What is a High-Power Solid-State Laser1?

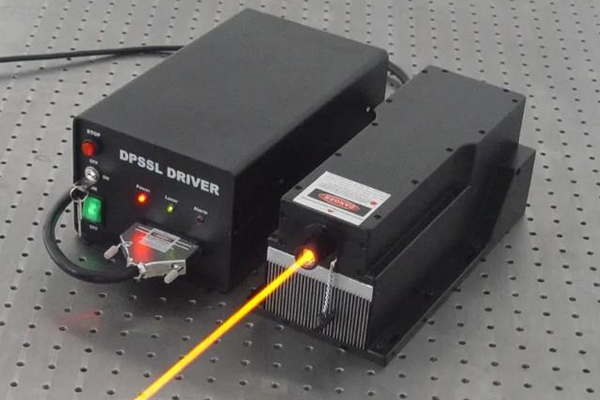

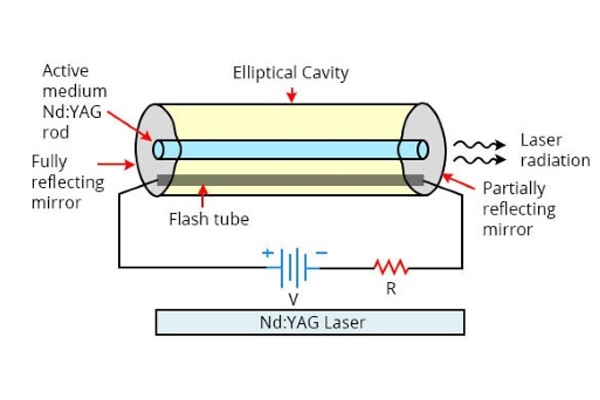

A High-Power Solid-State Laser1 (HPSSL) is a laser that uses a solid gain medium (such as ion-doped crystals or glass) as its working material and is capable of generating high-power laser output. Common gain media include Nd:YAG2 (neodymium-doped yttrium aluminum garnet), Yb:YAG3 (ytterbium-doped yttrium aluminum garnet), and neodymium-doped glass. These lasers are widely used in industrial manufacturing, precision machining, medical applications, scientific research, and military fields due to their high power output, strong stability, and high energy conversion efficiency.

Operating Principle of High-Power Solid-State Lasers

High-power solid-state lasers are pumped by external light sources (usually diode lasers or flash lamps) to excite the gain medium4, causing the activated ions within it to transition to a higher energy level. When these activated ions return to a lower energy level, they release photons, forming stimulated emission5, which is ultimately amplified through a resonant cavity to produce high-power laser output.

Application Fields

· Industrial Manufacturing6: Laser cutting, welding, drilling, marking, and other high-precision machining.

· Military & Defense: Laser weapons, target illumination, electro-optical countermeasures.

· Scientific Research7: Laser fusion (such as NIF, Shenguang series), ultrafast optics, particle acceleration.

· Medical Applications8: Ophthalmic surgery (such as LASIK), tumor treatment, biomedical imaging.

The Need for High-Precision Temperature Control in Chillers for High-Power Solid-State Lasers

During the operation of high-power solid-state lasers, the stability of the cooling system directly determines the performance and lifespan of the laser. The temperature accuracy of the chiller is particularly critical, typically requiring control within ±0.1℃ or even more precise ranges. As a leader in precision temperature control, Coolingstyle provides high-precision laser chillers9 to meet the stringent cooling requirements of laser systems.

1. Managing Thermal Effects

High-power solid-state lasers generate a large amount of heat, primarily concentrated within the gain medium (such as Nd:YAG, Yb:YAG, or neodymium-doped glass). If this heat is not effectively removed in time, the temperature of the gain medium will rise, leading to thermal lensing effects10.

The Q580 series laser chiller11 from Coolingstyle utilizes micro direct current (DC) variable-frequency compressor technology and variable-frequency control algorithms12 to precisely match the heat load of the laser, ensuring that temperature fluctuations remain within ±0.1℃. This effectively suppresses thermal lensing effects10, improving laser beam quality and machining precision.

2. Wavelength Stability

The output wavelength of solid-state lasers is highly sensitive to temperature. The refractive index or lattice parameters of the gain medium undergo slight variations with temperature changes, leading to wavelength drift13. In high-precision applications such as laser machining, spectroscopy, or medical fields, even a 0.1℃ temperature variation can cause significant effects.

Coolingstyle chillers feature a high-definition LCD intelligent display14, allowing real-time temperature monitoring15 to ensure wavelength stability and prevent wavelength drift13 from affecting machining quality.

3. Enhancing Power Efficiency and Extending Equipment Lifespan

Temperature fluctuations not only affect laser beam quality but also reduce the absorption efficiency of pump light, thereby impacting overall power output. Coolingstyle chillers utilize environmentally friendly R134a refrigerant16 combined with PID intelligent control algorithms17 to achieve efficient temperature control and optimize energy conversion efficiency.

Furthermore, precise temperature control reduces thermal stress on the gain medium18, minimizing the risk of microcracks, thereby significantly extending the lifespan of the laser.

4. Ensuring System Stability for High-End Applications

High-power solid-state lasers are widely used in industrial manufacturing, scientific research, and military applications, where equipment stability and reliability are critical. Excessive temperature fluctuations in the chiller can lead to:

· Uneven cooling, causing localized overheating or condensation, which affects optical component performance.

