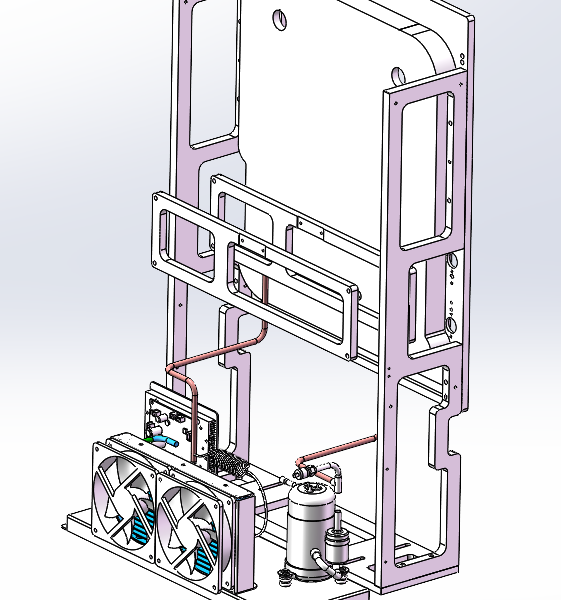

As industries seek more efficient and sustainable cooling solutions, an increasing number are opting to eliminate the traditional water medium in favor of directly using refrigerants to cool heat sources. This method enhances cooling efficiency, reduces energy loss, and simplifies the system. At Coolingstyle, we’ve responded to this shift by developing custom direct cooling solutions for a wide range of applications.

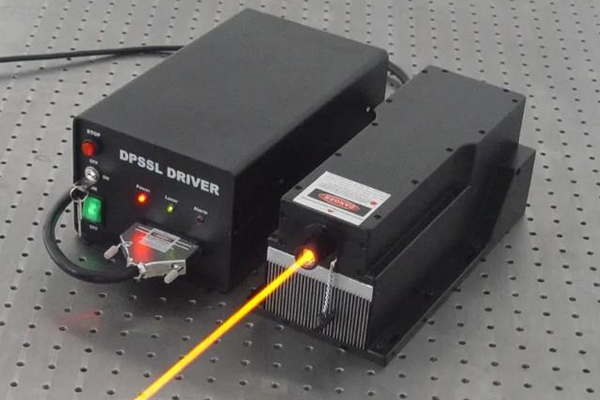

1. Direct Cooling for Laser Modules

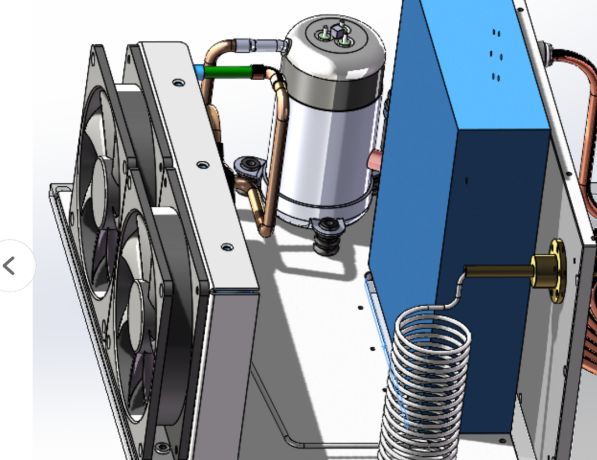

In this solution, a refrigerant-based cooling module is integrated directly into the laser system. The refrigerant flows through pipes embedded in the cooling plate, providing uniform cooling to the power supply, laser modules, and other critical components. By utilizing heat distribution mapping and precise control systems, this design ensures local temperature control accuracy within ±0.5℃. This solution is ideal for applications requiring high thermal precision. Learn more about our laser cooling solutions.

2. Direct Cooling for Medical Liquid Storage Bags

This solution is designed to maintain a stable, low-temperature environment for medical liquid storage bags. The system integrates seamlessly with the host computer for intelligent temperature monitoring, ensuring compliance with laboratory noise standards and preventing condensate water from damaging sensitive medical components. Our solution is engineered for both efficiency and reliability, ensuring optimal performance in critical medical applications.

3. Direct Cooling for Laboratory Chemical Reaction Bath Pots

For laboratory settings where precise temperature control is required, this solution cools the silicon oil inside a chemical reaction bath pot by passing refrigerant through an aluminum plate. A key challenge in this application is preventing leaks between the copper refrigerant pipes and the aluminum bath pot. To address this, we use advanced techniques such as embedding copper blocks, pre-welding, and sealing rings to ensure both structural integrity and ease of installation.

Why Choose Direct Cooling Technology?

At Coolingstyle, we pride ourselves on delivering tailored, high-efficiency cooling solutions that eliminate the need for an intermediary water chiller, directly using refrigerants for superior thermal management. This approach not only boosts energy efficiency but also reduces operational costs and enhances the overall sustainability of your cooling systems.

Our direct cooling solutions are designed to meet the unique needs of various industries, offering improved performance, reliability, and ease of integration. We are committed to ongoing innovation and customization, ensuring that our products consistently exceed customer expectations.

For more information on our direct cooling technologies and to explore customization options, visit our website or contact our team. Let Coolingstyle help you optimize your cooling processes and achieve greater operational efficiency.