When your system overheats or underperforms, the culprit is often an overlooked chiller sizing mistake1. Don’t let the wrong capacity cost you your productivity.

Choosing the right chiller capacity2 is critical—too small, and you risk overheating; too large, and you waste energy and money. It’s all about balance and precision.

If you’ve ever wondered why your cooling system seems inefficient despite high specs, you’re not alone. Let’s dive into what truly affects chiller performance3 and how to make the right choice.

What are the factors of chiller selection4?

A lot more goes into chiller selection4 than just cooling power. From your application’s load profile to ambient conditions—every detail counts.

To select the right chiller, you need to consider heat load5, application type, required temperature stability, flow rate, ambient temperature6, and installation environment.

Why it’s more than just capacity

Often, customers approach me asking for “the strongest” chiller. But the strongest doesn’t always mean the best. Selection starts with a clear understanding of your heat load5, which is the actual amount of heat your system produces. A good rule of thumb is: calculate, don’t estimate7.

Key factors to evaluate:

| Factor | Description |

|---|---|

| Heat Load5 | Total heat generated by the system or process needing cooling |

| Temperature Control Accuracy8 | Some applications like lasers or medical devices require ±0.1°C accuracy |

| Ambient Conditions | Higher room temperatures mean the chiller works harder |

| Flow Rate and Pressure | Flow must match the system’s internal resistance and cooling path design |

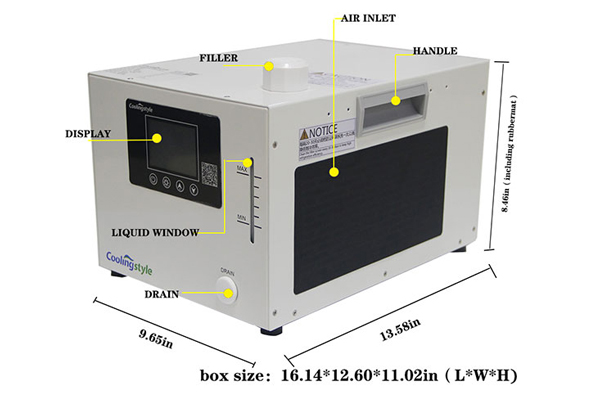

| Size and Footprint | Especially critical in mobile or integrated systems |

| Power Supply9 | Some systems require AC110V, others AC220V or even DC |

At Coolingstyle, we often tailor our chillers to match not only the cooling demand but also the unique form factor and power environment of each client. Overlooking just one of these variables can compromise the entire system’s performance.

What affects the efficiency of chillers?

Efficiency doesn’t just come from technology—it comes from using the technology correctly. And that starts with matching capacity to demand.

Chiller efficiency is affected by system design10, ambient temperature6, compressor type, heat exchanger performance, and how well the chiller matches the actual application load.

Common chiller efficiency killers:

-

Oversizing or undersizing11 – Too large, and the chiller short-cycles, wasting energy. Too small, and it runs continuously and overheats.

-

Incorrect flow rate12 – Poor matching between chiller and load can cause temperature swings and pump strain.

-

Ambient temperature extremes – If your environment is too hot, the chiller’s capacity drops unless designed for that range.

-

Lack of insulation – Uninsulated tubing or tanks leads to significant heat gain from the environment.

-

Dirty or blocked heat exchangers13 – This restricts heat transfer and stresses the compressor.

Our approach at Coolingstyle

We build our chiller systems with micro DC inverter compressors14 and intelligent PID control15, which adjusts the cooling output based on the real-time thermal load. It ensures that even in high-temperature environments or precision-required applications, the system performs efficiently and reliably.

We also apply PCM (phase change material)16 for buffering sudden thermal shocks in certain custom solutions. These details may seem small, but they all serve one goal—stabilize output with the least power draw.

The Importance of Choosing the Right Chiller Capacity

I’ve seen it too many times: customers overspend on a powerful chiller that ends up cycling on and off, or worse, underinvest and face equipment damage. This choice makes or breaks your system.

Right-sizing your chiller17 is the foundation for stable temperature control18, long equipment life, and energy efficiency19. Guesswork here leads to high costs and system failures.

Why precision sizing20 matters

A mismatch between the chiller capacity2 and the actual load introduces all kinds of risks:

-

Undersized Chiller21: Can’t keep up, leads to overheating, poor product quality, or equipment failure.

