Wide Temperature Range Control Solutions

Looking for a tailored cooling solution? At Coolingstyle, we specialize in custom temperature control systems designed to meet the unique needs of your industry. Whether you’re in the semiconductor, biopharmaceutical, or laboratory sector, our expert team will work with you to develop precise and reliable temperature regulation solutions.

Miniature Compressor

CSMC-Q0142100

Displacement: 1.4cc Power: 24V Cooling capacity: 100-400W

CSMC-Q0192100

Displacement: 1.9cc Power: 24V Cooling capacity: 300-500W

CSMC-Q0282100

Displacement: 2.8cc Power: 24V Cooling capacity: 500-600W

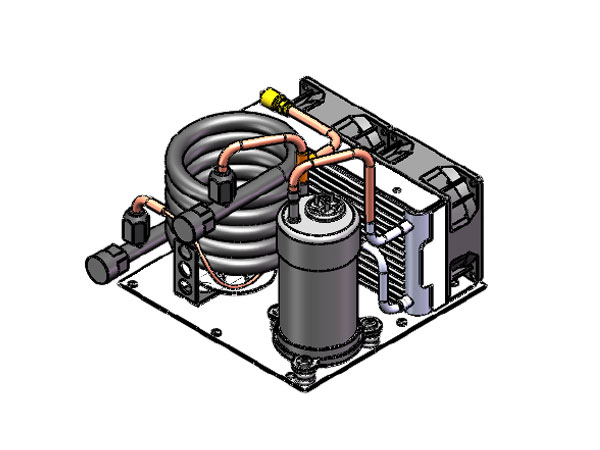

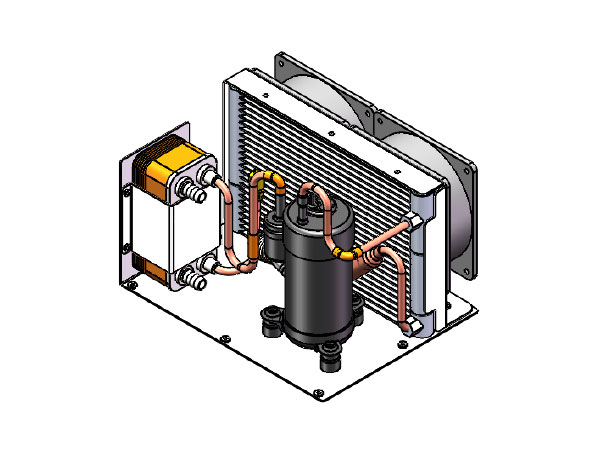

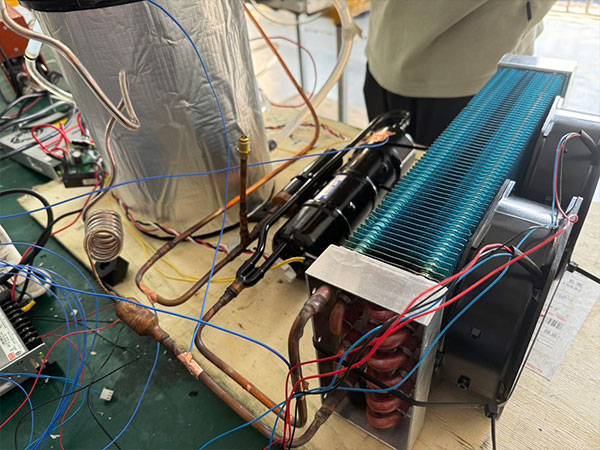

Custom Cooling Module for Inbuilt Cooling Solution

Are you looking to enhance the performance of your existing products with integrated cooling solutions? Our tailored cooling modules allow you to achieve effective temperature management, ensuring optimal reliability and efficiency within your designs.

