The 532nm green laser1 is widely used in scientific research, industrial processing, and medical applications due to its high brightness and visibility. Its core technology is based on diode-pumped solid-state (DPSS) lasers2, which use frequency doubling to convert 1064nm infrared light into 532nm green light. During operation, lasers generate heat, and accurately estimating this heat output is essential for designing an effective cooling system. This article explores the working principles of 532nm lasers and calculates their heat generation3.

1. Working Principles of 532nm Lasers

1.1 DPSS Laser Structure and Operation

The 532nm laser typically employs DPSS technology4, which consists of the following steps:

-

Pumping Process: An 808nm laser diode (LD) serves as the pump source, exciting a Nd:YAG (neodymium-doped yttrium aluminum garnet) or Nd:YVO4 (neodymium-doped yttrium orthovanadate) crystal.

-

1064nm Laser Generation: The pump light is absorbed by the crystal, causing neodymium ions (Nd³⁺) to transition to a higher energy state. When they return to the ground state, stimulated emission produces 1064nm infrared laser light5.

-

Frequency Doubling: The 1064nm laser passes through a nonlinear optical crystal (such as KTP, potassium titanyl phosphate), undergoing second harmonic generation (SHG)6 to halve the wavelength and produce 532nm green light7.

1.2 Characteristics of 532nm Lasers

-

High Brightness: 532nm green light7 is near the peak of human visual sensitivity (\~555nm), making it highly visible.

-

Wide Applications: Used in fluorescence excitation, laser alignment, laser displays, medical treatments, and scientific instruments.

-

Efficiency Limitations: Due to the nonlinear conversion process, overall electrical-to-optical efficiency typically ranges from 10% to 20%.

2. Heat Generation Calculation for 532nm Lasers

The total heat output of a laser primarily results from efficiency losses8 in various system components. The fundamental formula is:

Qtotal=Pinput−P532

Where:

-

Pinput is the electrical input power (W)

-

P532 is the output power of the 532nm laser (W)

2.1 Major Sources of Heat

| Source | Loss Mechanism | Typical Efficiency | Heat Contribution |

|---|---|---|---|

| Laser Diode | 808nm electrical-to-optical conversion | 50% | Unconverted energy generates heat |

| Laser Crystal | 808nm to 1064nm conversion | 75.9% | Quantum defect losses (808/1064) |

| Frequency Doubling | 1064nm to 532nm conversion | 50% | Unconverted 1064nm light absorbed as heat |

2.2 Example Calculation of Heat Generation

Assuming an input power of Pinput=1W, with a laser diode efficiency of 50% and a frequency doubling9 efficiency of 50%, the calculations proceed as follows:

-

808nm Pump Power: P808=0.5imesPinput=0.5W

-

1064nm Laser Power (considering quantum defect losses): P1064=0.759imesP808=0.3795W

-

532nm Output Power (with 50% doubling efficiency): P532=0.5imesP1064=0.18975W

-

Total Heat Generation: Qtotal=1W−0.18975W=0.81025W

3. Thermal Management for 532nm Lasers

3.1 Common Cooling Methods

-

Air Cooling: Uses fans to increase airflow and dissipate heat efficiently.

-

Water Cooling Systems10: Suitable for high-power lasers, offering enhanced heat dissipation and maintaining stable operating temperatures.

-

TEC (Thermoelectric Cooling)11: Uses Peltier modules for precise temperature control, often applied in compact precision instruments.

3.2 Coolingstyle’s Cooling Solutions

As a leader in precision temperature control, Coolingstyle provides high-performance chillers optimized for 532nm laser applications:

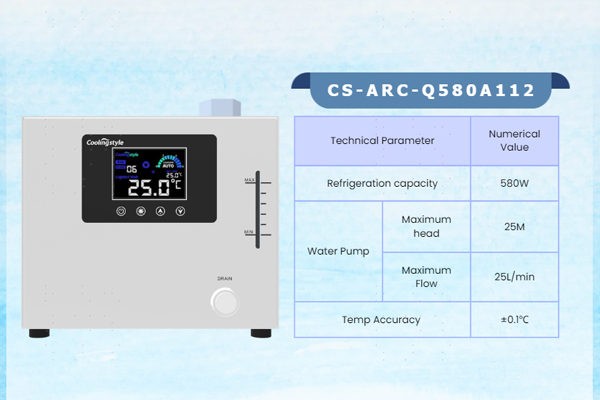

- Q580 Series Chillers12: High-precision temperature control (±0.1°C), ideal for laboratory and industrial laser applications.

- M160 Series Chillers: Designed for high-power laser cooling, offering superior heat dissipation.

For custom cooling solutions tailored to your specific laser system, contact our technical team to ensure optimal thermal management.

4. Conclusion

532nm lasers13 utilize DPSS technology4, converting 808nm pump light to 1064nm and subsequently doubling the frequency to produce green light. Due to multiple efficiency losses, their typical electrical-to-optical conversion efficiency is around 10% to 20%. Heat management is crucial, as most of the input power is converted into heat rather than laser output. Coolingstyle14 provides specialized cooling solutions to ensure stable and efficient laser operation by maintaining optimal temperature control.

-

Explore the diverse applications of 532nm green lasers in various fields, enhancing your understanding of their significance. ↩

-

Learn about the innovative technology behind DPSS lasers and their advantages in laser applications. ↩

-

Understanding heat generation in lasers is crucial for effective cooling system design; explore this topic for deeper insights. ↩

-

Explore this link to understand the fundamentals of DPSS technology and its significance in laser applications. ↩ ↩

-

Discover the importance of 1064nm infrared laser light in various applications, from medical to industrial uses, broadening your knowledge. ↩

-

Learn about the fascinating process of SHG and its role in laser technology, which is crucial for producing different wavelengths. ↩

-

Explore the diverse applications of 532nm green light lasers in various fields, enhancing your understanding of their significance. ↩ ↩

-

Efficiency losses directly impact the performance of lasers. Learn more about these losses to improve your laser system’s design. ↩

-

Frequency doubling is a key process in laser technology. Discover how it enhances laser output and efficiency by following this link. ↩

-

Explore the advantages of water cooling systems for lasers, especially in high-power applications, to enhance performance and longevity. ↩

-

Learn about TEC technology and its role in precise temperature control for lasers, crucial for maintaining optimal performance. ↩

-

Discover the high-precision capabilities of Q580 Series Chillers, designed specifically for laser applications, ensuring optimal thermal management. ↩

-

Exploring this link will provide insights into the diverse applications and advantages of 532nm lasers in various fields. ↩

-

Discovering Coolingstyle’s offerings can help you find effective cooling solutions to improve laser performance and longevity. ↩