W | 30-50W | 30-60W | 0-200W |

Technical advantages

Achieve precise temperature regulation with control accuracy up to ±0.01℃, ensuring optimal performance and longevity of your laser systems.

Reliable Performance in Extreme Conditions

Built to perform in demanding environments, our chillers ensure reliable operation even under extreme temperature and workload conditions.

Why Choose Coolingstyle Industrial Chiller

- Achieve Precision with ±0.1℃ Accuracy: You can count on exact temperature control, ensuring your equipment operates at peak efficiency.

- Over 100 Customizable Solutions: Whether you need cooling for small or large-scale applications, we’ve got you covered with more than 100 tailored options.

- Leverage Our 30+ R&D Experts: Your projects benefit from our team’s extensive experience in electronics, structural design, and software development.

- Save Up to 20% on Energy Costs: With our advanced frequency conversion technology, your operations become more cost-effective.

- Built on 100+ Patents: You gain from proven technology that delivers reliability and innovation in every unit.

- 1-Stop Solution from Concept to Production: You can streamline your project with our comprehensive design-to-production service, all under one roof.

- Trusted by Clients in 40+ Countries: You can rely on our global support network to keep your operations running smoothly.

FAQ's About Industrial Chillers

Coolingstyle provides a range of industrial chillers, including micro chillers, rack-mount chillers, and high-capacity chillers, designed to meet the cooling needs of various laser systems and industrial applications.

Our chillers are designed with high-precision temperature control, achieving accuracy up to ±0.01℃, ensuring consistent performance for your equipment.

Yes, Coolingstyle chillers are compatible with various laser types, including nanosecond UV, IR, and picosecond lasers, and can be customized to meet specific cooling requirements.

Key advantages include precise temperature control, energy efficiency through intelligent frequency conversion, compact design, and reliable operation in extreme conditions.

Yes, our chillers are designed for easy integration into existing industrial systems, offering flexible installation options to suit different setups.

Coolingstyle chillers are built for durability and require minimal maintenance. Regular checks and cleaning of filters and heat exchangers are recommended to ensure optimal performance.

Absolutely. Our chillers utilize intelligent frequency conversion technology, which adjusts the cooling output to match the system’s needs, reducing energy consumption and operational costs.

Coolingstyle chillers come with a 12-month warranty. After the warranty period, customers can purchase replacement parts for continued maintenance and operation.

You can use our laser application selection guide or consult with our technical support team to find the chiller model that best fits your specific requirements.

Your Trusted Partner in Precision Cooling Solutions

Looking for reliable, high-performance cooling systems tailored to your industry needs? Coolingstyle specializes in cutting-edge temperature control solutions. Our range of industrial chillers and portable cooling systems is designed to meet the specific requirements of diverse applications, ensuring precise, energy-efficient, and compact solutions.

Comprehensive One-Stop Design and Production

At Coolingstyle, we offer a full-spectrum, one-stop design service that takes your project from initial concept drawings all the way to mass production. Our complete in-house R&D team includes experts in electronics, structural engineering, hardware, and software development, ensuring seamless integration and high-quality results. With extensive experience across various industries, our team excels in transforming complex ideas into innovative, reliable products. Our multidisciplinary approach allows us to optimize every aspect of the design and manufacturing process, giving you a competitive edge with tailored solutions that are ready for market.

Join Us at the 2025 Munich Laser World of Photonics!

We’re excited to announce that Coolingstyle will be exhibiting at the 2025 Munich Laser World of Photonics, the leading trade fair for photonics technologies. We invite you to visit our booth, explore our latest innovations in industrial chillers, and discuss how we can support your cooling needs.

How to Choose Your Suitable Water Chiller?

Table of Contents

Understand Your Laser System’s Cooling Requirements

The first step in choosing a water chiller is understanding the specific cooling needs of your laser system. Different lasers generate varying amounts of heat, depending on their power output and application. For instance:

- Low to Medium Power Lasers (up to 20W): These are typically used in applications like laser engraving and marking. For such lasers, a compact micro chiller with a cooling capacity of around 420W to 580W would suffice. Precision temperature control with an accuracy of ±0.1°C is crucial to ensure consistent laser output.

- High Power Lasers (20W to 100W): Used in cutting and welding applications, these lasers require more robust cooling solutions. Rack-mounted chillers like the 4U or 5U series offer higher cooling capacities, ranging from 600W to 1200W, and are designed to handle the increased heat load effectively.

- Ultra-High Power Lasers (above 100W): These are typically used in industrial applications, including metal cutting and military use. Cooling systems for these lasers, such as the CS-2700 series with a cooling capacity of up to 2700W, are designed to handle intense heat and require precise temperature control to maintain stability.

Evaluate Chiller Features and Specifications

When comparing water chillers, focus on the features and specifications that will directly impact your laser’s performance and the chiller’s efficiency:

- Cooling Capacity: Ensure the chiller’s cooling capacity matches or exceeds the heat load generated by your laser system. Overloading a chiller beyond its rated capacity can lead to overheating and potential damage.

- Temperature Control Accuracy: Precision is key, especially for applications requiring consistent laser performance. Look for chillers that offer temperature control accuracy of ±0.1°C or better. This ensures that the laser operates within its optimal temperature range, reducing thermal stress and extending its lifespan.

- Alarm Systems: Safety features such as flow rate alarms, high/low temperature alarms, and overheat protection are vital for preventing damage to both the chiller and the laser system.

- Size and Portability: Depending on your workspace and the setup of your laser equipment, the size and portability of the chiller may be an important consideration. Compact and portable chillers are ideal for smaller operations or when flexibility in positioning is required.

Consider the Power Supply Compatibility

Ensure that the chiller is compatible with your facility’s power supply. Some chillers offer flexible power options, including AC220V (standard), AC110V, or DC24V, which can be particularly useful if you have varying power sources or if you’re operating in different regions with different voltage standards.

Assess the Environment and Application Needs

The environment where your laser system and chiller will be operating plays a significant role in your choice. For example:

- Industrial Settings: If the chiller will be used in a harsh industrial environment, durability and reliability are paramount. Look for robust construction, corrosion-resistant materials, and sealed components to protect against dust and moisture.

- Precision Applications: For applications like medical devices or scientific research, where precision is crucial, select a chiller with high-precision temperature control and minimal vibration to avoid interference with sensitive operations.

Check for Customization Options

Depending on your specific needs, you may require a customized cooling solution. Some manufacturers, like Coolingstyle, offer highly customizable options to cater to unique requirements, such as specialized temperature ranges, cooling capacities, or integration with existing equipment.

Review Manufacturer Support and Warranty

Finally, consider the level of support and warranty offered by the manufacturer. A reliable manufacturer will provide comprehensive support, including installation guidance, maintenance services, and readily available spare parts. Additionally, a robust warranty is a good indicator of the manufacturer’s confidence in their product’s quality and durability.

Conclusion

Choosing the right water chiller for your laser systems is a critical decision that can significantly impact your operations. By understanding your laser’s cooling needs, evaluating chiller specifications, and considering the operational environment, you can select a chiller that enhances performance, ensures reliability, and extends the lifespan of your laser equipment. Remember, a well-chosen chiller not only protects your investment but also optimizes your productivity and quality of output.

Ask for a quote

Interested to communicate for further details? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.