CS-ARM-Q4202110

Compressor: 1.9cc, 24V DC

Refrigerant: R134a/R290

Evaporator: copper brazing/nickel brazing

Cooling capacity: 100-500W

Size: 246*190*146mm

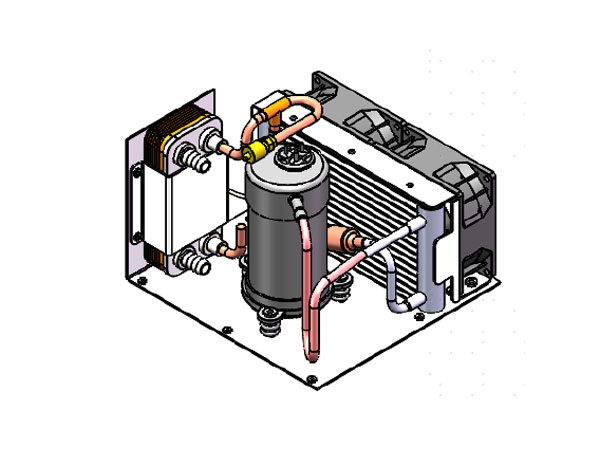

CS-ARM-Q5802110

Compressor: 2.8cc, 24V DC compressor Refrigerant: R134a/R290 Evaporator: copper brazing/nickel brazing Cooling capacity: 100-600W Size: 190*190*193mm

CS-ARM-Q1002110

Compressor: dual 1.9cc, 24V DC compressor Refrigerant: R134a/R290 Evaporator: copper brazing/nickel brazing Cooling capacity: 500-1000W Size: 356*254*160mm

CS-ARM-Q5802213

Compressor: 2.8cc, 24V DC compressor Refrigerant: R134a/R290 Evaporator: Coaxial tube evaporator Cooling capacity: 100-600W Size: 204*219*174mm

CS-ARM-Q5802111

Compressor: 2.8cc, 24/48V DC compressor Refrigerant: R134a/R290 Evaporator: copper brazing/nickel brazing Cooling capacity: 100-500W Size: 198*190*148mm

CS-ARM-Q6002210

Compressor: 3.8cc, 24/48V DC compressor Refrigerant: R134a/R290 Evaporator: copper brazing/nickel brazing Cooling capacity: 100-600W Size: 246*190*180mm

