Precision temperature control is vital across various industries, from medical devices to industrial systems. DC frequency conversion control1 is the game changer in achieving this accuracy and efficiency.

DC frequency conversion control1 improves energy efficiency2 and precision in temperature management3 by adjusting the compressor speed based on cooling needs, ensuring stable and precise temperature regulation.

In this article, we will explore the significance of DC frequency conversion control1 in modern cooling systems, its operating mechanism, and how it benefits different applications, including the advanced systems developed by Coolingstyle.

Definition and Importance of DC Frequency Conversion Control in Cooling Systems

Understanding the role of DC frequency conversion control1 in cooling systems is crucial for industries requiring precise temperature management.

DC frequency conversion control1 refers to the technology that adjusts compressor speed4 in real-time, offering more precise and efficient cooling, which is vital for sensitive industrial and medical equipment.

DC frequency conversion control1 utilizes advanced inverter technology to regulate the speed of the compressor motor, adapting to the varying cooling demands. This results in significant energy savings5 as the system operates only at the necessary capacity, avoiding energy waste seen in traditional on/off systems.

How DC Frequency Conversion Works

The core of this technology lies in its ability to adjust the compressor’s motor speed. Unlike traditional systems that operate at a constant speed, DC frequency control systems6 use variable-speed drives (VSDs)7 to modulate the speed of the compressor. This fine-tuning allows for more accurate temperature regulation and reduces wear and tear on system components.

This precise control mechanism provides several advantages:

-

Energy Efficiency2: The system consumes only the energy required to meet the cooling demand, reducing overall power consumption.

-

Enhanced Longevity8: By avoiding constant on/off cycling, the compressor experiences less strain, extending its lifespan.

-

Noise Reduction9: Variable-speed compressors operate more quietly compared to fixed-speed models, as they are not running at full power all the time.

In practical terms, Coolingstyle’s products leverage DC frequency conversion to ensure a higher level of accuracy and efficiency, particularly in sensitive environments like laser cooling and medical devices.

Benefits in Precision Temperature Management

One of the most important aspects of DC frequency conversion10 control is its ability to maintain a stable, precise temperature across varying conditions. For example, in medical therapy systems where temperature must be controlled within a narrow range, DC frequency conversion10 allows for consistent cooling and minimizes fluctuations that could lead to errors or safety concerns.

Furthermore, as industries continue to shift towards more sustainable solutions, the energy efficiency2 of DC frequency control becomes increasingly valuable. Coolingstyle’s commitment to reducing energy consumption aligns with global environmental goals, making it an ideal choice for sectors where energy savings are a priority.

Mechanism of DC Frequency Conversion Control

How does DC frequency conversion control1 work to achieve these remarkable benefits in temperature regulation?

DC frequency conversion control1 works by dynamically adjusting the compressor speed based on cooling demand. This real-time adaptation ensures optimal temperature control with minimal energy consumption.

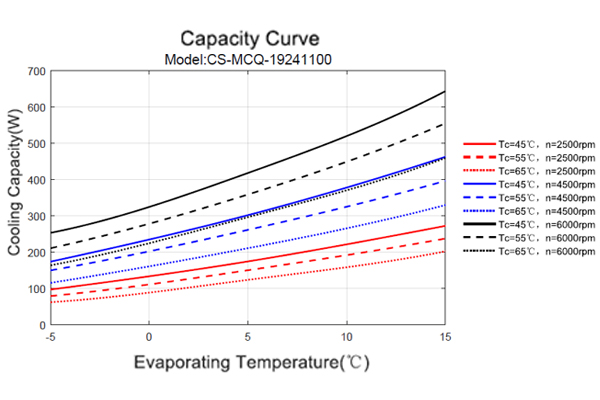

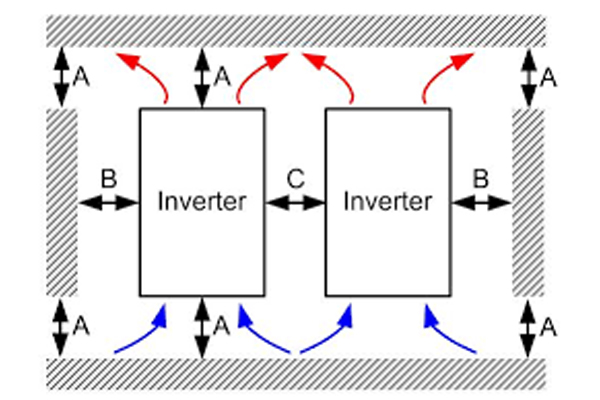

The mechanism of DC frequency conversion is powered by an inverter that adjusts the power supply to the compressor. When cooling demand is low, the inverter reduces the speed of the compressor, and when cooling demand is high, the speed increases. This continuous modulation allows the system to respond efficiently to changing conditions.

This system’s key components include:

-

Inverter Technology11: The inverter adjusts the motor speed by converting incoming AC power to DC, then back to AC at the desired frequency.

-

Sensors and Controllers: Temperature sensors constantly monitor the environment, providing real-time data to the controller, which adjusts the compressor speed to maintain the target temperature.

-

Cooling Algorithms12: Sophisticated algorithms calculate the optimal compressor speed needed to meet cooling demands, based on factors such as ambient temperature, load changes, and system efficiency.

Coolingstyle has integrated these components into our systems, ensuring that even the most demanding applications, such as laser cooling machines or high-precision industrial devices, achieve high levels of performance and reliability.

Advantages of DC Frequency Conversion Control

What makes DC frequency conversion control stand out in temperature management? Let’s explore the major advantages.

The main advantages of DC frequency conversion control include energy efficiency2, longer equipment life13, quieter operation, and improved temperature stability, making it ideal for precise and demanding cooling applications.

DC frequency conversion control’s benefits are not just theoretical but are realized in various real-world applications. For industries where energy efficiency2 and precision are paramount, such as medical and industrial cooling, the ability to adjust compressor speed for optimal cooling is a significant advantage.

-

Energy Efficiency: Traditional cooling systems operate at full power, regardless of the actual cooling need. DC frequency conversion10 systems, however, adjust the compressor speed in real time, leading to a significant reduction in energy consumption14.

-

Longer Equipment Life: Because the compressor avoids the stress of constant on/off cycling, its lifespan is extended. This is particularly important for expensive systems in industries like medical therapy and laser technology, where equipment downtime can be costly.

-

Quieter Operation: Fixed-speed compressors can be noisy, especially when they constantly turn on and off. DC frequency conversion10 systems run more smoothly and quietly, making them ideal for environments like laboratories or hospitals, where noise control is a priority.

-

Precise Temperature Control: By continuously adjusting the compressor’s speed, DC frequency conversion10 ensures that the temperature remains within a very narrow range, crucial for applications like semiconductor manufacturing, medical therapies, and high-precision industrial machinery.

These benefits make DC frequency conversion10 control a game-changer for industries requiring reliable, energy-efficient, and precise temperature management.

Applications of DC Frequency Conversion Control

Where can DC frequency conversion control1 technology be applied, and how does it enhance the performance of cooling systems in these industries?

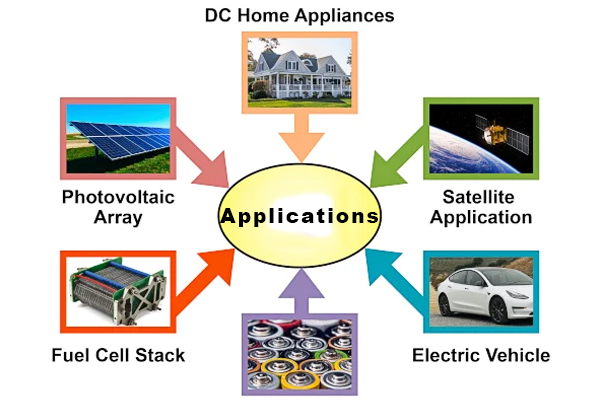

DC frequency conversion control1 is used in a wide range of industries, including medical, laser, and industrial sectors, where precision temperature control15 is critical for system performance.

DC frequency conversion control1 is particularly valuable in industries where temperature fluctuations16 can lead to performance issues, equipment failure, or compromised safety. Let’s look at a few examples:

Medical Applications

In medical devices such as cooling systems for medical therapy, maintaining a precise temperature is essential for patient safety and treatment efficacy. Coolingstyle’s medical cooling systems17, utilizing DC frequency conversion control, ensure that temperature variations are minimized, providing a stable environment for treatments like cryotherapy18 and laser therapies19.

Laser Cooling

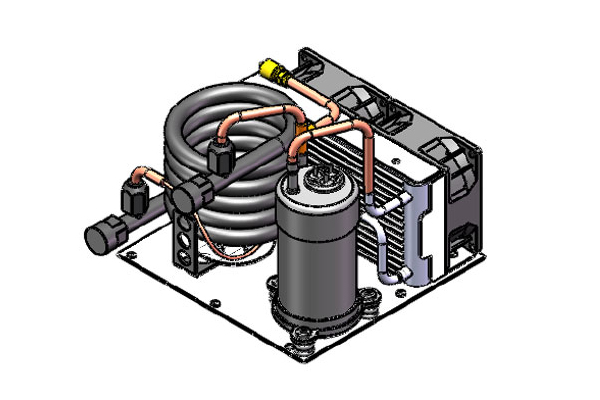

For laser equipment, such as laser cutting and engraving systems, cooling is crucial to prevent overheating and ensure consistent output. The Q580 series laser chillers20 by Coolingstyle incorporate DC frequency conversion control1, allowing the system to adjust its cooling output to match the laser’s heat load. This ensures stable operation, reduces energy consumption14, and extends the lifespan of the laser equipment.

