When using a 3D laser engraving machine1, especially one with a UV laser source2, cooling is a crucial factor in maintaining efficiency and precision. Overheating can affect engraving accuracy, reduce laser lifespan, and even damage delicate optical components. This is where a high-precision chiller3 like the Coolingstyle CS-ARC-Q580A112 comes into play. Let’s explore why this cooling system is essential for your 3D laser engraving setup.

Why Do 3D Laser Engraving Machines Need a Chiller?

1. UV Laser Stability and Performance

UV lasers operate at 355nm4, a short-wavelength laser that requires stable temperature control to maintain performance. If the temperature fluctuates, you might face:

-

Power instability5, affecting engraving depth and precision.

-

Distorted laser beams, leading to poor engraving quality.

-

Shortened laser lifespan, increasing maintenance costs.

A chiller helps maintain the UV laser within an optimal range (18-22°C)6, ensuring stable operation.

2. Preventing Overheating During Long Working Hours

3D engraving machines require continuous, high-precision laser pulses, generating heat. This is particularly important for high-power UV lasers (10W and above)7, which can overheat quickly. A chiller prevents excessive heat buildup8, ensuring uninterrupted production and high-quality engraving.

3. Protecting Optical Components

-

Lenses, galvanometers, and beam expanders are temperature-sensitive.

-

Overheating can lead to thermal expansion, shifting the focal point and reducing engraving accuracy.

-

A stable cooling system prevents thermal drift9, keeping the engraving process precise and repeatable.

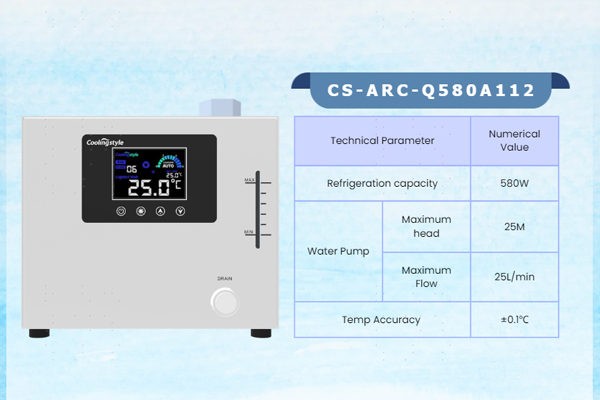

Why Choose the Coolingstyle CS-ARC-Q580A112 Chiller?

If your 3D laser engraving machine1 uses a UV laser, the Coolingstyle CS-ARC-Q580A112 is an ideal chiller solution. Here’s why:

✅ High-Precision Temperature Control (±0.1℃)10

-

Ensures stable laser operation with minimal fluctuations.

-

Prevents power instability and beam distortion.

✅ Compact Design – Ideal for Small & Industrial Applications

- Space-saving and highly integrated, making it perfect for desktop and industrial 3D engraving machines.

✅ 580W Cooling Power – Suitable for UV Lasers (3W-15W)11

- Prevents overheating during long engraving sessions.

✅ Intelligent Temperature Control System

-

Automatically adjusts water temperature based on ambient conditions.

-

Keeps UV laser at the optimal 18-22°C working range.

✅ Low Noise, Energy-Efficient Design

-

Suitable for labs, production lines, and engraving workshops.

-

- –

Recommended Cooling Power Based on UV Laser Wattage

| UV Laser Power12 | Recommended Chiller Cooling Power13 | Recommended Model |

|---|---|---|

| 3W – 10W | 500W – 1000W | CS-ARC-Q580A112 ✅ |

| 10W – 20W | 1000W – 2000W | CS-ARC-Q580A112 (Customizable) |

| 20W+ | 2000W+ | Custom Industrial Chiller14 |

Conclusion: The CS-ARC-Q580A11215 is the Ideal Chiller for 3D Engraving Machines

⭐ Precision Cooling (±0.1°C) to Ensure Stable UV Laser Performance\

⭐ Compact and Space-Saving, Perfect for Desktop 3D Engraving Machines\

⭐ Low Noise and Energy-Efficient for Long-Term Industrial Use\

⭐ Smart Temperature Control to Prevent Overcooling or Overheating

If your 3D laser engraving machine1 has a 3W-15W UV laser, the CS-ARC-Q580A11215 is the perfect cooling solution. For higher-power lasers, Coolingstyle offers customizable options16. Need more details or a comparison? Let us know!

-

Discover the advantages of 3D laser engraving machines and how they can enhance your projects. ↩ ↩ ↩

-

Learn about the technology behind UV laser sources and their impact on engraving quality. ↩

-

Understand the role of high-precision chillers in maintaining optimal performance for laser machines. ↩

-

Understanding the importance of 355nm can enhance your knowledge of laser engraving technology and its applications. ↩

-

Learning about power instability can help you troubleshoot and improve your laser engraving processes effectively. ↩

-

Exploring this topic will provide insights into the critical role of chillers in laser performance and longevity. ↩

-

Understanding the management of high-power UV lasers is crucial for maintaining performance and preventing damage. Explore this resource for expert insights. ↩

-

Learn how chillers work to maintain optimal temperatures in laser engraving, ensuring efficiency and quality in production. ↩

-

Discover why a stable cooling system is vital for precision in laser engraving, preventing costly errors and enhancing quality. ↩

-

Learn how high-precision temperature control can enhance the performance and longevity of laser engraving machines. ↩

-

Discover why adequate cooling power is crucial for maintaining optimal performance in UV laser engraving applications. ↩

-

Discover how UV laser power impacts cooling needs to ensure efficient operation and prevent overheating. This resource will enhance your knowledge. ↩

-

Understanding the recommended chiller cooling power is crucial for optimal UV laser performance and longevity. Explore this link for detailed insights. ↩

-

Learn about the advantages of custom industrial chillers for UV lasers, ensuring maximum efficiency and reliability in your operations. ↩

-

Learn more about the CS-ARC-Q580A112 chiller’s features and benefits to see how it can enhance your 3D engraving machine’s performance. ↩ ↩

-

Check out this resource to find out about Coolingstyle’s customizable cooling options, perfect for various laser engraving needs. ↩