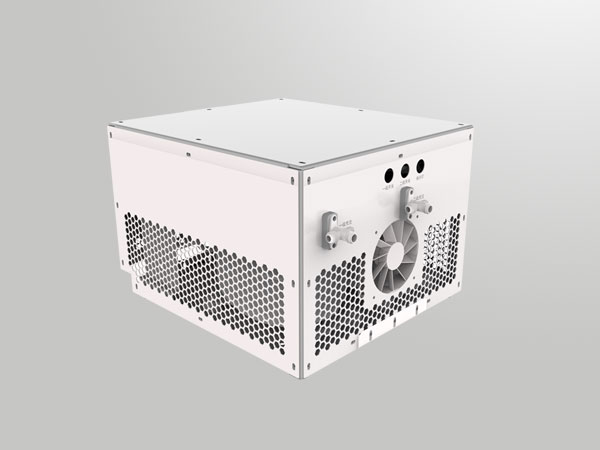

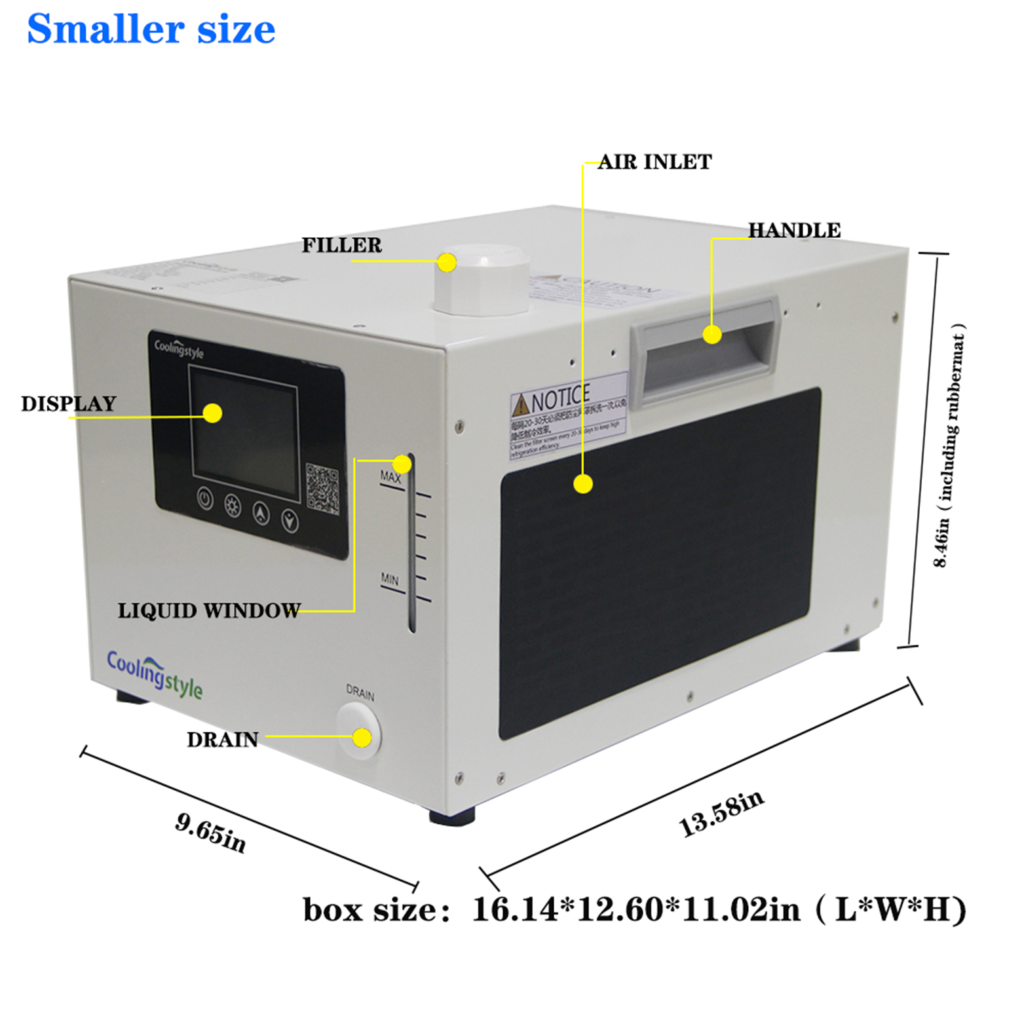

Custom Cooling Chiller Solution

Do you need a comprehensive cooling solution that covers all aspects of development? We provide complete services, from structural design to electronic control, offering a one-stop solution that meets your specific needs and simplifies the entire process.

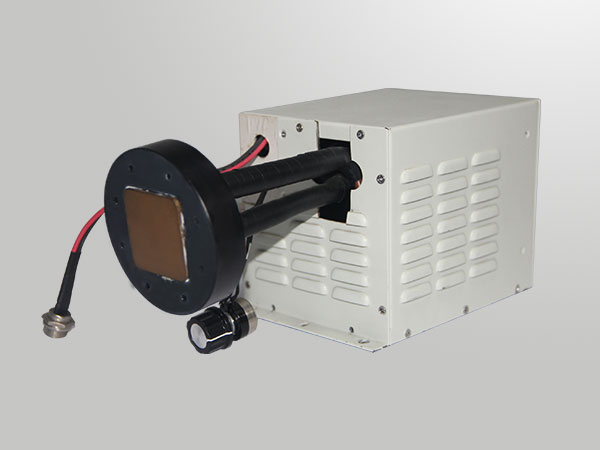

Electronic Semiconductor Testing Industry

Our chip cooling equipment is designed specifically for semiconductor testing, providing precise temperature control with cooling capabilities down to -18℃. This ensures accurate and reliable performance during chip testing, making it ideal for optimizing functionality and stability in advanced semiconductor applications.

