Efficient cooling is critical for maintaining the performance and longevity of CO2 RF lasers. As highlighted by Philip Preston, president of PolyScience, temperature control plays a key role in stabilizing laser output. This is especially relevant as lasers convert only 10-20% of energy into light, with the remaining energy transforming into waste heat. Without effective heat dissipation, rising temperatures in the laser’s discharge area can negatively affect performance, output stability, and lifespan.

Why Cooling Is Essential for CO2 RF Lasers

Impact of Heat on Laser Stability

- Thermal Effects: Elevated temperatures in the laser discharge area increase molecular activity, depleting upper energy levels and broadening the CO2 molecular spectrum. This results in:

- Decreased output power

- Unstable laser performance

- Ideal Temperature Range: Research indicates CO2 RF lasers achieve optimal photoelectric conversion efficiency when the laser gas temperature is maintained between 400K and 500K.

Common Cooling Methods

- Air-Cooled Heat Dissipation

- Used primarily for low-power lasers (≤100W).

- Relies on fans to dissipate heat but is less effective for higher power outputs.

- Water-Cooled Heat Dissipation

- Suitable for all power ranges, especially high-power lasers.

- Transfers waste heat to the coolant via conduction, ensuring more efficient cooling.

Prolonging CO2 Laser Tube Life with Water Chillers

Coolingstyle’s 4U Rack-Mount Chiller offers a robust solution for laser cooling. Proper water cooling:

- Prolongs the lifespan of laser tubes.

- Enhances efficiency by maintaining stable temperatures.

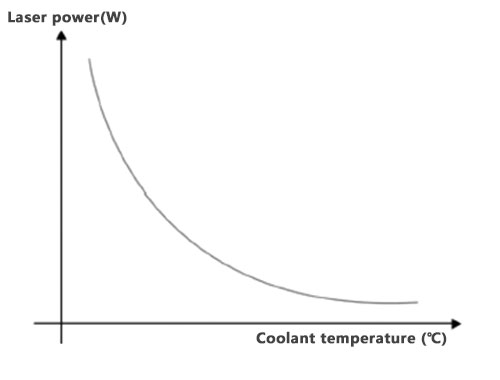

Effect of Coolant Temperature on Laser Power

According to Newton’s Law of Cooling (Ф = Α*η*Δt):

- The greater the temperature difference (Δt) between the coolant and discharge area, the more efficient the cooling.

- A 1°C increase in coolant temperature can reduce laser power by 0.5-1%.

Key Considerations:

- Overcooling Risks: Coolant temperatures set too low may cause condensation on the laser surface, affecting functionality and potentially reducing the laser’s lifespan.

- Optimal Coolant Temperature: Coolingstyle recommends 25±2°C, with adjustments for seasonal variations:

- Summer: Avoid condensation by setting to 28±2°C.

- Winter: Maintain a minimum coolant temperature of 5-10°C to prevent freezing.

Choosing the Right Water Chiller

To balance laser power and stability, Coolingstyle offers a range of water chillers tailored to the laser industry:

Features of Coolingstyle Chillers:

- Cooling Capacity: From 200W to 1200W.

- Temperature Stability: ±0.1°C for precise control.

- Compact and Lightweight: Easy integration into laser systems.

- Energy Efficiency: Low wattage consumption reduces operational costs.

- Easy Maintenance: User-friendly design for hassle-free operation.

Coolingstyle Chiller Options

- 420W and 580W Cooling Capacity

- 400W and 500W Cooling Capacity

- 4U Rack-Mount Chiller

- Compact and efficient for medium-scale applications.

- 1000W and 1200W Cooling Capacity

- 5U Rack-Mount Chiller

- Designed for high-power industrial laser systems.

Temperature Setting Recommendations

- Standard Conditions: Set the coolant temperature to 25±2°C for optimal laser stability.

- Seasonal Adjustments:

- Summer: 28±2°C to prevent condensation.

- Winter: Maintain a circulating temperature of 5-10°C to save energy and avoid freezing.

- Antifreeze Use: Use professional-grade antifreeze if necessary; avoid ethanol as it may damage the system.

Conclusion

Proper cooling is essential to maintaining laser performance and stability. Coolingstyle’s advanced water chillers, with their precise temperature control and energy efficiency, are tailored to meet the unique demands of CO2 RF lasers. By selecting the right chiller and maintaining optimal coolant temperatures, users can extend the life of laser tubes, improve output power, and achieve consistent results in manufacturing and industrial applications.

For more information about the coolant choice, you may visit this blog for reference: