Lasers produce a copious amount of heat during their operation. And to get the best performance, high precision temperature control is a vital characteristic to maintain.

External cooling in lasers is frequently used in industrial production. They help maintain or even improve laser performance. Fan-cooled lasers exist. However, they are usually replaced with cool chillers that remove additional heat and keep internal laser components safe.

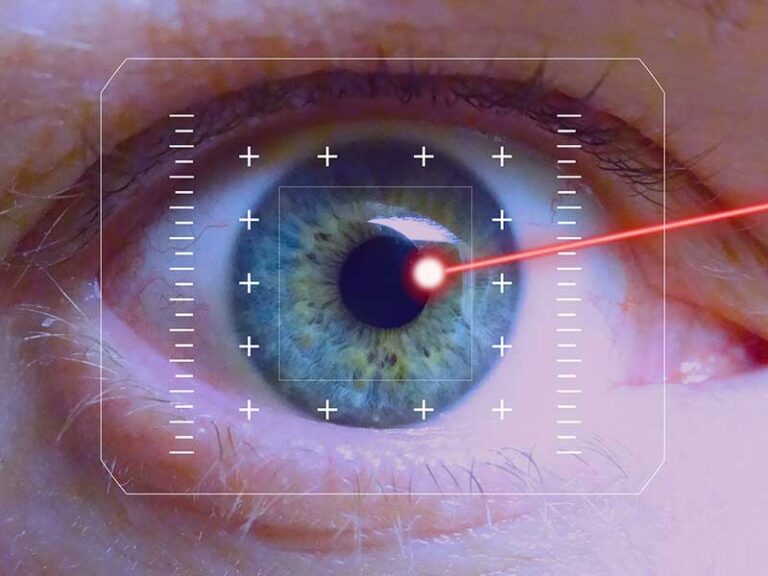

What Are Lasers Used for?

The word “laser” means “light amplification by the stimulated emission of radiation.” Lasers are now widely employed in large-scale industries such as:

▪ Barcodes have spread from store to store since 1952.

▪ Welding, printing, marking industries.

▪ Across the world, military and telecommunication applications utilize lasers.

▪ Healthcare facilities of all kinds.

Do Chillers Protect the Lasers from Overheating?

Chillers are used to remove the heat. It is necessary to cool the industrial lasers’ resonator power electronics and optics system to remove the generated heat. These Vapor compression water chillers are often used in laser systems. Here the resonator and optics working temperatures must be below ambient.

High precision chiller helps increase the life expectancy of equipment by impeding overheating. Maintaining a constant temperature keeps the laser efficiency and ensures consistent performance throughout its operating life-cycle.

Why Do Lasers Need to Have Chiller Cooling Mechanisms?

A conventional chiller cooling mechanism is made with a temperature controller, a coolant pump, and a heat exchanger. The laser may not receive the cooling it needs to generate an ideal beam if these three components are not adequately matched to the laser system’s cooling capacity requirements.

A more precise heat-removal method relies on compressor, condenser, capillary throttle, and evaporator. This all-in-one unit functions as the system’s foundation. The cooling capacity varies from 400w to tons watts based on different chiller unit. It makes Portable heat management systems very reliable.

Are Lasers Affected by High Temperatures?

The laser system’s performance suffers when the temperature rises. Total optical conversion efficiency is reduced as operating temperature increases. The wavelength of light energy emitted by each emitter must lie inside a narrow region. Manufacturers of lasers employ chillers to keep their products from overheating. This overheating may otherwise lead to damage or lower quality outcomes.

Overheating a laser’s light-emitting facets may also degrade the quality and amount of the laser’s light output. Laser quality suffers as a consequence.

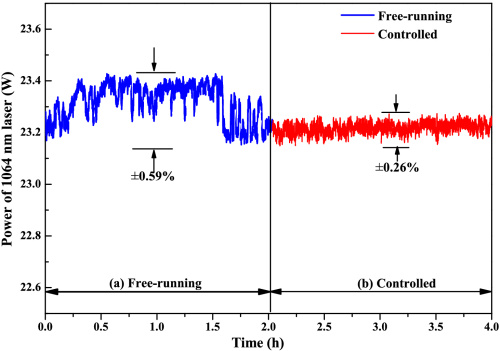

What Impact Does the Accuracy of the Industrial Chiller Has on Laser Performance?

When the temperature fluctuates, a laser’s performance and lifespan are affected. As well as production outputs and customer satisfaction. Heat can reduce laser-beam precision and distort laser components to a less accurate result.

Some cooling systems use pumps with a higher pulsating rate. Pulsating pumps still provide the cooling needed for the design, but they do it at a high vibration level. This causes a less focused laser beam and worse quality performance in laser systems. Therefore, Lasers require a precise temperature control.

Do Lasers Have Different Requirements for Temperature Control Precision?

It’s important to note that the lasers we use in our superstores differ significantly from the ones we use in factories. It requires more extensive and more powerful lasers with many robust cooling systems.

Makers of refrigerated recirculating chillers regulate the flow of refrigerant to the heat exchanger. This way, they can achieve different water temperature ranges. They also maintain variable precision and stability at the output coolant stream.

With a thermostatic expansion valve, a solenoid valve, and a hot gas bypass valve, a more efficient design may be possible. High-pressure liquid refrigerant flows into a low-pressure heat exchanger via an expansion valve. It then adjusts its orifice size in response to the heat load. Allows maximal cooling capacity at any specified temperature in the heat exchanger.