Low-Temperature Cascade Chiller

Our Low-Temperature Cascade Chiller offers a wide temperature range from -55℃ to 150℃ with precision control of ±1.0℃. Designed for critical applications like industrial processes and semiconductor testing, it ensures reliable and energy-efficient cooling, enhancing performance and operational stability in extreme conditions.

Biomedical Cooling Solution

Our biomedical cooling system operates efficiently in environments ranging from -10℃ to 40℃, offering a cooling capacity of 300W at 25℃ ambient temperature. With precise temperature control accuracy of ±0.1℃ at a designated point, the system automatically maintains the desired set temperature. Powered by DC 24V with low power consumption of ≤300W, this solution is ideal for maintaining stable conditions in sensitive biomedical processes.

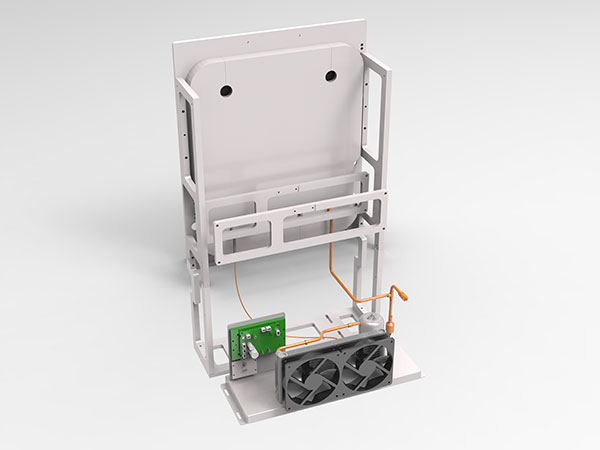

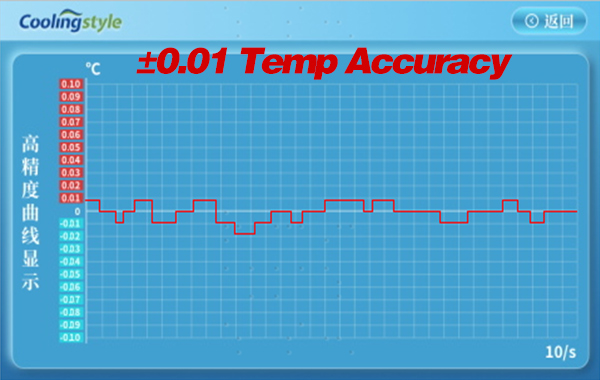

Precision Temperature Control System for Battery Testing

Our cooling system is specifically engineered for battery testing, where maintaining a constant 25℃ environment is critical for accurate assessments. It offers precise temperature control with an accuracy of ±0.1℃, making it perfect for managing heat sources with a thermal load of less than 1000W. This ensures stable, reliable testing conditions, improving the consistency and quality of battery performance evaluations.

Your Trusted Partner in Precision Cooling Solutions

Interested in learning more about our wide temperature range control solutions? Contact us today to discuss your specific needs and find out how our systems can benefit your operations.