· Unstable laser power, impacting precision machining quality such as cutting and welding.

· Increased maintenance costs, raising failure risks and affecting production efficiency.

Coolingstyle’s Q420 and Q580 series laser chillers19 are equipped with a multi-alarm system20 (high-temperature alarm, low-temperature alarm, and flow alarm) to ensure safe and stable operation, meeting the demands of high-end laser applications.

Conclusion

The temperature accuracy requirements for chillers used in high-power solid-state lasers are much stricter than those for general industrial equipment. This is primarily to control thermal lensing effects, minimize wavelength drift, improve power efficiency, and extend equipment lifespan. Coolingstyle’s high-precision laser chillers9, featuring micro DC variable-frequency compressors, high-precision temperature control technology, and intelligent control systems, are the ideal choice for cooling high-power laser systems.

For laser systems requiring high-precision cooling, choosing a chiller with a temperature control accuracy21 of ±0.1℃ or better can significantly improve thermal management22, ensuring stable operation even at maximum power. Therefore, in the laser industry, advanced cooling systems have become a crucial supporting technology for high-power solid-state lasers.

The Advantages of Coolingstyle High-Precision Chillers

Coolingstyle specializes in high-precision temperature control technology, and its chillers offer the following core advantages:

1. Ultra-high temperature control accuracy23: Temperature fluctuations can be controlled within ±0.1℃, with some customized modes achieving ±0.01℃, ensuring that lasers remain in optimal working conditions.

2. Intelligent temperature control algorithms24: Combining PID control and variable-frequency technology, the system automatically adjusts cooling power, optimizing energy efficiency and enhancing operational stability.

3. Compact design and easy installation: The products have a compact structure and lightweight design25, making them suitable for various industrial and scientific research applications, especially in space-constrained environments.

4. Multiple safety protections26: Built-in high-temperature, low-temperature, and flow alarms ensure timely user notifications in case of abnormalities.

5. Environmentally friendly and energy-efficient27: Uses R134a refrigerant, compliant with international environmental standards, while optimizing energy consumption to reduce operational costs.

Coolingstyle chillers are widely used in laser processing, precision instrumentation, and laboratory equipment, providing high-precision temperature control28 to help customers achieve more efficient and stable production and research outcomes.

-

Explore this link to understand the diverse applications of HPSSLs in various industries, enhancing your knowledge of their significance. ↩ ↩

-

Discover the unique properties and applications of Nd:YAG lasers, which are crucial in many high-power laser systems. ↩

-

Learn about the benefits of Yb:YAG lasers, including their efficiency and performance in high-power applications. ↩

-

Understanding the gain medium is crucial for grasping how lasers work and their efficiency. ↩

-

Learn about stimulated emission to better understand the fundamental principles of laser technology. ↩

-

Explore how laser technology enhances precision and efficiency in industrial manufacturing processes. ↩

-

Learn about groundbreaking advancements in scientific research facilitated by laser technology. ↩

-

Discover the transformative impact of lasers in medical fields like surgery and imaging. ↩

-

Explore the advantages of high-precision laser chillers to enhance laser performance and longevity, crucial for high-power applications. ↩ ↩

-

Discover the causes of thermal lensing effects and effective strategies to mitigate them for better laser performance. ↩ ↩

-

Explore the Q580 series laser chiller to understand its advanced cooling technology and how it enhances laser performance. ↩

-

Learn about variable-frequency control algorithms and their role in optimizing cooling efficiency for high-power lasers. ↩

-

Understanding the causes of wavelength drift can help in selecting the right cooling solutions for laser applications. ↩ ↩

-

Explore how high-definition LCD displays enhance monitoring and control in laser systems, ensuring optimal performance and stability. ↩

-

Learn about the importance of temperature monitoring in maintaining precision and quality in laser machining processes. ↩

-

Explore the advantages of R134a refrigerant, including its environmental impact and efficiency in cooling systems. ↩

-

Learn how PID algorithms enhance control systems, leading to better energy efficiency and performance in various applications. ↩

-

Understand the effects of thermal stress on lasers and how managing it can prolong equipment lifespan and performance. ↩

-

Learn about the advanced features of Q420 and Q580 series laser chillers, designed for optimal performance in high-end laser applications. ↩

-

Discover how a multi-alarm system enhances equipment reliability and safety, crucial for high-end applications in manufacturing and research. ↩

-

Understanding the significance of temperature control accuracy can help you appreciate its role in improving laser system performance. ↩

-

Learn about effective thermal management strategies to maintain optimal performance in high-power laser applications. ↩

-

Explore how ultra-high temperature control accuracy can enhance your processes and ensure optimal performance in sensitive applications. ↩

-

Learn about the advantages of intelligent algorithms in optimizing energy efficiency and stability in cooling systems. ↩

-

Explore how a compact and lightweight design can enhance efficiency and adaptability in various industrial settings. ↩

-

Understanding the importance of safety protections can enhance your knowledge of cooling systems and their reliability. ↩

-

Exploring energy efficiency can help you discover ways to reduce costs and improve sustainability in your operations. ↩

-

Learning about high-precision temperature control can provide insights into improving production and research outcomes. ↩