Industrial Applications

In industrial environments, temperature control is often required for machinery, electronics, and other sensitive equipment. The M160 and M270 series industrial chillers21 are examples of Coolingstyle’s solutions that integrate DC frequency conversion control1 to deliver energy-efficient and reliable cooling, ensuring that industrial operations run smoothly without interruptions due to overheating.

How Coolingstyle Achieves High Precision of DC Frequency Conversion Control in Cooling Systems

What sets Coolingstyle apart in implementing DC frequency conversion10 control in its products?

Coolingstyle’s products are built with high-precision components, including micro compressors22 and advanced cooling algorithms23, which enable real-time, precise adjustments to cooling systems based on DC frequency conversion10 technology.

At Coolingstyle, achieving high precision in temperature control starts with the foundational technology of DC frequency conversion10. Our proprietary micro compressors22, combined with advanced inverter technology, form the backbone of our cooling systems.

By incorporating precision sensors24 and sophisticated control algorithms, Coolingstyle systems can adjust the compressor speed to within a fraction of a degree, ensuring that the desired temperature is maintained even under fluctuating conditions. This is particularly critical in applications like medical therapy systems or laser cooling, where even small temperature deviations can lead to significant performance issues.

Furthermore, our commitment to R&D ensures that each product undergoes rigorous testing and fine-tuning to meet the exacting standards required by industries demanding precision. Through continuous innovation, Coolingstyle maintains its leadership in the field of high-precision temperature control25, providing solutions that are both reliable and energy-efficient.

Conclusion

DC frequency conversion control1 is a transformative technology in the field of temperature management, offering energy efficiency, longer equipment life, and superior temperature precision, making it an ideal solution for modern cooling systems across various industries.

-

Explore this link to understand how DC frequency conversion control revolutionizes temperature management in various industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the importance of energy efficiency in temperature control systems and its benefits for sustainability. ↩ ↩ ↩ ↩ ↩

-

Discover best practices for temperature management that can enhance performance and reliability in industrial applications. ↩

-

Learn how adjusting compressor speed can lead to significant energy savings and better temperature management in cooling systems. ↩

-

Discover the importance of energy savings in cooling systems and how it impacts operational costs and environmental sustainability. ↩

-

Explore this link to understand the mechanics and benefits of DC frequency control systems in various applications. ↩

-

Learn about VSDs and how they enhance energy efficiency and performance in cooling systems. ↩

-

Learn how enhanced longevity can lead to better performance and lower maintenance costs for compressors. ↩

-

Discover how noise reduction can improve comfort and productivity in various settings by exploring this resource. ↩

-

Explore this link to understand how DC frequency conversion enhances temperature management and energy efficiency in various applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about inverter technology’s role in HVAC systems and its impact on energy efficiency and performance. ↩

-

Discover how cooling algorithms enhance temperature control and efficiency in various applications. ↩

-

Learn how DC frequency conversion control can extend the lifespan of critical equipment, reducing maintenance costs and downtime. ↩

-

Learn about the significant energy savings achieved through advanced cooling technologies like DC frequency conversion. ↩ ↩

-

Understanding the significance of precision temperature control can help improve system performance and prevent failures. ↩

-

Learn about the impact of temperature fluctuations on equipment and safety, and how to mitigate these risks. ↩

-

Explore how medical cooling systems enhance patient safety and treatment efficacy in various therapies. ↩

-

Learn about cryotherapy’s benefits and applications in medical treatments, enhancing your understanding of this therapy. ↩

-

Discover the various applications of laser therapies in medicine and how they improve treatment outcomes. ↩

-

Explore how laser chillers enhance performance and longevity in laser systems, ensuring optimal operation and energy efficiency. ↩

-

Discovering the best industrial chillers can help you choose the right equipment for maintaining optimal temperature in your operations. ↩

-

Learn about micro compressors and their role in enhancing cooling efficiency and precision in various applications. ↩ ↩

-

Discover how advanced cooling algorithms optimize temperature control, ensuring reliability and efficiency in cooling solutions. ↩

-

Explore how precision sensors enhance temperature control, ensuring reliability and efficiency in critical applications. ↩

-

Learn about high-precision temperature control and its vital role in industries like medical therapy and laser cooling. ↩