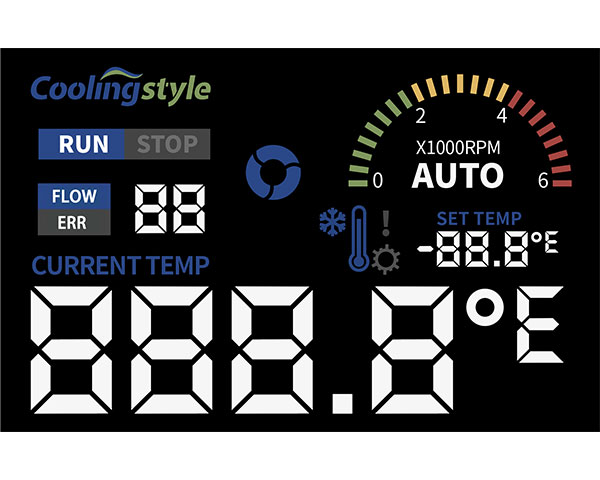

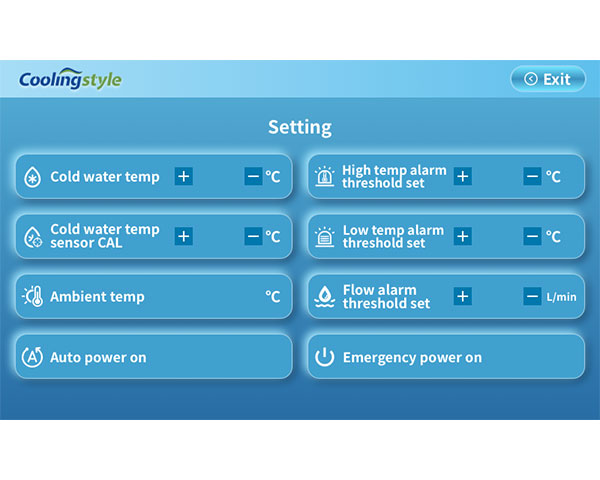

Advanced Software Solutions for Precision Cooling Control

At Coolingstyle, we offer tailored software development services to meet the unique needs of our clients. Whether it’s integrating precise temperature control, optimizing system efficiency, or customizing communication protocols, our team of experts is ready to develop and deliver software solutions that align perfectly with your specific requirements. With our extensive experience in control systems, we ensure that your cooling systems operate seamlessly and efficiently, providing the flexibility and performance your business demands.

Want to customize your products?

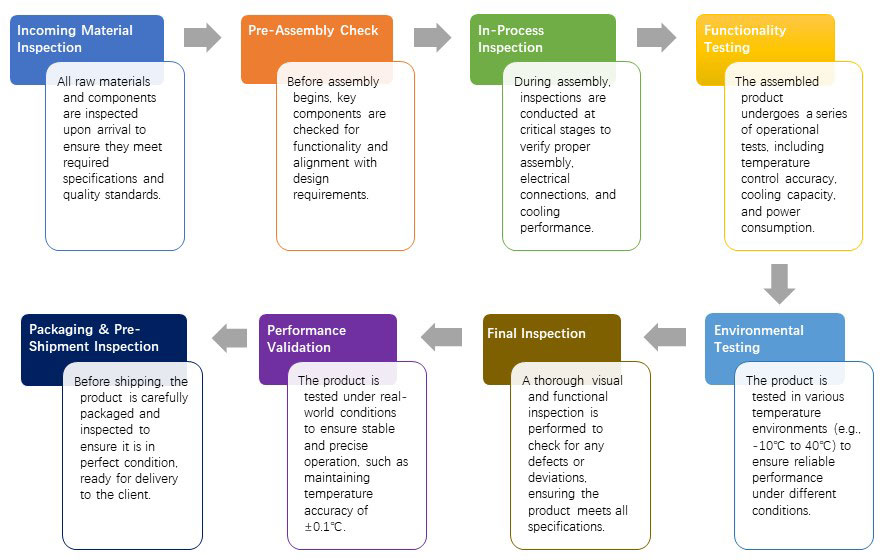

Our General Product Customization Process

We offer comprehensive temperature control solutions tailored for the consumer goods industry, integrating precision control technology with smart systems to meet your specific needs. Whether it’s for the storage and transportation of food and beverages or temperature management during cosmetics production, our solutions ensure optimal conditions to maintain product quality. In addition, we provide one-stop services, including electronic hardware and software development, structural design, cooling system engineering, and mass production, offering end-to-end support for businesses of all sizes.

Consultation & Requirements

We begin by engaging with the client to understand their specific needs, including performance goals, application environments, and any unique technical requirements. This helps us tailor the solution to fit their project’s exact demands.

Feasibility Study

After understanding the client's requirements, we conduct a feasibility analysis to determine the technical viability of the project. This ensures that our proposed solution aligns with the client's objectives and meets industry standards.