It is common for laser manufacturers to use more chillers with precise cooling and pumping requirements. It is to ensure optimal performance. This prevents machines from operating if any of the following conditions are not met- pressure, flow, or temperature.

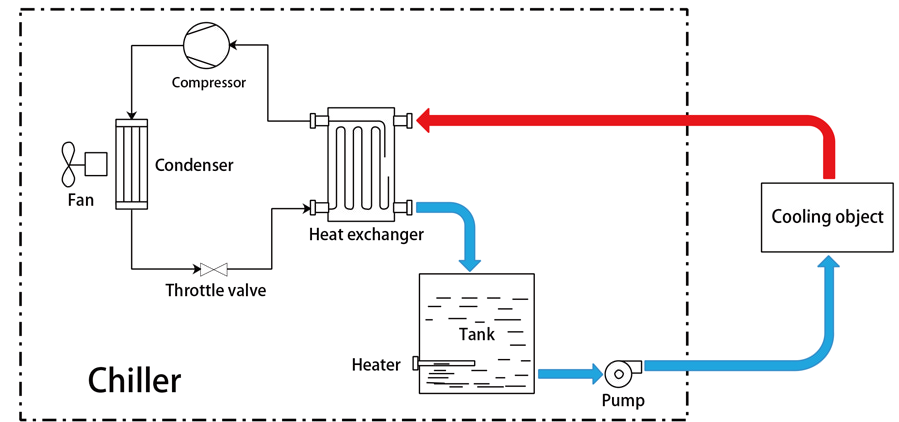

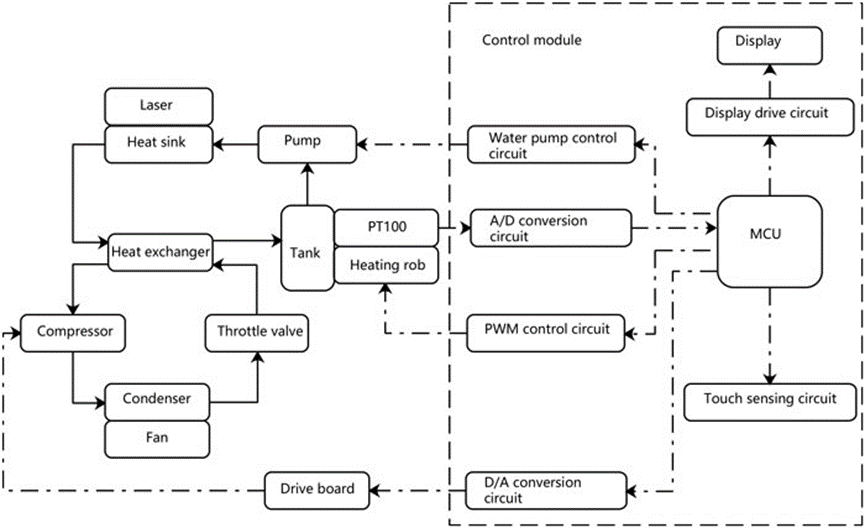

Air-cooled Chiller Temperature Control Principle

For a precision chiller, it is only necessary to keep the water temperature stable to ensure that the laser temperature is stable. The cooling of the water is achieved by the above mentioned cooling system and the heating of the water can be achieved by the electric heaters arranged inside the water tank. The temperature sensor feeds the sensed water temperature signal to the microcontroller after A/D conversion, and the microcontroller controls the compressor and the electric heater through an output circuit based on the relationship between the current actual water temperature and the desired target temperature to achieve a stable water temperature. In the control module, there is also a display screen and a touch-sensing circuit for human-computer dialogue. The user can observe the water temperature and the operation of the temperature control system in real time through the control module, and can also set the target cooling water temperature as required to meet the demands.

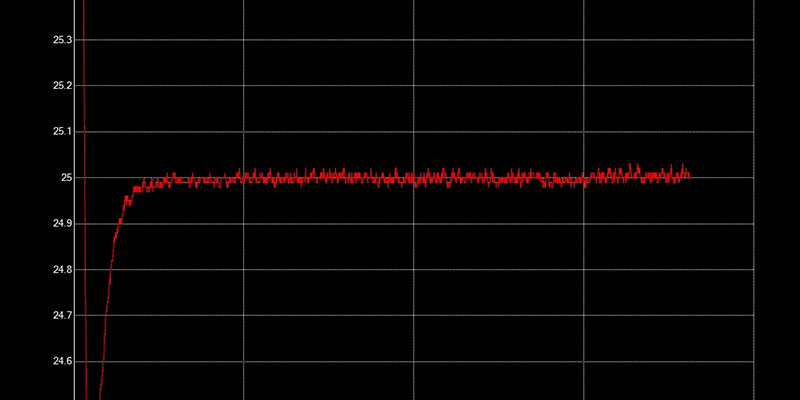

Recommendations

Coolingstyle’s air cooled chillers offers a wide range of cooling capacity options from 420W to 1200W. The cooling water temperature range is from 5-35℃. It adopts PID control to enable high precision temperaure control, which is up to ±0.1℃.

Final Verdict

Every laser we are familiar with today requires some type of cooling in order to perform smoothly and accurately. Thus choosing a chiller unit for the laser system is an absolute must-have for the laser system’s lifetime and accuracy. Welcome to contact us to choose the right chiller model for your laser cooling.

https://coolingstyle.com/udm/category/product/industrial-chiller/

Sources

· ASME: Application of Lasers.

· ADS: Benefits of Laser Treatment

· Wikipedia: Industrial use of Lasers

· PhotonicsView: Laser Cooling