-

Oversized Chiller22: Wastes energy, costs more upfront, and can cause unstable temperature swings from rapid cycling.

| Problem | Undersized Chiller21 | Oversized Chiller22 |

|---|---|---|

| Overheating | High risk | Low risk |

| Efficiency | Low | Low |

| Lifetime | Shortened due to overload | Shortened due to cycling |

| Cost | Lower upfront, higher long term | High upfront, inefficient use |

| Stability | Inconsistent temps | Inconsistent temps |

How we help at Coolingstyle

Before quoting or designing a product, we dig deep into your working conditions23. Are you using it with a 20W laser or a medical cooling pad? Is the environment climate-controlled or outdoors? These questions shape our final recommendation.

Most of our chillers—like the Q580 or Q4U3 series—are designed with built-in safety buffers24, allowing up to 10-15% margin over the calculated load to handle spikes without wasting energy. We also optimize form factor, temperature stability, and pump flow based on what you actually need—not just what looks powerful on paper.

In one case, a Taiwanese client asked for a 1000W unit. After detailed calculations, we recommended our 580W model, and it outperformed their expectations while saving 20% on electricity costs. This is why precision beats assumption25.

Conclusion

Right-sizing your chiller17 ensures performance, efficiency, and longevity26. At Coolingstyle27, we don’t just sell chillers—we build solutions that fit perfectly.

-

Avoiding chiller sizing mistakes can save you money and improve system performance. Check this resource for expert advice. ↩

-

Understanding chiller capacity is essential for optimizing cooling efficiency and preventing system failures. Explore this link for in-depth insights. ↩ ↩

-

Improving chiller performance is key to energy efficiency and cost savings. Discover strategies to enhance your system’s effectiveness. ↩

-

Understanding the best practices for chiller selection can help ensure optimal performance and efficiency in your cooling system. ↩ ↩

-

Calculating heat load accurately is crucial for selecting the right chiller, ensuring it meets your cooling needs effectively. ↩ ↩ ↩

-

Exploring the impact of ambient temperature on chiller performance can help you make informed decisions for your cooling system. ↩ ↩

-

Calculating rather than estimating ensures accuracy in HVAC design, leading to better performance and efficiency. Discover more here. ↩

-

Temperature control accuracy is vital for sensitive applications. Discover how it impacts performance and reliability in cooling systems. ↩

-

Power supply requirements can vary significantly. Learn about the implications of different power supplies on cooling system design and efficiency. ↩

-

Exploring system design’s role can lead to better chiller setups and improved energy efficiency. ↩

-

Understanding the impact of chiller sizing can help optimize energy efficiency and performance. ↩

-

Learn how flow rate influences chiller efficiency and how to avoid common pitfalls. ↩

-

Discover the importance of maintaining heat exchangers for optimal chiller operation and energy savings. ↩

-

Explore this link to understand how micro DC inverter compressors enhance energy efficiency and performance in cooling systems. ↩

-

Learn about intelligent PID control and its role in optimizing cooling systems for better efficiency and reliability. ↩

-

Discover the advantages of PCM in cooling applications and how it buffers thermal shocks effectively. ↩

-

Understanding the significance of right-sizing can help you avoid costly mistakes and ensure optimal performance of your cooling system. ↩ ↩

-

Stable temperature control is crucial for efficiency and product quality; exploring this can enhance your operational knowledge. ↩

-

Learning about energy efficiency can lead to significant cost savings and environmental benefits in your operations. ↩

-

Understanding precision sizing can help you avoid costly mistakes in chiller selection and improve system efficiency. ↩

-

Understanding the risks associated with undersized chillers can help you make informed decisions for your cooling needs. ↩ ↩

-

Exploring the disadvantages of oversized chillers can save you from costly mistakes and improve energy efficiency. ↩ ↩

-

Understanding working conditions is crucial for tailored solutions. Explore this link to enhance your knowledge on effective assessments. ↩

-

Learn how built-in safety buffers can enhance performance and energy efficiency in equipment, ensuring reliability and safety. ↩

-

Discover the significance of precision in product design, which can lead to better outcomes and cost savings for clients. ↩

-

Exploring this topic can provide insights into optimizing your chiller’s operation and maintenance for better results. ↩

-

Discovering Coolingstyle’s offerings can help you find tailored solutions that meet your specific cooling needs.

Proper cutting techniques[^7] are vital to maintaining the integrity of the material. A clean cut ensures that edges remain smooth and free from cracks or discoloration, which can be especially important when the acrylic will be used for display purposes. ↩