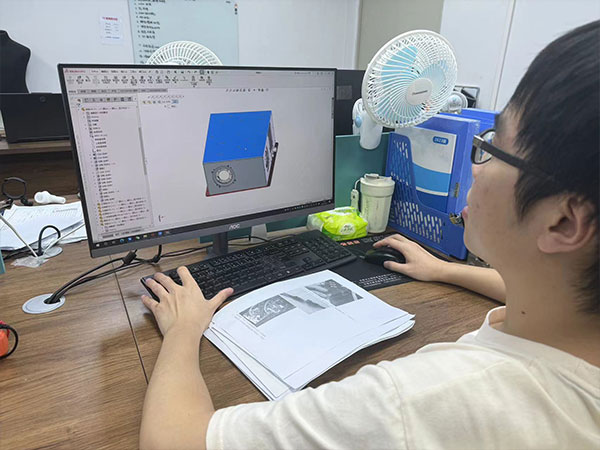

Concept Design

Based on the feasibility study, we create a detailed concept design that incorporates cooling technology, control systems, and structural elements. This stage provides a clear vision of how the final product will function and perform.

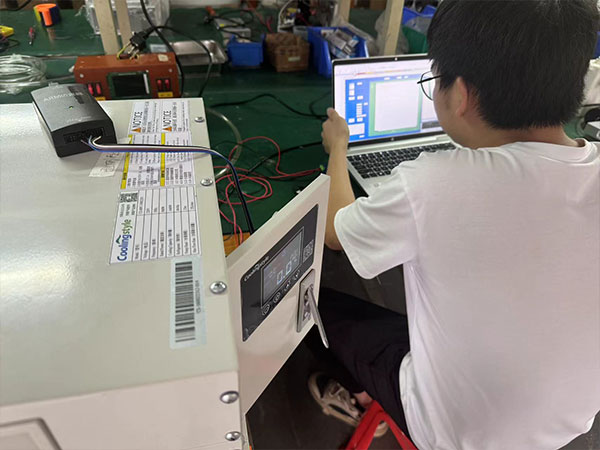

Prototype Development

Once the concept is approved, we move forward with developing a functional prototype. This includes designing, integrating, and assembling all components such as cooling units, electronics, and mechanical structures.

Testing & Validation

The prototype undergoes extensive testing to validate performance, reliability, and efficiency. This ensures that the product meets all specified requirements and is ready for client review.

Feedback & Adjustments

After testing, the prototype is shared with the client for review. Based on their feedback, we make any necessary adjustments to refine the design and enhance product performance.

Final Sample Production

Once all changes are approved, we produce a final sample. This version is subject to further testing to ensure it fully meets the client's expectations and can be scaled for production.

Mass Production & Support

With the final design confirmed, we begin mass production. Throughout this phase, we maintain strict quality control and provide ongoing technical support to ensure smooth implementation and customer satisfaction.

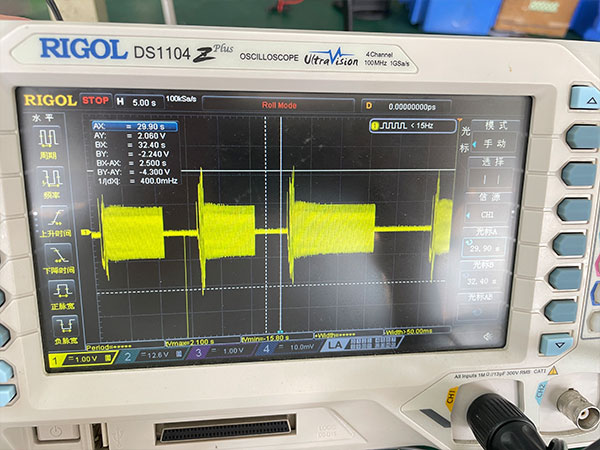

Technical advantages

Achieve precise temperature regulation with control accuracy up to ±0.01℃, ensuring optimal performance and longevity of your laser systems.

Reliable Performance in Extreme Conditions

Built to perform in demanding environments, our chillers ensure reliable operation even under extreme temperature and workload conditions.

Why Choose Coolingstyle Industrial Chiller

- Achieve Precision with ±0.1℃ Accuracy: You can count on exact temperature control, ensuring your equipment operates at peak efficiency.

- Over 100 Customizable Solutions: Whether you need cooling for small or large-scale applications, we’ve got you covered with more than 100 tailored options.

- Leverage Our 30+ R&D Experts: Your projects benefit from our team’s extensive experience in electronics, structural design, and software development.

- Save Up to 20% on Energy Costs: With our advanced frequency conversion technology, your operations become more cost-effective.

- Built on 100+ Patents: You gain from proven technology that delivers reliability and innovation in every unit.

- 1-Stop Solution from Concept to Production: You can streamline your project with our comprehensive design-to-production service, all under one roof.

- Trusted by Clients in 40+ Countries: You can rely on our global support network to keep your operations running smoothly.

FAQ's About Custom Chiller Solutions

To customize a cooling system, please provide details about your cooling capacity requirements, temperature range, application specifics, environmental conditions, space constraints, and any special features you need. This information helps us design a solution tailored to your exact needs.

Cooling capacity is typically measured in watts (W) or British Thermal Units per hour (BTU/hr). It depends on the amount of heat your equipment or process generates. Our team can help you calculate this based on your specific application details.

The best type of chiller depends on your application, cooling needs, and environmental conditions. We offer various options, including water chillers, air-cooled chillers, and micro chillers, and can recommend the best solution based on your requirements.

Yes, our chillers can be integrated with existing systems. We offer models with various control interfaces, such as RS485 or RS232, to ensure compatibility and seamless operation with your current equipment.

Please provide measurements of the available space, including height, width, and depth. Consider access and clearance for installation and maintenance, and note if the chiller will be floor-mounted, wall-mounted, or rack-mounted.

Environmental factors such as ambient temperature, humidity levels, and exposure to dust or corrosive materials can affect chiller performance and longevity. Providing detailed information about your operating environment helps us recommend the most suitable chiller design.

Yes, our chillers are designed for energy efficiency, incorporating features such as intelligent frequency conversion and optimized compressor design. Let us know your energy efficiency goals, and we can customize a solution to meet them.

Our chillers can be customized to match various power supply options, such as voltage and phase. Please provide details about your available power supply to ensure compatibility with the chiller.

The lead time for custom chiller orders varies based on the complexity and specifications of the project, typically ranging from 4 to 8 weeks. We will provide a more precise timeline once your order details are confirmed.

We offer a range of special features, including remote monitoring, alarms, redundant systems, and specific cooling mediums like water or glycol. Let us know your specific needs, and we can incorporate these into your custom chiller design.

Comprehensive One-Stop Design and Production

At Coolingstyle, we offer a full-spectrum, one-stop design service that takes your project from initial concept drawings all the way to mass production. Our complete in-house R&D team includes experts in electronics, structural engineering, hardware, and software development, ensuring seamless integration and high-quality results. With extensive experience across various industries, our team excels in transforming complex ideas into innovative, reliable products. Our multidisciplinary approach allows us to optimize every aspect of the design and manufacturing process, giving you a competitive edge with tailored solutions that are ready for market.

Join Us at the 2025 Munich Laser World of Photonics!

We’re excited to announce that Coolingstyle will be exhibiting at the 2025 Munich Laser World of Photonics, the leading trade fair for photonics technologies. We invite you to visit our booth, explore our latest innovations in industrial chillers, and discuss how we can support your cooling needs.

How to Customize a Cooling System to Meet Your Needs: A Step-by-Step Guide

Table of Contents

Customizing a cooling system for your specific requirements can significantly enhance efficiency, performance, and reliability in your operations. At Coolingstyle, we specialize in providing tailored cooling solutions that meet the unique demands of various industries. In this blog, we will guide you through the entire process of customizing a cooling system, from the initial consultation to final delivery.

Step 1: Initial Consultation and Needs Assessment

The first step in customizing a cooling system is understanding your specific needs. During the initial consultation, we will discuss several key factors to ensure we fully understand your requirements:

- Cooling Capacity: We will ask about the amount of heat that needs to be removed from your application, which is typically measured in watts (W) or British Thermal Units per hour (BTU/hr).

- Temperature Range and Precision: We’ll need to know the desired operating temperature range and how precise the temperature control needs to be, such as ±0.1°C.

- Application Details: Understanding the specifics of your application, including the type of equipment being cooled and its operational environment, helps us recommend the best chiller type.

- Space and Installation Constraints: We will ask about the available space for the chiller and any specific installation requirements, such as mounting preferences or access limitations.

- Special Features: Let us know if you need any special features, such as remote monitoring, alarm systems, or specific cooling mediums like water or glycol.

Step 2: Site Evaluation and Feasibility Study

After the initial consultation, our team will conduct a site evaluation to assess the environmental conditions and installation constraints. This step involves:

- Measuring Available Space: We will measure the available space for the cooling system and ensure there is adequate clearance for placement and operation.

- Assessing Environmental Conditions: We will evaluate ambient temperature, humidity levels, and potential exposure to dust, chemicals, or other harsh conditions.

- Power Supply Check: We will verify the available power supply, including voltage and phase, to ensure compatibility with the chiller system.

Step 3: Design and Engineering

Based on the information gathered during the needs assessment and site evaluation, our engineering team will begin designing your custom cooling system. This stage involves:

- System Design: We will design a system that meets your cooling capacity requirements, fits within your available space, and aligns with your temperature control needs.

- Component Selection: We will choose the appropriate components, such as compressors, heat exchangers, and control systems, to ensure optimal performance and energy efficiency.

- Customization Options: If you have requested specific features or modifications, we will incorporate these into the design.

Step 4: Proposal and Approval

Once the design is complete, we will provide you with a detailed proposal that includes:

- Design Specifications: A comprehensive overview of the proposed system design, including dimensions, cooling capacity, and any special features.

- Cost Estimate: A breakdown of the costs associated with the custom cooling system, including equipment, testing, and any additional services.

- Timeline: An estimated timeline for prototype development, testing, and potential mass production.

After reviewing the proposal, you can provide feedback or request modifications. Once you are satisfied with the design, we will move forward with your approval.

Step 5: Prototype Development and Testing

After receiving your approval, we will develop a prototype of the custom cooling system. This stage includes:

- Prototype Manufacturing: Our team will create a prototype based on the approved design specifications, using high-quality materials and advanced manufacturing techniques.

- Initial Testing: The prototype will undergo rigorous testing to ensure it meets all performance, safety, and reliability standards. This includes testing the cooling capacity, temperature control accuracy, and system durability under various conditions.

- Client Review and Feedback: You will have the opportunity to review the prototype and provide feedback. Any necessary adjustments will be made to ensure the final product meets your exact specifications.

Step 6: Final Approval and Mass Production

Once the prototype has been tested and approved, we will proceed with the mass production phase:

- Final Design Adjustments: Based on the feedback from the prototype testing, we will make any final adjustments to the design.

- Mass Production: Our team will begin mass production of the custom cooling system, ensuring consistent quality and reliability for every unit.

- Quality Control: Each unit will undergo rigorous quality control checks throughout the production process to ensure it meets our high standards and your specific requirements.

Step 7: Shipment and Delivery

After production is complete, we will prepare your custom cooling system for shipment:

- Packaging: We carefully package each unit to ensure safe transport and delivery to your location.

- Shipment Coordination: We coordinate with reliable shipping partners to ensure timely and efficient delivery of your cooling system.

- Delivery Confirmation: Once your system is shipped, we will provide tracking information and keep you informed about the delivery status.

Conclusion

Customizing a cooling system with Coolingstyle is a collaborative and detailed process designed to ensure you receive a solution that perfectly fits your needs. From initial consultation to prototype development and final shipment, we are committed to providing you with a high-quality, reliable cooling system that enhances your operations.

Ready to get started? Contact us today at info@coolingstyle.com or visit our website at www.coolingstyle.com to begin the process of customizing your cooling system. Our team is here to help you every step of the way.

Ask for a quote

Interested to communicate for further details? Just submit your details and we’ll be in touch shortly. You can also email us if you would prefer.